Vibrant Colors DTF Transfers: Expert Tips for Success

Vibrant Colors DTF Transfers are revolutionizing the world of textile printing, allowing creators to produce stunning, high-quality designs with ease. Understanding DTF transfer techniques is crucial for achieving color vibrancy that captivates customers and elevates any apparel. In the fast-paced realm of custom printing, knowing the best DTF printing tips can make all the difference in the final product’s appearance. By mastering the intricacies of Direct to Film printing, artisans can enhance fabric transfer vibrancy, ensuring that their prints stand out. This introduction lays the groundwork for exploring the essential strategies and insights needed to achieve breathtaking color results with DTF transfers.

Direct to Film transfers, often referred to simply as DTF printing, offer an innovative method for applying graphics onto various fabric surfaces. This technique is celebrated for its ability to deliver vibrant hues that are essential for capturing the attention of a diverse audience. Understanding the nuances of this printing process, including the correct ink selection and appropriate film types, is vital for anyone looking to enhance their digital textile creations. Moreover, the effectiveness of fabric transfer methods hinges on proper curing and application techniques, making it imperative to master these aspects. In this guide, we will dissect the best practices that elevate your DTF print quality and ensure your designs make a lasting impression.

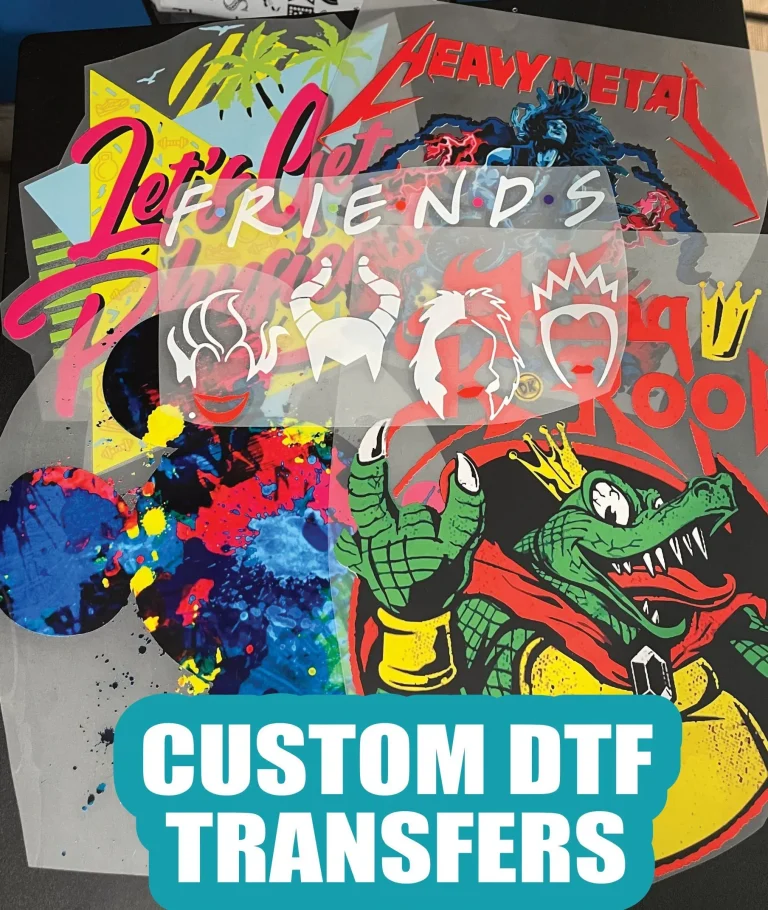

Vibrant Colors DTF Transfers: The Key to Successful Custom Printing

When it comes to vibrant colors in DTF transfers, selecting the right materials and techniques is crucial. DTF printing enables intricate designs to be infused onto fabrics with remarkable depth and brilliance. The cornerstone of achieving these eye-catching results lies in choosing high-quality inks combined with the appropriate transfer films. This synergy amplifies color vibrancy, enabling designs to pop with clarity and detail, ultimately appealing to customers seeking custom printed textiles.

To fully harness the potential of vibrant colors in DTF transfers, one must understand how each component interacts. For instance, a glossy film can accentuate the saturation of colors, revealing a luminous finish that draws attention. Likewise, the use of pigment-based inks specifically designed for DTF applications enhances not only the vibrancy but also the durability, ensuring that colors remain intact even after multiple washes. These factors combined allow businesses and hobbyists alike to produce standout pieces.

Understanding DTF Transfer Techniques for Color Vibrancy

DTF transfer techniques play a pivotal role in achieving the desired vibrancy in prints. Unlike traditional methods, DTF utilizes a specialized PET film that retains high-quality ink, leading to colorful and detailed outcomes. The success of these techniques hinges on a well-executed printing process, where the right balance of temperature and pressure during the curing phase is essential. This ensures that the inks bond effectively with the fabric, thereby enhancing the vibrancy of the final product.

During the DTF transfer process, the design is printed onto the film using specific inks that are not only vibrant but also durable. For those looking to attain the next level of vibrancy, it is recommended to experiment with various techniques, such as adjusting the curing temperature and pressure settings. Each fabric type might respond differently, making testing essential to discover the optimal setup that maximizes color output.

Achieving Color Vibrancy: Importance of Quality Materials in DTF Printing Techniques

The success of DTF printing in delivering vibrant colors is significantly influenced by the quality of the materials used. High-quality pigment-based inks provide better adhesion and color retention than their subpar counterparts. Furthermore, DTF films vary in finish—whether matte or glossy—influencing how colors appear on the fabric. A glossy finish usually enhances brightness and color depth, ideal for designs that need to stand out. On the other hand, matte films can help to create a more subdued aesthetic, depending on the desired outcome.

As you select your materials, it’s also critical to consider the compatibility of your inks and films with your fabric. Each combination may yield different results, so thorough testing is beneficial. By prioritizing quality and ensuring compatibility across inks, films, and fabrics, one can achieve prints that emit vibrancy and maintain longevity, ultimately satisfying customer expectations.

Essential DTF Printing Tips for Enhancing Color Quality

To achieve the best results in DTF printing, there are several tips and tricks that can significantly enhance color quality. Start by pre-treating fabrics to improve ink adherence, which can prevent common issues such as bleeding or dullness in prints. Options such as adhesive sprays or pre-coatings can be utilized to optimize the bonding between the ink and fabric. This added preparation step can make a noticeable difference in the vibrancy of the colors in your transfers.

Another key tip involves careful fabric selection. Different materials react uniquely with DTF inks and films, so ensuring that you use a fabric that’s suitable for DTF applications is essential. Cotton and polyester blends tend to yield fantastic results, as they absorb the inks well. Additionally, always ensure that the fabric is clean and free from oils or contaminants before applying transfers, as these can hinder the vibrancy and overall appearance of the final product.

Choosing the Right Transfer Film for Optimal Color Design

Selecting the right transfer film is paramount in achieving optimal color design in DTF printing. The thickness and finish of the transfer film can dramatically influence the vibrancy of your prints. Glossy films often amplify color saturation, making them ideal for bright, bold designs intended to attract attention. Conversely, matte films provide a more subdued effect, which may be preferable for subtler designs.

In addition to finish, the thickness of the film plays a significant role in the end result. Thicker films can handle more ink without bleeding, ensuring that ink application remains vibrant and clean over time. When choosing your transfer film, consider testing multiple options to observe how different brands and types react with your inks and fabrics. This experimentation can lead to discovering the perfect combination for achieving stunningly vibrant results that will delight customers.

Curing Methods: Key for Unlocking Vibrant Colors in DTF Printing

The curing method applied during DTF printing is a crucial aspect that cannot be overlooked if you aim to achieve vibrant colors in your prints. Proper heat pressing techniques ensure that the colors bond effectively with the fabric, facilitating the vivid output desired. Typically, DTF transfers call for specific temperature and pressure settings that must be adhered to—usually within the range of 160°C to 180°C (320°F to 355°F) at a medium to high pressure, depending on the fabric type.

Additionally, proper curing times help lock in the vibrancy, making sure that the designs remain bright even after several washes. Experimenting with different curing durations and understanding how your materials react can aid in achieving optimal results. By mastering the curing process, you can ensure that your DTF transfers boast colors that stand out, ultimately solidifying the quality of your final product.

Application Techniques: Ensuring Clean and Vibrant DTF Transfers

When applying DTF transfers, the techniques used in the application phase are just as critical as the preceding steps. Properly preparing the fabric by ensuring it is clean and free of residues is paramount. Contaminants such as oils or dust can severely affect the adhesion of the ink to the fabric, leading to dull or patchy prints. Pre-treating fabrics not only enhances adherence but can significantly improve the vibrancy of your designs.

Moreover, paying attention to the application pressure during the transfer process is vital to achieving vibrant prints. When applying the transfer, consistent pressure ensures an even transfer of ink, which is crucial for maintaining a vibrant appearance. Taking the time to focus on these application techniques will yield results that not only meet but exceed expectations in terms of vibrancy and quality.

Frequently Asked Questions

What are the best practices for achieving vibrant colors in DTF transfers?

To achieve vibrant colors in DTF transfers, it’s crucial to use high-quality pigment-based inks, select the right transfer film (glossy for more saturation), and follow precise curing guidelines, including maintaining the correct temperature and pressure during the application process.

How does the choice of inks affect the vibrancy of DTF transfers?

The choice of inks is vital for achieving vibrant colors in DTF transfers. High-quality, pigment-based inks provide better adhesion and color saturation compared to lower-quality inks, enhancing the overall vibrancy and durability of the prints.

What role does the transfer film play in enhancing fabric transfer vibrancy?

The transfer film significantly impacts fabric transfer vibrancy. Glossy films enhance color saturation, while matte films may lead to a subtler appearance. Thicker films can also retain more ink, ensuring higher vibrancy after washing.

What temperature and pressure settings are recommended for optimal DTF printing results?

For optimal results in DTF printing, it is typically recommended to use a temperature range of 160°C to 180°C (320°F to 355°F) with medium to high pressure. These settings help ensure colors adhere properly and pop on the fabric.

How can I prepare my fabric for DTF transfers to achieve the best color vibrancy?

Pre-treating fabrics with adhesive spray or a light fabric coating can improve bonding and enhance vibrancy. Additionally, ensuring the fabric is clean and free of oils or dust is essential for better dye adherence during the DTF transfer process.

What are some common DTF printing tips to ensure color vibrancy in my designs?

Common DTF printing tips include testing various ink brands for vibrancy, using glossy transfer films for brighter outputs, experimenting with curing times and conditions, and participating in community forums for shared insights on improving DTF transfer quality.

| Topic | Key Points |

|---|---|

| Introduction | Vibrant colors in DTF transfers are achieved through technology, materials, and techniques. |

| Understanding DTF Technology | DTF uses a special film for rich colors and detail, crucial for attracting customers. |

| The Printing Process | The quality of inks, types of film, and curing methods affect vibrancy. |

| Choosing the Right Inks | High-quality, pigment-based inks provide better adhesion and durability. |

| Selecting the Right Transfer Film | Choose between matte and glossy for different finishes affecting color saturation. |

| Curing Methods | Heat pressing enhances color brilliance; temperature and pressure are critical. |

| Application Techniques | Pre-treating fabrics and keeping them clean are key to vibrant prints. |

| Expert Recommendations | Continuous testing and staying updated on trends can enhance DTF outcomes. |

Summary

Vibrant Colors DTF Transfers are a masterful intersection of technology and artistry, leading to striking results in custom printed textiles. The pursuit of vibrant colors in DTF transfers involves meticulous attention to detail in selecting high-quality inks, choosing the appropriate transfer films, and mastering the curing process. Manufacturers and hobbyists alike can enhance vibrancy and longevity by understanding the DTF printing process and utilizing expert techniques. Engaging in community knowledge-sharing further empowers users to stay at the forefront of this innovative printing method, ensuring their designs not only captivate but also endure.