UV DTF Technology: The Future of Custom Printing Innovations

At the forefront of modern printing technology is UV DTF technology, a groundbreaking method that merges the precision of UV printing with the flexibility of Direct-to-Film (DTF) applications. As industries increasingly turn to custom printing solutions for unique and personalized products, UV DTF technology is driving innovation in this field. Offering superior quality and vibrant color reproduction, this method exceeds the capabilities of traditional printers by accommodating a diverse range of materials. Moreover, with a strong emphasis on eco-friendly printing practices, UV DTF technology utilizes sustainable materials and inks, aligning with the growing consumer demand for environmentally responsible products. In this article, we will delve into the expansive future of custom printing and the exciting advancements within UV DTF technology.

Known as Direct-to-Film UV printing, this innovative technology exemplifies the latest trends in custom graphics solutions. By harnessing UV printing innovations, this method allows for detailed and colorful designs to be applied across various substrates, from textiles to metal surfaces, demonstrating unmatched versatility. Additionally, trends in eco-conscious printing further highlight how UV DTF technology is not just about aesthetics but also about creating a sustainable printing future. With an increasing market demand for unique, high-quality prints, this printing technology stands out as a vital tool for businesses seeking to differentiate themselves. As we explore the landscape of DTF printing, the evolution towards more efficient and environmentally friendly methods reflects the shifting priorities in consumer preferences.

Understanding UV DTF Technology: A Comprehensive Overview

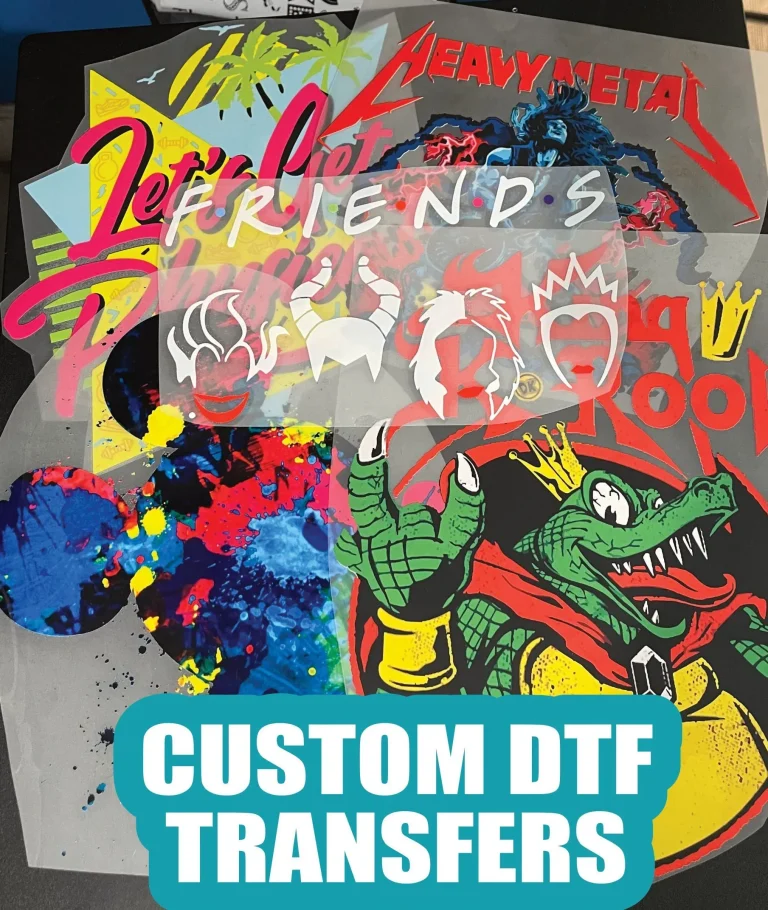

UV Direct-to-Film (DTF) technology is an innovative method of custom printing that combines the benefits of UV printing with the versatile applications of DTF techniques. This technology stands out for its high-resolution capabilities, enabling businesses to print intricate designs on a variety of substrates, including textiles, glass, metal, and plastic. As the demand for unique and personalized products increases, UV DTF technology is becoming the go-to solution for companies looking to offer customized services. The ability to achieve vibrant colors and detailed graphics sets it apart from traditional printing methods.

Furthermore, the implementation of UV DTF technology meets the needs of various industries, from fashion to promotional products. Unlike conventional printing techniques that may restrict material compatibility and design intricacy, UV DTF paves the way for greater creativity and flexibility. This adaptability ensures that businesses remain competitive in the ever-evolving market landscape, fulfilling customer demands for distinctive and high-quality products.

The Environmental Benefits of UV DTF Printing

One of the most significant advantages of UV DTF printing lies in its environmental impact. As consumers become more conscious of their ecological footprint, businesses are seeking eco-friendly printing solutions. UV DTF technology utilizes innovative inks that are free from volatile organic compounds (VOCs), dramatically reducing harmful emissions associated with conventional inks. This eco-friendly approach not only enhances the appeal of UV DTF printing but also positions companies as environmentally responsible players in the market.

Moreover, advancements in curing technologies enhance energy efficiency, enabling businesses to operate sustainably without sacrificing quality or speed. As industries transition toward greener methods, adopting UV DTF technology becomes a compelling choice for those aiming to cater to environmentally aware consumers, thus boosting their brand reputation and market share.

Technological Advances Shaping UV DTF Printing

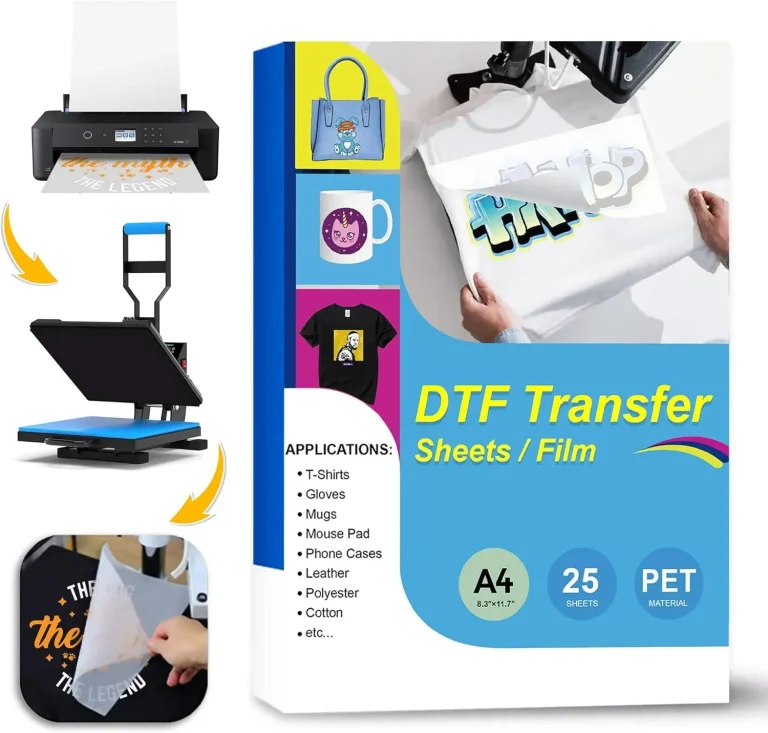

The landscape of UV DTF printing is continually evolving, marked by remarkable technological progress. One of the most significant advancements is the introduction of UV LED curing systems, which offer faster production rates paired with exceptional print quality. This innovation allows print businesses to maximize efficiency, reducing turnaround times while maintaining the integrity of complex designs. As a result, companies can handle higher volumes of orders, meeting the demands of a growing customer base without compromising on quality.

In addition to curing systems, enhancements in software integration have simplified the workflow for UV DTF printing operations. Intuitive software solutions help streamline printing processes, minimizing errors and increasing productivity. By optimizing their workflows, businesses can ensure smooth operations, allowing them to focus on delivering unique custom printing solutions while adapting to the fast-paced nature of the market.

The Rising Demand for Custom Printing Solutions

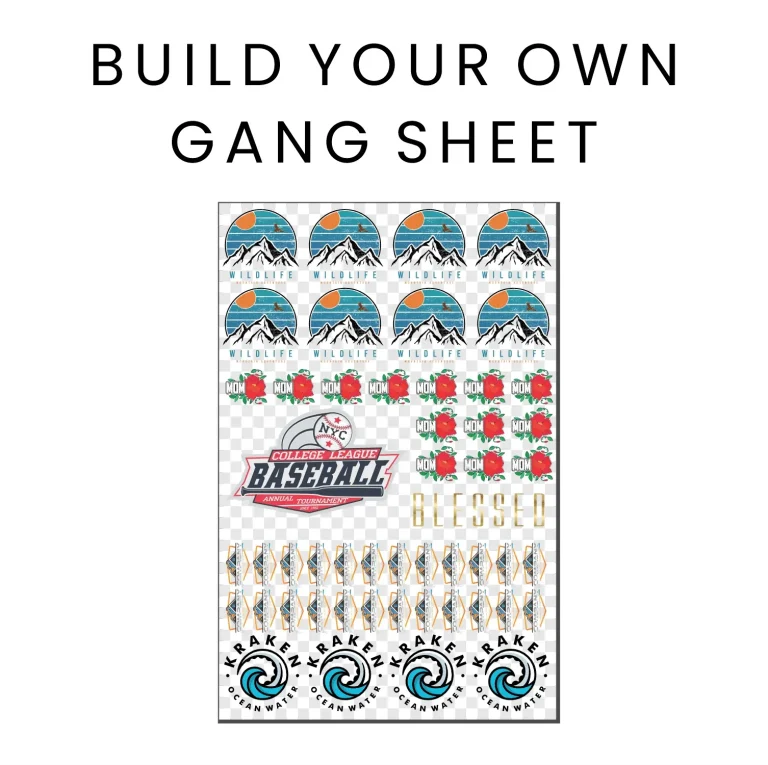

The custom printing market is witnessing unprecedented growth as consumer preferences shift towards personalized products. The increasing demand for unique and tailored items presents a lucrative opportunity for businesses that can leverage UV DTF printing technology. Reports indicate that this trend is only set to accelerate, with more enterprises recognizing the potential for profitability in offering customized services.

As consumers prioritize individuality, companies that embrace UV DTF technology position themselves at the forefront of innovation in the custom printing sector. The ability to deliver high-quality, one-of-a-kind products ensures that businesses can capitalize on this trend, meeting customer expectations while increasing their market presence.

Embracing Sustainability in Printing Practices

Sustainability is no longer just a trend; it’s becoming a standard expectation in the printing industry. Companies that adopt eco-friendly practices, such as UV DTF printing, can not only fulfill this demand but also differentiate themselves in a competitive market. Utilizing eco-friendly inks and energy-efficient curing systems aligns with the growing consumer preference for responsible production methods, enhancing brand loyalty among environmentally conscious consumers.

By prioritizing sustainable printing solutions like UV DTF, businesses can contribute towards reducing industrial waste and energy consumption. This approach not only meets regulatory requirements but also resonates well with customers, who are increasingly seeking brands that share their values regarding sustainability and environmental responsibility.

Training for Success in the UV DTF Printing Market

As UV DTF technology gains traction within the custom printing industry, investing in training for employees is crucial. Educational resources and training programs geared towards enhancing understanding of UV DTF processes can significantly improve productivity. Equipping employees with the skills needed to utilize this advanced technology ensures a smooth transition for businesses venturing into this innovative printing method.

By developing a knowledgeable workforce, companies can maximize their investment in UV DTF technology. Comprehensive training not only boosts operational efficiency but also fosters a culture of innovation, ensuring that businesses are prepared to enhance their services while staying competitive in an increasingly customized and eco-friendly market.

Frequently Asked Questions

What is UV DTF technology and how does it enhance custom printing?

UV DTF technology, or UV Direct-to-Film technology, merges the precision of UV printing with the versatility of DTF approaches. This innovative printing method enables high-resolution images to be applied onto diverse substrates such as textiles, ceramics, and plastics, greatly enhancing the quality and customization possibilities of custom printing services.

What are the environmental benefits of using UV DTF printing technology?

UV DTF printing utilizes eco-friendly inks that are free from volatile organic compounds (VOCs), significantly reducing air pollution compared to traditional inks. Additionally, advancements in UV curing technologies contribute to lower energy consumption, making this printing technology a sustainable choice for businesses focused on eco-friendly printing practices.

How does UV DTF technology compare to traditional printing methods?

Compared to traditional printing methods, UV DTF technology offers greater versatility in material compatibility and enhanced detail reproduction. It enables the printing of complex designs with vibrant colors on a wider range of substrates, making it ideal for custom printing needs and applications across various industries.

What advancements in curing technology are integral to UV DTF printing?

The integration of UV LED curing technology in UV DTF printing marks a significant advancement, enabling faster production speeds without compromising print quality. This technology allows for efficient operations, meeting high-demand printing needs while ensuring sustainable practices through reduced energy consumption.

What market trends are influencing the growth of UV DTF technology?

The growing consumer demand for personalized and unique products is driving the market growth for UV DTF technology. As businesses seek to offer customized items, the adoption of advanced printing technologies like UV DTF becomes essential to stay competitive and cater to shifting consumer preferences.

How can businesses effectively train their staff on UV DTF technology?

Investing in educational resources and training programs is crucial for businesses adopting UV DTF technology. Comprehensive training initiatives can enhance employees’ understanding of the printing process, improve operational efficiency, and maximize the benefits of this innovative printing technology.

| Key Feature | Description |

|---|---|

| Versatility | Can print on a wide range of substrates including textiles, ceramics, metals, and plastics. |

| High-Quality Prints | Offers excellent detail and vibrant color reproduction, suitable for complex designs. |

| Eco-Friendly | Utilizes eco-friendly inks and lower energy consumption, reducing environmental impact. |

| Technological Innovations | Adopts UV LED curing technology for faster production without sacrificing quality. |

| Market Growth | Growing demand for customizable products driving the market for UV DTF printing. |

| Education and Training | Increasing initiatives aimed at training for businesses to maximize efficiency in UV DTF technology. |

Summary

UV DTF technology represents a cutting-edge advancement in custom printing, forging a path toward innovative, high-quality manufacturing. By embracing the versatility and eco-friendliness of UV DTF printing, businesses can not only meet the growing demand for customized products but also enhance their sustainability practices. This technology’s ability to adapt to various substrates while maintaining exceptional detail and color accuracy makes it ideal for a range of applications. Furthermore, as technological innovations continue to reshape the landscape, companies investing in UV DTF technology will be well-positioned to thrive in an increasingly competitive market, ensuring they meet consumer expectations for personalization and quality.