UV DTF Gangheet: What Businesses Should Know Today

UV DTF Gangheet is redefining the landscape of custom printing technology by merging unparalleled print quality with innovative techniques. This breakthrough method utilizes UV DTF (Direct to Film) printing, allowing businesses to achieve vibrant, durable prints suitable for a vast array of materials. As the market trends in printing continue to evolve, companies that adopt UV DTF Gangheet are witnessing remarkable benefits, including enhanced customization options and efficiency in production. Furthermore, with the growing consumer demand for personalized products, understanding the nuances of UV DTF tech can be a significant competitive advantage. Innovations in printing processes such as these drive the transformation of the industry, pushing the boundaries of what’s possible in print design and application.

Delving into the realm of UV DTF printing, also known as Direct to Film printing, reveals how Gangheet—referring to specialized techniques within this domain—can drastically improve business outcomes. As markets shift toward personalized solutions, custom printing methodologies are gaining traction, highlighting the need for businesses to stay abreast of innovations in printing. The adoption of UV DTF technologies opens the door to numerous benefits, such as a wider variety of substrates and exceptional print clarity. Moreover, tracking market trends in printing showcases the increasing demand for unique and bespoke products, making this technology essential for those looking to thrive in a competitive environment. By embracing these advancements, companies can enhance their operational efficiency and enrich their product offerings.

Exploring the Advantages of UV DTF Gangheet in Modern Printing

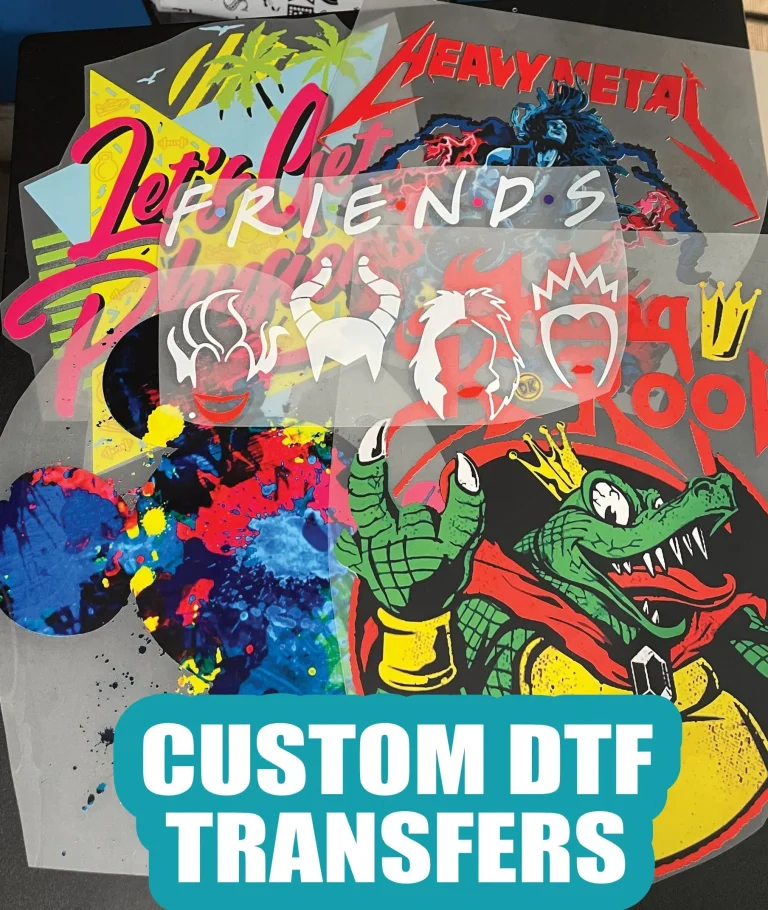

UV DTF Gangheet brings forth a myriad of benefits that are essential for businesses aiming to thrive in today’s competitive printing landscape. One of the most significant advantages is its unrivaled versatility. Unlike conventional printing methods, UV DTF allows for high-definition prints on almost any substrate—be it fabric, plastic, wood, or metal. This flexibility makes it a prime choice for various industries, from fashion to promotional merchandise, enabling businesses to cater to diverse client needs without being limited by material constraints.

Another key benefit of the UV DTF Gangheet process is its exceptional print quality. The fusion of vibrant colors and intricate detail results in stunning visual outputs that enhance product appeal. With innovations in ink technology, UV DTF prints exhibit superior durability and resistance to fading, contributing to long-lasting customer satisfaction. This is especially crucial in competitive markets where brand loyalty is directly connected to product quality. Ultimately, companies leveraging UV DTF Gangheet can enhance their market presence through eye-catching designs that stand the test of time.

Market Trends Shaping UV DTF Printing

The UV DTF printing market is currently witnessing transformative trends that businesses need to be aware of. One prominent trend is the growing demand for customization. Consumers are increasingly seeking personalized products tailored to their specific tastes, which has placed UV DTF technology at the forefront of meeting these market needs. Businesses are capitalizing on this shift by offering bespoke items, from uniquely designed apparel to custom promotional products, thereby solidifying customer relationships and driving sales.

Additionally, the trend towards on-demand printing is reshaping manufacturing and distribution practices. Companies are leaning toward UV DTF printing to reduce inventory costs while still providing a wide array of product options. This technology allows for the production of items only as they are ordered, minimizing waste and maximizing operational efficiency. As market dynamics continue to evolve, businesses embracing these trends with UV DTF printing can position themselves as leading innovators in their fields.

The Role of Innovations in UV DTF Printing

Innovations play a crucial role in the development and enhancement of UV DTF printing technology. Continuous advancements in printheads, ink formulations, and curing methods are contributing to improved efficiency and cost-effectiveness. These innovations not only empower print service providers to increase production speeds but also enhance the quality and adaptability of the output. Keeping abreast of these technological innovations is essential for businesses aiming to maintain a competitive edge in the evolving landscape.

Furthermore, the exploration of innovative materials is opening new avenues for UV DTF printing. Research into advanced inks and substrates is not only enhancing the durability of prints but also expanding the range of applications for this technology. Businesses that invest in the latest innovations stand to benefit from a broader product offering, allowing for unique designs and creative possibilities that were previously unattainable. Tapping into these emerging materials and techniques can significantly elevate the quality and scope of UV DTF printing services.

Overcoming Challenges in Adopting UV DTF Technology

Despite its benefits, the adoption of UV DTF technology is not without challenges, particularly regarding initial investment costs. Companies looking to implement UV DTF systems often face substantial upfront expenses for equipment and materials. However, it is essential to consider long-term returns on investment. The potential for increased sales through high-quality, customizable products can ultimately outweigh the initial financial burden, making it a worthwhile investment in the company’s future.

Another challenge is the need for technical expertise to operate and maintain UV DTF equipment effectively. It is crucial for businesses to invest in training for their staff to ensure they are equipped with the skills needed to navigate this technology. Training can lead to improved productivity and higher-quality outputs, which ultimately contributes to customer satisfaction. By addressing these challenges proactively, companies can leverage the full potential of UV DTF printing to enhance their offerings and profitability.

Environmental Benefits of UV DTF Printing

The environmental impact of printing technologies is becoming an increasingly vital consideration for businesses looking to meet consumer demand for sustainability. UV DTF printing stands out as an eco-friendly option, primarily due to its use of modern UV inks that are less harmful than traditional solvent-based alternatives. These inks often emit fewer volatile organic compounds (VOCs) and are more sustainable, making them a responsible choice for businesses aiming to reduce their carbon footprint.

Moreover, UV DTF technology supports on-demand production, which effectively minimizes waste associated with excess inventory. By producing items only as they are ordered, businesses can operate more sustainably, aligning their practices with wider environmental goals. This approach not only attracts environmentally-conscious consumers but also enhances the overall marketability of the products, further solidifying the business’s reputation as an eco-friendly brand.

Future Prospects for UV DTF Printing Technology

The future outlook for UV DTF printing technology is promising, with anticipated advancements set to revolutionize the industry further. As research and development continue, improvements in printing processes, such as faster production speeds and better resource management, are expected to materialize. These enhancements will significantly lower costs, providing businesses with the opportunity to increase output without compromising quality.

In addition, ongoing explorations into new inks and substrates present exciting possibilities for the evolution of UV DTF printing. The introduction of advanced materials and formulations can broaden the scope of applications, enabling businesses to push the boundaries of creative design. As companies adapt to these future developments, they will find new ways to meet customer preferences and differentiate their products in a crowded marketplace. Remaining attentive to these trends will be crucial for businesses aiming for long-term success in UV DTF printing.

Frequently Asked Questions

What are the benefits of UV DTF printing for businesses?

UV DTF printing offers numerous benefits for businesses, including versatility in applications, exceptional print quality, and eco-friendly options. This technology can print on various substrates, ensuring high durability and vibrant colors that enhance customer satisfaction and brand loyalty.

How does UV DTF Gangheet improve custom printing technology?

UV DTF Gangheet refers to the specific techniques used in UV DTF printing. By optimizing these methods, businesses can achieve higher quality outputs and more efficient production processes, ultimately enhancing their custom printing capabilities and meeting consumer demands for unique products.

What market trends are influencing UV DTF printing today?

Current market trends impacting UV DTF printing include the growing demand for customization, a shift towards on-demand printing, and continuous innovations in printing materials and technologies that enable businesses to meet evolving consumer preferences effectively.

Are there any initial investment challenges with UV DTF technology?

Yes, one of the primary challenges when adopting UV DTF technology is the significant initial investment required for the equipment and materials. However, the potential for increased revenue from high-quality, customized products can justify the upfront costs.

What makes UV DTF printing eco-friendly compared to traditional methods?

UV DTF printing utilizes modern UV inks that are generally more environmentally friendly than traditional solvent-based inks. By adopting UV DTF technology, businesses can appeal to environmentally-conscious customers and enhance their sustainability image.

How can businesses stay competitive with advances in UV DTF printing technology?

To remain competitive, businesses should stay updated on innovations in UV DTF printing, such as advancements in ink formulations, printheads, and curing technologies, which can improve the quality, speed, and cost-efficiency of their printing operations.

| Key Point | Description |

|---|---|

| Understanding UV DTF Printing | A technology that merges traditional printing with UV curing processes, allowing high-quality prints on diverse substrates. |

| Benefits of UV DTF Printing | Includes versatility across materials, exceptional print quality, and eco-friendly options. |

| Market Trends | Increasing demand for customization, a shift to on-demand printing, and innovations in materials and technology. |

| Challenges | Initial investment costs, need for technical expertise, and supplier selection impact the adoption of UV DTF. |

| Future Developments | Advancements in printing processes and ongoing research into inks and substrates promise to enhance UV DTF technology. |

Summary

UV DTF Gangheet represents a significant evolution in the printing landscape, providing businesses with a powerful tool to offer personalized and high-quality products. By understanding the innovative techniques involved in UV DTF printing and the wide array of benefits it presents, companies can effectively adapt to market demands. The combination of versatile applications, remarkable print quality, and eco-friendly solutions not only fosters customer satisfaction but also positions businesses strategically in a competitive market. As the technology continues to advance, those who invest in UV DTF Gangheet will likely find themselves leading the charge in custom printing innovation.