UV DTF Printing: A Comparison with Other Printing Techniques

In the dynamic world of printing, UV DTF printing stands out as a revolutionary technique that combines the benefits of ultraviolet (UV) technology with the advantages of direct-to-film (DTF) methods. Offering vibrant colors and exceptional durability, this innovative printing method has quickly gained traction among businesses seeking high-quality results across various substrates. Unlike traditional methods such as silkscreen and sublimation printing, UV DTF printing enables a broader range of applications, making it an ideal choice for those looking to print on challenging materials like metals and wood. Its eco-solvent printing counterparts often fall short in curing times and versatility, but UV DTF excels by delivering faster results without compromising on quality. As we explore the details of UV DTF printing, we will highlight its key distinctions and advantages over other popular printing techniques.

When it comes to modern printing solutions, the term “Direct to Film (DTF) printing” has garnered attention alongside its innovative counterpart, “UV Direct to Film printing.” This advanced method utilizes ultraviolet curing, allowing for brighter colors and sharper images compared to traditional approaches such as silkscreen and sublimation printing. As industries continuously seek efficient and versatile solutions, the relevance of eco-solvent and other printing technologies prompts a reassessment of their capabilities against this newer UV-enhanced option. Incorporating the best features of traditional printing while mitigating their constraints, UV DTF presents a compelling alternative that resonates well with contemporary demands for quality and adaptability.

Understanding UV DTF Printing: The Basics

UV DTF printing, or ultraviolet direct-to-film printing, represents a significant leap forward in printing technology. This technique takes advantage of UV inks, which are cured instantly using ultraviolet light, allowing for the creation of sharp, vivid prints on a wide range of materials. Unlike some other methods, such as sublimation or silkscreen printing, UV DTF does not require extensive setup or handling of the substrate prior to printing; this simplicity makes it a popular choice among print service providers aiming for efficiency.

This technology excels in versatility, capable of printing on non-traditional surfaces such as metal, wood, and glass. It caters to both rigid and flexible substrates, thereby expanding the potential applications greatly. With the increasing demand for intricate designs and small-batch production, UV DTF printing offers the adaptability needed to meet modern market requirements, making it a frontrunner among other techniques like eco-solvent and sublimation printing.

Benefits of UV DTF Printing Over Traditional Techniques

One of the standout advantages of UV DTF printing is its efficiency compared to traditional methods, such as silkscreen and eco-solvent printing. While silkscreen printing excels in producing large quantities of vivid colored prints, it can be laborious and time-consuming, especially when adjustments or new designs are needed. UV DTF, on the other hand, allows for rapid adjustments without laborious setups, meaning designs can be modified or changed on-the-fly, saving valuable time during production.

Additionally, UV DTF technology does away with the limitations faced by many traditional printing methods, such as the restriction to specific materials. Unlike sublimation printing which is confined to light-colored polyester fabrics, UV DTF can produce quality prints on dark fabrics, hard materials, and other challenging surfaces. This broadening of material compatibility not only enhances practicality but opens doors to creative possibilities that were previously constrained by traditional approaches.

Comparative Analysis: UV DTF vs Sublimation Printing

Sublimation printing is highly regarded for its ability to produce high-quality images that are vibrant and permanent on polyester-based fabrics. However, it falls short when it comes to material limitations, as it can only be used on light fabrics and is not meant for hard substrates. In contrast, UV DTF printing provides a much wider scope, allowing for the exploration of diverse materials including metals and plastics. This makes UV DTF a more flexible solution for businesses looking to cater to varied customer preferences.

Moreover, the durability of prints created through UV DTF technology is often superior to those produced through sublimation methods. The UV inks used in DTF printing create a surface that is highly resistant to wear and fading, making it an ideal choice for items that are frequently handled or exposed to the elements. This advantage positions UV DTF printing as a preferred choice for products that require longevity, further highlighting the benefits over sublimation techniques.

The Role of UV DTF Printing in Custom Merchandise

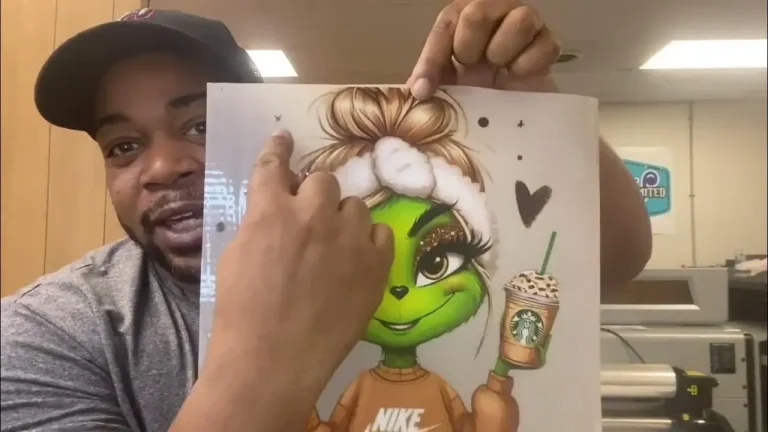

Custom merchandise has seen a surge in popularity, and UV DTF printing plays a pivotal role in this trend. By enabling printing on varied materials, it allows businesses to offer a broad array of customized products, from promotional items to one-off bespoke creations. This adaptability, combined with the ability to produce high-quality, vibrant imagery quickly and efficiently, attracts both consumers and vendors searching for personalized solutions.

Additionally, the quick turnaround times associated with UV DTF printing are crucial in the competitive nature of the custom merchandise market. With the growing trend of on-demand printing, businesses can fulfill customer demands faster than ever, ensuring they remain ahead of the curve. This translates to increased customer satisfaction and loyalty, making UV DTF an essential tool for enterprises looking to thrive in this dynamic environment.

Implementing UV DTF in Business Operations

Integrating UV DTF printing into a business’s operations can transform production capabilities, offering a competitive edge in a saturated marketplace. By utilizing this technology, businesses can increase their output while maintaining high-quality standards. The instant curing capabilities mean less time is spent waiting for prints to dry, allowing for streamlined workflows and the capacity to fulfill orders quickly.

Moreover, with the growing demand for customization, the transition to UV DTF printing can significantly enhance product offerings. By adopting this technology, businesses can expand their services to include unique designs and personalized items without the hassle of extensive setup procedures typical of other printing methods. This not only elevates operational efficiency but also aligns with contemporary market trends focused on customization.

Future Trends in UV DTF Printing

The future of UV DTF printing looks promising, with ongoing advancements poised to further enhance its capabilities. Innovations in ink technology and printhead design are expected to yield even better adhesion and faster curing times, increasing the efficiency and versatility of printing processes. As businesses aim for greater sustainability in their printing practices, developments in eco-friendly ink formulations also promise to keep pace with environmental considerations.

Moreover, as consumer preferences continue to shift toward custom and on-demand solutions, the demand for UV DTF printing is likely to rise. Industries such as fashion, home décor, and promotional products are increasingly relying on this technology to meet the requirements of modern consumers, creating a robust market for future growth. Staying on top of industry trends and technology developments will ensure businesses leveraging UV DTF remain competitive and innovative in their offerings.

Frequently Asked Questions

What is UV DTF printing and how does it differ from traditional DTF printing?

UV DTF printing stands for UV Direct to Film printing, which combines the advantages of UV printing with direct-to-film technology. Unlike traditional DTF printing that is primarily suited for fabrics, UV DTF printing excels in creating vibrant, durable images on a wide variety of surfaces, including hard materials like metals and wood, by using inks cured instantly by UV light.

What are the benefits of using UV DTF printing compared to sublimation printing?

UV DTF printing offers several advantages over sublimation printing, particularly its versatility in printing on both light and dark substrates without material restrictions. While sublimation is limited to polyester and light colors, UV DTF can produce high-quality images on a broader range of materials, making it an ideal choice for diverse applications.

How does UV DTF printing perform in terms of speed compared to silkscreen printing?

UV DTF printing is generally faster than traditional silkscreen printing due to its ability to handle intricate designs without the need for extensive setup. While silkscreen requires time-consuming stencil creation, UV DTF allows for immediate adjustments and quicker production times, enhancing overall efficiency.

In what applications is UV DTF printing most effective compared to eco-solvent printing?

UV DTF printing is particularly effective in producing high-quality prints on a variety of surfaces, including rigid materials, making it suitable for custom signage, promotional materials, and merchandise. In contrast, eco-solvent printing, while producing vibrant outputs, is often slower and primarily used for flexible substrates, which limits its application scope.

Can UV DTF printing be used for outdoor applications just like traditional UV printing?

Yes, UV DTF printing is suitable for outdoor applications, similar to traditional UV printing. The inks used in UV DTF printing are highly durable and resistant to fading, making them ideal for products that will be exposed to sunlight and environmental elements, ensuring long-lasting quality.

What advancements are currently driving the growth of UV DTF printing technologies?

Recent advancements in UV DTF printing technologies include improved ink formulations for better adhesion and faster curing times. Additionally, innovations in printhead technology enhance reliability and user-friendliness, making UV DTF systems more accessible and efficient for businesses looking to offer customized and on-demand printing solutions.

| Comparison Criteria | Traditional Silkscreen | Non-UV DTF Printing | Sublimation Printing | Eco-Solvent Printing |

|---|---|---|---|---|

| Pros | Vivid colors; efficient for long runs | Vibrant colors; effective on fabrics | Permanent visuals on polyester fabrics | Vibrant outputs suitable for outdoor use |

| Cons | Labor-intensive and slow for design changes | Limited on hard surfaces; additional steps needed | Restricted to light-colored substrates | Slower with longer curing times |

| Key Point | Faster intricate design changes without new stencils | Versatile on hard substrates; broad application range | Wider color application and material use | Quicker processing, reducing production time |

Summary

UV DTF Printing stands out in the printing industry due to its remarkable capabilities and efficiency. This innovative technique allows for the creation of vibrant images on various surfaces, demonstrating exceptional versatility that surpasses many traditional printing methods. With the ability to print seamlessly on challenging materials like metals and woods, UV DTF printing provides businesses with the flexibility to offer diverse products. Continued advancements in technology bolster these benefits, further solidifying UV DTF printing’s position as a crucial tool for customization and rapid production in today’s marketplace.