UV DTF Gangheet: Revolutionizing Your Printing Business

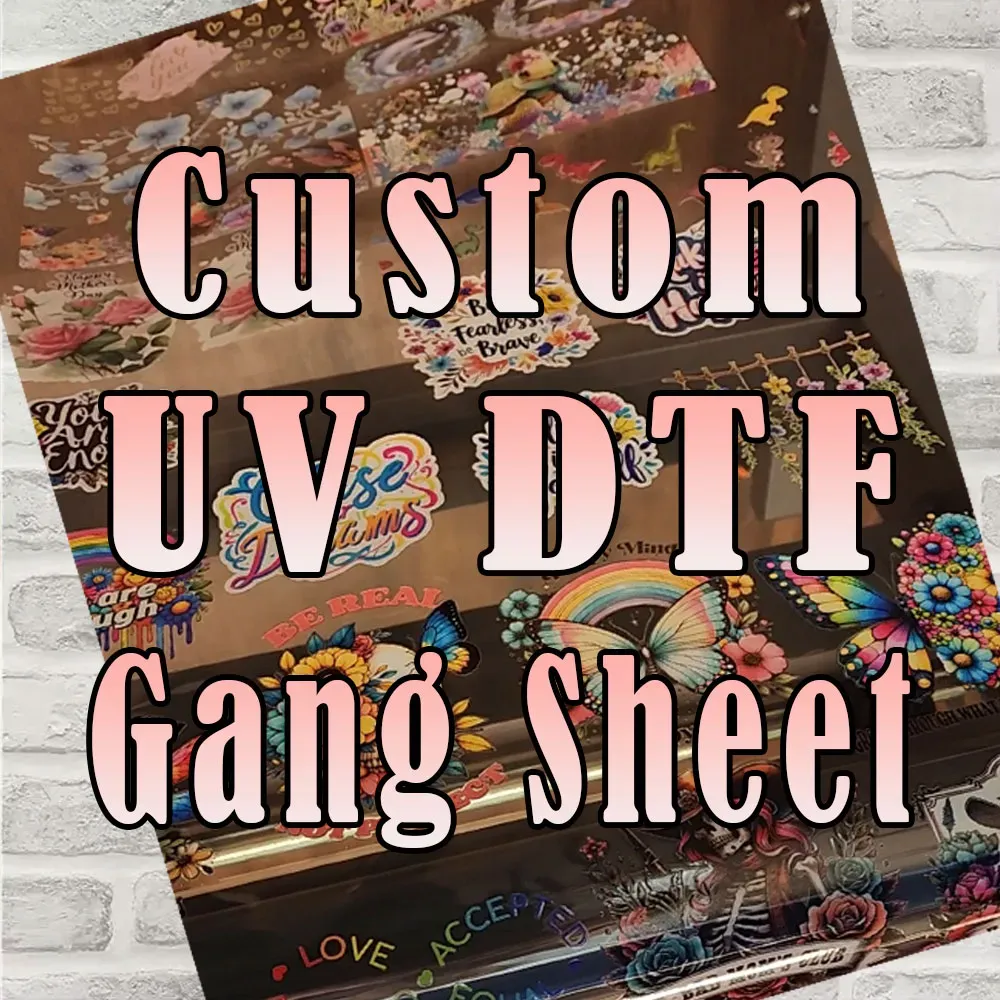

UV DTF gangheet printing is revolutionizing the way businesses approach their printing needs, blending cutting-edge printing technology with efficient production methods. This innovative technique combines ultraviolet (UV) printing with direct-to-film (DTF) processes, effectively allowing multiple designs to be printed on a single sheet—commonly referred to as gang sheets. The result is not only significant cost savings but also high-quality and durable prints that appeal to a diverse clientele. As industries increasingly prioritize sustainable printing solutions, the eco-friendly aspects of UV DTF gangheet are becoming more crucial for companies eager to stay competitive. In this blog, we will delve into the transformative benefits of UV DTF gangheet printing and how it can elevate your printing business to new heights.

As the demand for advanced printing solutions grows, understanding the role of UV DTF technology and gang sheets is essential for modern print businesses. UV DTF refers to a state-of-the-art printing method where vibrant and durable inks are cured using ultraviolet light, while gang sheets facilitate the efficient use of printing materials by accommodating multiple designs in a single production cycle. This combination not only enhances print quality but also maximizes operational efficiency and reduces waste, aligning perfectly with contemporary trends in sustainable printing. Whether you’re catering to small clients or large orders, this innovative approach allows businesses to thrive by offering flexibility and customization in their services. Exploring these alternative terms reveals how UV DTF gangheet technology is defining the future of the printing industry.

The Advantages of UV DTF Printing Technology

UV DTF printing technology stands at the forefront of modern printing solutions, offering a host of advantages that make it an appealing choice for businesses. First and foremost, the vibrant color reproduction and sharp detail achieved through UV inks set this technology apart from traditional methods. The quick curing process, activated by UV light, allows for rapid production without compromising on quality. As a result, businesses can produce high-end products that not only meet but exceed customer expectations, ensuring a competitive edge in today’s saturated market.

Furthermore, the adaptability of UV DTF printing technology enables businesses to explore diverse applications. Whether printing on textiles, plastics, or metals, this technique supports a wide variety of materials, making it ideal for custom projects. Clients today are increasingly seeking unique and personalized solutions; UV DTF enables providers to meet this demand with custom prints that cater to individual tastes. Such versatility not only boosts customer satisfaction but also opens new revenue streams for printing companies.

Boosting Efficiency with Gang Sheets

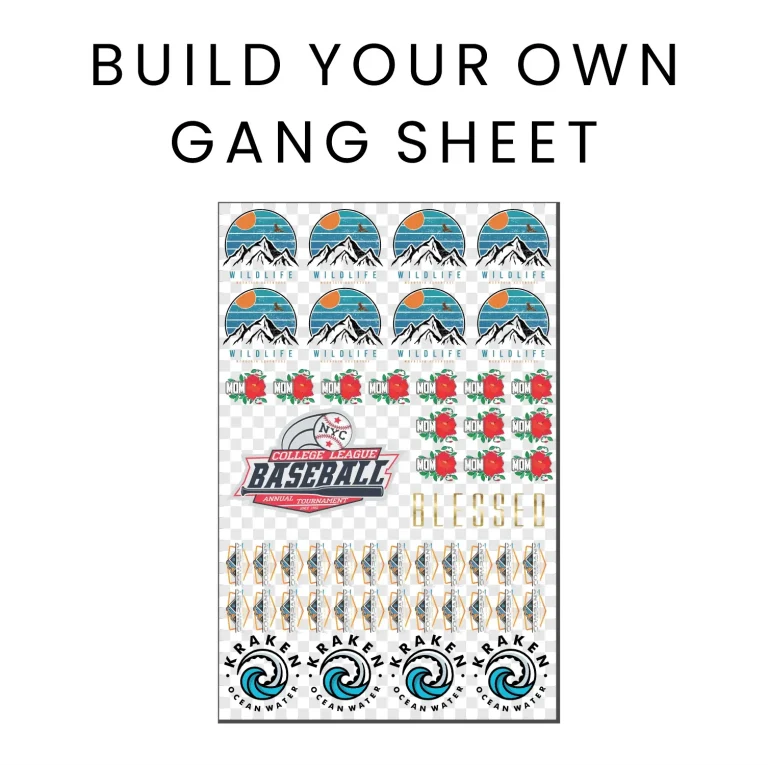

The integration of gang sheets in the UV DTF printing process significantly enhances operational efficiency. Gang sheets allow multiple designs to be printed simultaneously on one large sheet, which optimizes material usage and minimizes waste. This strategy not only reduces costs but also accelerates the production timeline. By consolidating orders from various clients, businesses can streamline their workflow, shorten setup times, and lower labor costs, contributing to overall operational efficiency. As the printing industry evolves, adopting this approach is crucial for staying competitive.

Moreover, gang sheet printing fosters greater adaptability in response to changing market demands. For businesses inundated with small batch orders, combining these into a single production run can be a game-changer. This minimizes downtime and maximizes output, allowing businesses to handle more orders without compromising on quality. As speed and efficiency continue to drive customer satisfaction in the printing sector, the strategic use of gang sheets in UV DTF printing becomes an essential element for success.

Sustainability in UV DTF Printing

In an era where eco-consciousness pervades consumer preferences, sustainability in printing is paramount. UV DTF printing technology promotes environmentally friendly practices by utilizing UV inks that produce fewer volatile organic compounds (VOCs) compared to traditional inks. This not only lessens the environmental impact of printing operations but also positions businesses as proponents of sustainable practices, appealing to a growing demographic of environmentally-aware consumers.

By embracing sustainable printing methods through UV DTF and gang sheets, companies can reduce waste and improve their overall carbon footprint. The capability to print multiple designs on one sheet aligns with waste reduction goals. Businesses that adopt these practices not only contribute to ecological preservation but also gain a marketing edge, showcasing their commitment to sustainability. Such positioning can strengthen brand loyalty and attract new clients who prioritize ethical consumption.

Enhancing Product Customization

Customization is a key trend in today’s market, and UV DTF printing technology supports this demand exceptionally well. The versatility of materials and the capability of producing intricate designs make it an ideal solution for businesses seeking to offer personalized products. Whether for promotional items, custom apparel, or unique gifts, the ability to print vibrant, detailed designs on various substrates allows printing businesses to cater to niche markets and individual client needs effortlessly.

The use of gang sheets further amplifies customization capabilities. By allowing multiple designs to be printed at once, businesses can easily accommodate diverse orders without sacrificing efficiency. This method not only enhances product variety but also ensures quick turnaround times for personalized products, aligning with consumers’ increasing desire for rapid delivery. In a landscape where personalization is becoming the norm, utilizing UV DTF printing with gang sheets can significantly bolster a business’s appeal and profitability.

Speed and Effectiveness in Production

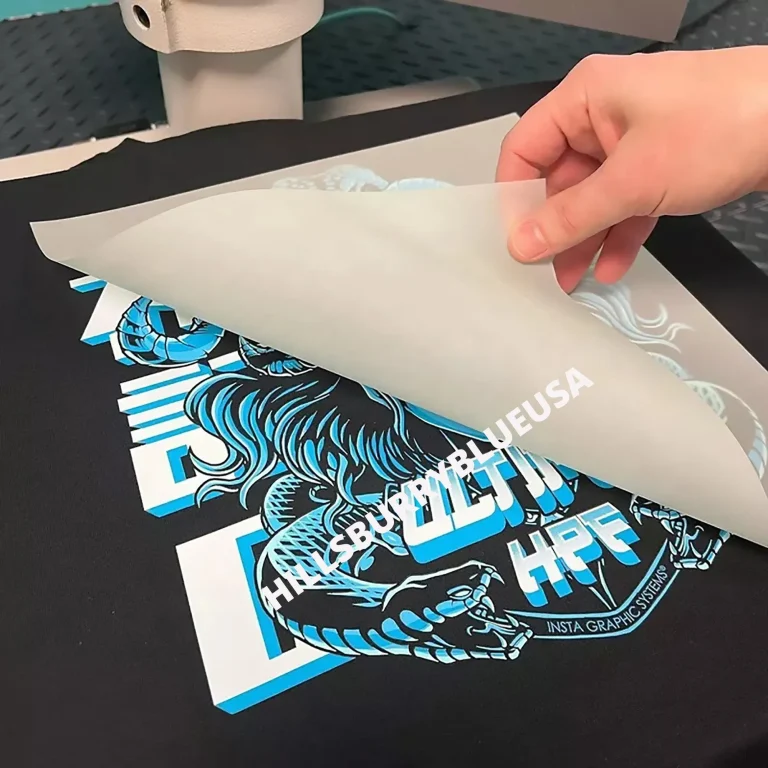

In a competitive printing environment, speed and effectiveness are crucial in meeting client demands. UV DTF printing offers faster drying times compared to traditional methods, significantly reducing production cycle duration. This efficiency is especially beneficial for businesses handling urgent orders or high-volume projects that require quick turnaround. With the ability to rapidly produce high-quality prints, businesses can not only satisfy their clients but also seize opportunities to attract new ones.

Additionally, the combination of gang sheets with UV DTF technology enhances productivity further. By maximizing the use of each sheet, businesses can execute more projects simultaneously, leading to a substantial increase in output. As consumer expectations continue to rise regarding delivery timelines, being able to provide swift and effective solutions can distinguish a business from its competitors, ensuring customer loyalty and repeat business.

Implementing UV DTF Gangheet: A Strategic Choice

Adopting UV DTF gangheet printing is not just a technological upgrade; it’s a strategic move that can lead to significant growth opportunities. Integrating this advanced printing method into your business operations allows you to respond effectively to market demands while enhancing quality and efficiency. This technology enables printing companies to produce stunning visuals on various materials, making it a versatile choice for different industries and applications.

Moreover, the investment in UV DTF gangheet printing aligns with current consumer trends toward sustainability and customization. Businesses that champion innovation and sustainability attract clients who value ethical consumerism. As you consider the future of your printing business, incorporating UV DTF gangheet technology will position you at the forefront of the industry, ready to tackle upcoming challenges while fostering an ethos of excellence and responsibility.

Frequently Asked Questions

What is UV DTF gangheet printing and how does it work?

UV DTF gangheet printing is a modern printing technology combining UV printing with direct-to-film (DTF) techniques. It involves printing vibrant, UV-cured inks onto transfer films, which can then apply designs to various materials like fabric, plastic, and metal. The use of gang sheets allows multiple designs to be printed simultaneously, maximizing material efficiency and reducing waste.

What are the benefits of using UV DTF gangheet for my printing business?

Using UV DTF gangheet printing brings numerous benefits including high-quality, durable prints, versatility across various substrates, efficient production through gang sheets, faster turnaround times, and eco-friendly practices. These advantages allow businesses to enhance customer satisfaction while optimizing operations.

How does UV DTF gangheet printing improve printing efficiency?

UV DTF gangheet printing enhances printing efficiency by allowing multiple designs to be printed on a single sheet. This reduces material waste and setup time, enabling businesses to fulfill diverse customer orders more effectively, minimizing costs while maximizing production flexibility.

In what ways can UV DTF printing contribute to sustainable printing practices?

UV DTF printing contributes to sustainable practices by utilizing eco-friendly UV inks that emit fewer volatile organic compounds (VOCs) compared to traditional inks. This not only helps the environment but also aligns businesses with the growing consumer preference for sustainable products.

Can UV DTF gangheet printing be used on various materials?

Yes, UV DTF gangheet printing is highly versatile and can be used on a wide range of materials including textiles, plastics, wood, glass, and metal. This flexibility allows businesses to cater to different industries and meet diverse customer needs.

Why should I choose UV DTF gangheet printing for fast-turnaround projects?

Choosing UV DTF gangheet printing for fast-turnaround projects ensures faster production cycles due to shorter drying times compared to traditional printing methods. This capability is essential for meeting tight deadlines, such as those for promotional items or custom orders, enhancing overall client satisfaction.

| Key Benefits of UV DTF Gangheet Printing | ||

|---|---|---|

| 1. High Quality and Durability | UV inks provide vibrant colors and sharp details, ensuring durability against abrasion, water, and fading. | Long-lasting printed products enhance customer satisfaction. |

| 2. Versatility Across Materials | Can print on textiles, plastics, wood, glass, and metals, allowing for customization. | Attracts diverse customer needs across industries. |

| 3. Efficiency through Gangheets | Maximizes material use by printing multiple designs on a single sheet. | Reduces waste and labor costs, allowing flexibility in production. |

| 4. Faster Turnaround Times | Shorter drying times lead to quicker production cycles. | Meeting tight deadlines enhances client satisfaction. |

| 5. Eco-Friendly Practices | Reduces VOC emissions compared to traditional inks, aligning with sustainability goals. | Attracts environmentally conscious consumers. |

Summary

UV DTF gangheet technology is a transformative approach that is reshaping the printing industry by delivering numerous advantages in quality, efficiency, and environmental sustainability. Businesses that adopt this innovative printing method enjoy high-quality outputs that are both durable and visually striking, thanks to the UV inks that cure quickly and adhere well to various surfaces. Additionally, the versatility of UV DTF printing allows for a wide range of materials to be used, catering to diverse customer needs and helping businesses stay relevant in a competitive market. Efficiency is further enhanced by the gangheet method, which optimizes material use and reduces waste, ultimately resulting in lower operational costs. With quicker turnaround times, businesses can fulfill orders promptly, meeting the demands of clients who require speed without compromising quality. Moreover, the eco-friendly characteristics of ultraviolet inks help reduce environmental harm, aligning businesses with the growing trend of sustainability. In summary, embracing UV DTF gangheet technology not only boosts operational performance, but also positions printing companies as leaders in an evolving landscape.