UV DTF Printing: Tips for Creating Stunning Visuals

UV DTF printing stands at the forefront of modern printing techniques, revolutionizing how businesses create eye-catching visuals. By merging UV printing technology with Direct to Film applications, this innovative approach allows for high-quality prints on a wide range of materials, making it an ideal choice for various industries. Not only does UV DTF printing produce vibrant and long-lasting images, but it also empowers companies to utilize eco-friendly inks, aligning with the growing trend towards sustainability. Additionally, with the right material selection, businesses can achieve stunning outputs that capture attention and engage customers. As we delve into the world of UV DTF printing, expect insightful tips and tricks that will help you elevate your printing results beyond the ordinary.

In the realm of printing, UV DTF (Direct to Film) technology is making waves by offering versatile solutions that cater to a variety of businesses seeking striking visual presentations. This method harnesses the benefits of ultraviolet printing while expanding the options available for print applications, promising high-quality results and durability. Employing this advanced printing technique enables businesses to achieve intricate designs with vivid colors and reliable longevity—attributes that are increasingly sought after by consumers today. Furthermore, the choice of sustainable water-based inks in this process reflects a wider shift towards environmentally responsible practices within the industry. By considering alternative terms such as Direct to Film UV printing, businesses can better understand the significance of material selection and optimized techniques to enhance their creative output.

Understanding the Process of UV DTF Printing

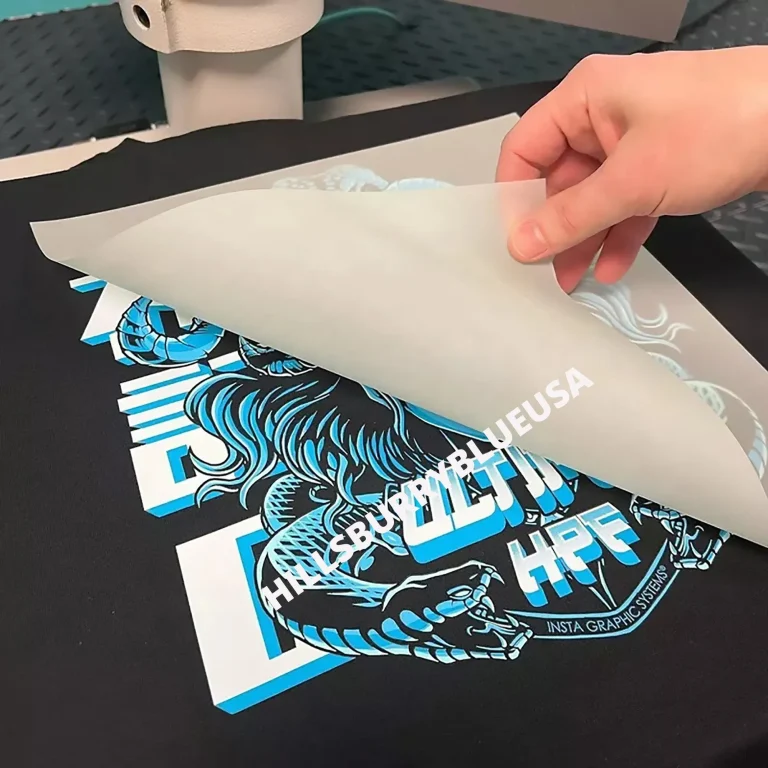

UV DTF printing is a sophisticated combination of Direct to Film (DTF) printing and UV technology, enabling vivid color reproduction on various materials. This model offers unparalleled versatility, allowing businesses to print on textiles, plastics, and even wood. By leveraging these advanced techniques, companies can achieve high-quality prints that are both durable and eye-catching. Many graphic designers and manufacturers are turning to UV DTF printing to create custom apparel and promotional materials that stand out in a competitive marketplace.

Moreover, this technology is characterized by its quick curing process, resulting in prints that are ready for handling almost immediately. The application of UV light during the curing phase ensures that inks dry rapidly, leading to reduced production times. With the ability to print complex designs and vibrant colors directly onto substrates, UV DTF printing is revolutionizing how businesses approach branding and personalized products.

Material Selection for Optimal UV DTF Results

Choosing the right materials is crucial for achieving stunning results with UV DTF printing. The compatibility of the film with UV inks significantly impacts the overall print quality, so selecting high-quality films such as clear PET is highly recommended. These materials not only enhance color vibrancy but also ensure that prints adhere well to various surfaces. Understanding material properties helps in optimizing the printing process and achieving the desired results.

Additionally, the selection of substrates plays a vital role in the visual outcome of UV DTF prints. Substrates with smooth surfaces provide a better foundation for detailed and intricate designs, while textured surfaces can create unique effects. Businesses should conduct thorough tests and experiments with various materials to find the perfect match for their intended designs, which can ultimately lead to eye-catching products.

Achieving High-Quality Prints with UV DTF Techniques

For businesses aiming for high-quality outputs, mastering print settings is essential. Proper calibration of the printer’s UV settings is critical in minimizing common issues like ink bleeding and incomplete curing. Factors such as temperature, UV intensity, and curing duration must be fine-tuned to perfection for the best results. Regular maintenance, including firmware updates and cleaning routines, can enhance printing reliability and quality.

Before embarking on a print run, ensuring that artwork is high resolution and properly formatted is necessary for flawless results. Utilizing vector graphics not only preserves clarity across various sizes but also guarantees that intricate details remain intact. Pre-setting colors in CMYK format allows for greater accuracy in color simulation, which is essential for achieving vibrant output in UV DTF printing.

Maximizing the Curing Process in UV DTF Printing

The curing process is a pivotal step in UV DTF printing that directly influences the durability and appearance of the final product. The utilization of advanced LED UV lights has emerged as a game-changer, enhancing curing efficiency and contributing to a smoother finish. Understanding the specifics of different substrates allows printers to adjust curing times accordingly, ensuring optimal adhesion and longevity of prints.

Experimenting with varying curing conditions can also yield different aesthetic effects, enabling designers to create unique finishes that differentiate their products. By carefully monitoring the curing process, printmakers can achieve vibrant colors that not only catch the eye but also maintain their brightness over time, establishing brand reputation and customer satisfaction.

Regular Maintenance for Long-Term Success in UV DTF Printing

Collectively, equipment maintenance is fundamental for sustaining success in UV DTF printing operations. Routine checks, including cleaning the print heads and checking UV light functionality, ensure that printers operate at peak performance, minimizing downtime and costly repairs. Establishing a scheduled maintenance protocol enhances the longevity of printing equipment and guarantees consistency in print quality.

Moreover, keeping abreast of technological advancements is critical for maintaining a competitive edge in the market. Engaging with industry forums and participating in workshops can provide valuable insights into best practices, new tools, and techniques that advanced printers can integrate into their processes.

Embracing Innovation: Trends in UV DTF Printing

As technology advances, the UV DTF printing field also sees remarkable innovations that redefine industry standards. One notable trend is the increasing use of eco-friendly inks, which address sustainability concerns while maintaining high print quality. Water-based UV inks, for instance, are gaining traction, enabling businesses to produce vibrant prints while reducing their environmental footprint.

These innovations not only appeal to environmentally conscious consumers but also enhance the brand image of companies committed to sustainable practices. Adopting these forward-thinking methodologies can position businesses as leaders in a market that increasingly values ecological responsibility.

Frequently Asked Questions

What is UV DTF printing and how does it work?

UV DTF printing, or UV Direct To Film printing, is a technique that combines UV printing technology with direct-to-film applications to create vibrant, long-lasting prints. This method allows for printing on various materials, from textiles to promotional items, ensuring high-quality results with intricate designs and vivid colors.

What types of materials are ideal for UV DTF printing?

When it comes to material selection for UV DTF printing, clear PET films are highly recommended. They enhance color vibrancy and ensure strong adherence to multiple substrates. Understanding the properties of materials is crucial for achieving high-quality prints and optimizing your printing process.

How can printer settings affect UV DTF printing quality?

Printer settings are critical in UV DTF printing quality. Proper calibration of UV intensity, temperature, and curing time significantly influences the outcome. Regularly updating your printer’s firmware and adjusting settings can prevent issues such as ink bleeding and incomplete curing, leading to improved print quality.

What are the best practices for preparing artwork for UV DTF printing?

High-resolution artwork is essential for UV DTF printing. Using vector graphics helps retain clarity, while pre-setting colors in CMYK provides a more accurate color representation. Ensuring your artwork is formatted correctly before printing can save time and resources, enhancing overall print quality.

How does curing impact the final print in UV DTF technology?

Curing is vital in UV DTF technology as it determines the durability and appearance of the final product. Utilizing LED UV lights can enhance curing efficiency, leading to smoother finishes and better print longevity. Experimenting with curing times based on the material can optimize results and improve overall print quality.

What innovations are emerging in UV DTF printing for sustainability?

Recent advancements in UV DTF printing technology include the development of eco-friendly inks, such as water-based UV inks, which address sustainability concerns without sacrificing print quality. These innovations make the printing process more environmentally responsible, reflecting a growing trend toward sustainable printing practices.

| Tip | Description |

|---|---|

| Material Selection | Choose compatible films like clear PET for vibrant results and excellent adherence to substrates. |

| Printer Settings | Calibrate UV printer settings (temperature, intensity, curing time) for optimal results. |

| Artwork Preparation | Use high-resolution vector graphics and set colors in CMYK for accurate prints. |

| Optimizing Curing Process | Experiment with LED UV lights and curing times to enhance durability and finish. |

| Regular Maintenance of Equipment | Routine cleaning and maintenance of equipment to prevent clogging and downtime issues. |

| Experimentation and Creativity | Explore different ink layers and textures for unique effects in your prints. |

Summary

UV DTF Printing is a revolutionary technique that allows businesses to produce stunning visuals with vibrant colors and intricate details. By adopting essential tips such as selecting the right materials, optimizing printer settings, and preparing high-quality artwork, you can tremendously enhance your printing outcomes. Moreover, with a focus on equipment maintenance and creative experimentation, you can achieve long-lasting, eye-catching prints that stand out in the competitive market. Staying updated on the latest advancements in UV DTF technology, including eco-friendly inks, will further elevate your printing capabilities and help maintain a sustainable practice. Embrace the future of UV DTF Printing to unlock innovative possibilities for your business.