UV DTF Technology: Revolutionizing Custom Apparel Printing

In the dynamic realm of custom apparel printing, UV DTF (Direct-to-Film) technology is emerging as a transformative force. This cutting-edge eco-friendly printing technology harnesses ultraviolet light to cure inks, enabling the production of durable, high-quality garment printing with exceptional detail and brightness. By streamlining the printing process, UV DTF offers a myriad of benefits for businesses, including increased efficiency, reduced costs, and improved sustainability. As we explore the advantages of UV DTF, we will also uncover how this innovative approach can elevate your brand and meet the demands of a discerning market. With its potential to democratize high-quality custom apparel, UV DTF is setting a new standard in the industry.

Known for its versatility, UV DTF technology, or direct-to-film printing, is fundamentally changing how custom apparel is produced. This modern technique utilizes advanced UV curing processes that ensure vibrant colors and intricate designs are flawlessly transferred onto a variety of fabrics. By adopting such an innovative method, businesses can not only improve the overall quality of their products but also gain significant operational efficiencies. The benefits of utilizing eco-friendly printing technology resonate well with today’s environmentally-conscious consumers, making it a compelling choice for those in the fashion and merchandise sectors. As we delve deeper into direct-to-film printing, we will uncover the myriad opportunities that lie ahead for businesses willing to embrace this game-changing technology.

Understanding UV DTF Technology’s Functionality

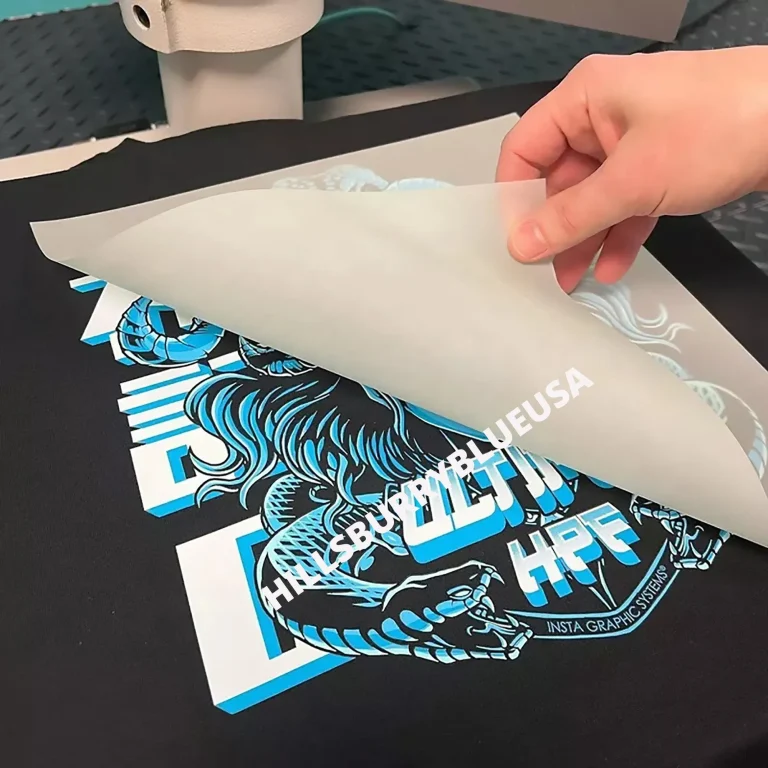

UV DTF technology, or Direct-to-Film printing, stands out in the custom apparel sector for its innovative approach to ink application. By utilizing ultraviolet light, it cures the ink onto a specialized film, which is then transferred onto various fabric materials. This process eliminates the need for screens and lengthy preparation, allowing businesses to respond to custom requests more rapidly than traditional methods. Consequently, this leads to shorter production runs without sacrificing quality, a major advantage in a market where speed and accuracy are paramount.

Moreover, the versatility of UV DTF technology is remarkable. It can be used on a range of fabrics, from cotton to polyester, leather, and even non-fabric materials like vinyl or hard surfaces. This capability not only broadens the types of products available for custom printing but also enables businesses to target diverse markets effectively. The ability to print intricate designs with precision means that companies can cater to the increasing demand for unique and personalized apparel without investing in multiple types of printing technology.

The Unmatched Benefits of UV DTF in Custom Apparel Printing

The benefits of UV DTF technology in custom apparel are profound and multi-faceted. One of the foremost advantages is the technology’s capacity for high-quality garment printing. The crispness of image resolution and the vibrancy of colors make every piece look professionally crafted, setting brands apart in a competitive marketplace. This quality not only attracts more customers but also ensures that they receive products that meet their expectations, thus enhancing customer loyalty and repeat business.

Another noteworthy benefit is sustainability. UV DTF technology promotes an eco-friendly printing approach by reducing ink wastage and utilizing less water compared to traditional methods. The development of less harmful, low-emission inks aligns with the growing consumer push for sustainable practices in manufacturing. In a world where consumers are becoming increasingly conscious of their purchasing choices, businesses that embrace UV DTF technology can proudly market their products as environmentally friendly, thereby reaching a larger audience and fostering brand loyalty.

Speed and Efficiency: The Game-Changer in Apparel Production

When it comes to production efficiency, UV DTF technology redefines what is possible in custom apparel. The traditional printing process often involves numerous steps, including screen creation, color matching, and setup time, which can considerably delay order fulfillment. In contrast, UV DTF simplifies these stages significantly. With its direct application method, designs can be printed and transferred in a fraction of the time, enabling businesses to turn around orders swiftly and meet consumer demands promptly.

This increase in operational speed not only enhances productivity but also supports companies in managing larger volumes of orders. As customer expectations rise and the industry moves towards just-in-time delivery, businesses equipped with UV DTF capabilities can confidently compete, even against larger entities with more extensive resources. Furthermore, the speed without compromising on quality appeals to various market segments, ensuring that brands remain relevant and attractive to their target customers.

Cost-Effectiveness of UV DTF Technology

In addition to efficiency, UV DTF technology brings significant cost advantages suitable for businesses of all sizes. By streamlining production processes and reducing material waste — particularly for short-run custom orders — it allows companies to minimize their operational expenses. The affordability of printed films further contributes, making it a lucrative option for businesses looking to manage their costs effectively while still producing high-quality products.

Moreover, the flexibility UV DTF technology offers means that even smaller businesses or startups can affordably enter the custom apparel market. Without needing to invest heavily in multiple printing methods, they can utilize UV DTF for diverse applications, enhancing their offerings without extensive financial risk. This competitive pricing structure empowers emerging brands to challenge established players, fostering innovation and diversity in the apparel market.

Ensuring Exceptional Durability with UV DTF Prints

Durability is a crucial aspect of any apparel product, and UV DTF technology excels in this regard. The UV curing process ensures that prints are not only vibrant but also resilient against fading, scratching, and damage from washing. This quality assurance translates into garments that maintain their aesthetics over time, which is a vital consideration when consumers decide on their purchases. Brands that prioritize quality and durability not only satisfy existing customers but also attract new ones seeking long-lasting products.

With consumers becoming more discerning regarding their purchasing choices, offering papers that withstand the test of time can significantly influence purchasing decisions. Thus, UV DTF technology aids brands in building a strong reputation for quality, leading to positive reviews, fewer returns, and a loyal customer base. In a market where durability can be a selling point, this reliance on robust printing methods becomes a competitive advantage.

Exploring Sustainable Practices in UV DTF Printing

As sustainability becomes increasingly significant, businesses must adopt practices that resonate with eco-conscious consumers. UV DTF technology addresses this trend by utilizing eco-friendly inks and processes that minimize environmental impact. The reduced use of water and energy compared to traditional printing methods aligns UV DTF with current environmental considerations, making it an attractive option for brands looking to enhance their sustainability credentials.

Additionally, eco-friendly printing technologies not only appeal to consumers but can also lead to financial benefits. By lowering waste and utilizing sustainable processes, brands can streamline their operations and potentially reduce costs. This appeal to both environmental responsibility and economic efficiency positions UV DTF technology as a frontrunner in the custom printing space, providing brands with tools to cultivate a conscientious image while enhancing their bottom line.

Frequently Asked Questions

What are the advantages of using UV DTF technology in custom apparel printing?

UV DTF technology offers several advantages in custom apparel printing, including superior print quality with vibrant colors, increased production efficiency, cost-effectiveness, exceptional durability against fading and wear, versatile applications on various materials, and eco-friendly printing options. These benefits improve brand image and customer satisfaction.

How does UV DTF technology enhance the quality of high-quality garment printing?

UV DTF technology enhances high-quality garment printing by utilizing ultraviolet light to cure inks on specialized films, resulting in high-resolution prints with intricate designs that stand out. This method often surpasses traditional printing techniques, appealing to customers who desire unique, visually striking apparel.

What is the environmental impact of UV DTF technology compared to other printing methods?

UV DTF technology employs eco-friendly inks and processes, reducing material waste and promoting sustainable practices in custom apparel printing. This makes it a greener alternative to traditional printing methods, appealing to environmentally-conscious consumers and helping brands build a responsible image.

Can UV DTF technology be used for printing on materials other than clothing?

Yes, UV DTF technology is incredibly versatile and can be used for printing on various materials beyond clothing, including leather, bags, and home decor items. This expands business opportunities in the custom printing sector, allowing companies to cater to diverse customer needs.

What are the initial costs associated with adopting UV DTF technology for custom apparel businesses?

The initial costs of adopting UV DTF technology include investments in specialized equipment and training for employees. While these upfront expenditures can be substantial, the long-term benefits, including increased profitability and operational efficiency, often outweigh the initial investment.

How does UV DTF technology improve turnaround times for custom apparel orders?

UV DTF technology streamlines the production process by eliminating extensive setup and preparation stages required by traditional printing methods. This leads to faster turnaround times for custom apparel orders, enabling businesses to meet customer demands promptly and enhance overall satisfaction.

| Key Point | Description |

|---|---|

| UV DTF Technology Overview | Utilizes UV light to cure ink on specialized film for durable prints. |

| Superior Print Quality | Produces vibrant, high-resolution prints that surpass traditional methods. |

| Increased Efficiency | Streamlines production with faster turnaround times and reduced setup. |

| Cost-Effectiveness | Reduces material waste and setup costs, enhancing profitability. |

| Exceptional Durability | UV-cured prints resist fading and scratching, leading to higher customer satisfaction. |

| Versatile Applications | Applicable on various fabrics and materials beyond clothing. |

| Sustainable Printing Options | Incorporates eco-friendly inks and processes. |

| Market Impact | Enables small businesses to compete by offering unique designs. |

| Challenges | Requires initial investment and training for businesses. |

Summary

UV DTF Technology is revolutionizing the custom apparel industry by providing an innovative printing solution that enhances quality, efficiency, and sustainability. With its ability to create high-resolution prints quickly and cost-effectively, businesses can meet customer demands while reducing waste and promoting eco-friendliness. This technology not only supports the development of durable and versatile products but also empowers smaller enterprises to thrive in a competitive market. As UV DTF technology continues to evolve, it will set new standards for excellence in the art of custom apparel printing.