UV DTF Gang Sheets: The Future of Custom Apparel Printing

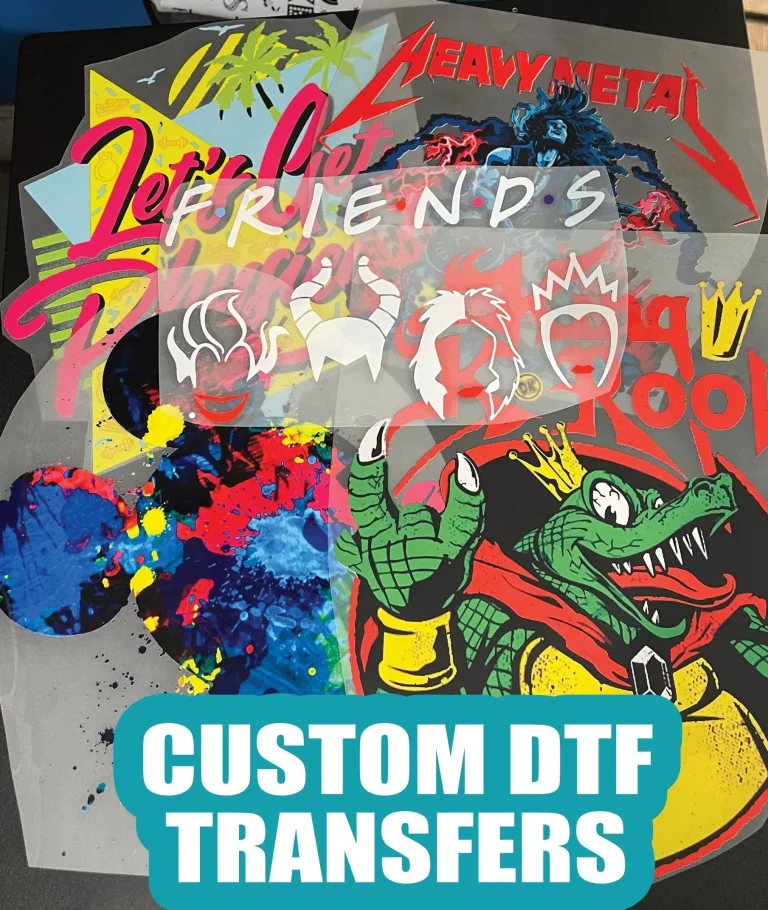

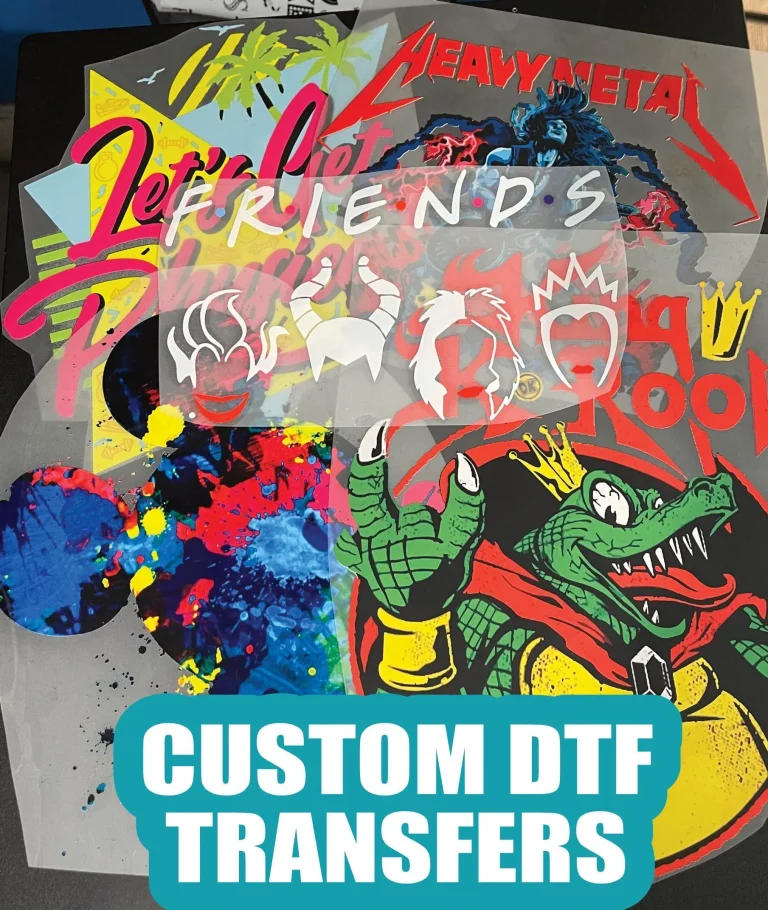

UV DTF gang sheets have emerged as a game-changer in the custom apparel printing landscape, incorporating cutting-edge UV printing technology with direct-to-film printing methods. This innovative approach not only enhances production efficiency but also elevates the quality of designs produced, making it an ideal choice for modern apparel businesses. By enabling multiple graphics to be printed simultaneously on a single sheet, UV DTF gang sheets help reduce material waste and costs, streamlining operations for printers. As the demand for unique and customizable apparel grows, these gang sheets exemplify the latest advancements in apparel printing innovations. Join us as we explore the transformative benefits and future prospects of UV DTF gang sheets in the custom apparel printing market.

In the realm of personalized clothing, the use of gang sheets in UV Direct-to-Film printing is revolutionizing how designs come to life. Known for their efficiency, these sheets allow for a wide range of designs to be printed at once, facilitating a more sustainable and cost-effective production process. With the rise of direct-to-film technology, businesses are now able to achieve vibrant prints that stand the test of time, catering to consumer preferences for high-quality, customized apparel. This blend of traditional and innovative techniques continues to shape the future of textile decoration, presenting exciting opportunities for both printers and their clientele. As we delve deeper into this topic, you’ll discover how UV DTF solutions are paving the way for new standards in the apparel printing industry.

Understanding the Mechanics of UV DTF Printing

UV Direct-to-Film printing (DTF) is an innovative printing technique that combines the best aspects of UV printing technology with the efficient process of DTF. This unique method allows for vibrant and durable prints that adhere exceptionally well to various material surfaces. By utilizing gang sheets, multiple designs can be printed on a single substrate, enhancing the overall efficiency of the printing process. This not only conserves material but also shortens production runs, making UV DTF printing an appealing choice for businesses aiming to streamline their operations.

The mechanics behind UV DTF printing involve transferring a specially formulated UV-sensitive ink onto a film, which is then cured instantly by UV light. This curing process ensures that the colors are vivid and resistant to fading over time. The result is a high-quality print that maintains its integrity, even after multiple washes. Understanding this technology is essential for businesses seeking to innovate within the custom apparel printing landscape, as it opens new avenues for creativity and efficiency.

The Advantages of Using Gang Sheets

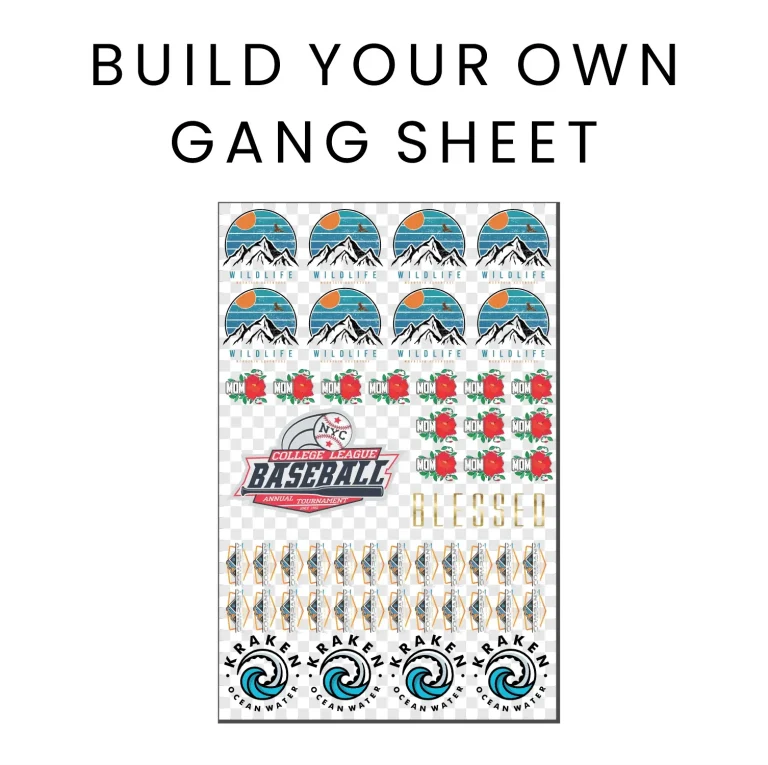

Gang sheets are pivotal in enhancing the efficiency of UV DTF printing. By allowing multiple designs to coexist on a single print sheet, printers can significantly reduce material waste and lower production costs. This means that businesses can produce a wider variety of designs without incurring additional expenses, enabling them to cater to customer preferences more effectively. Ultimately, the use of gang sheets leads to a more sustainable approach to custom apparel printing, aligning with modern consumer values.

Furthermore, the implementation of gang sheets contributes to a reduction in setup time for printing jobs. Since multiple designs are printed together, the time spent configuring the printer and preparing separate sheets is minimized. This streamlined process not only ensures quicker turnaround times but also heightens a business’s ability to respond to urgent customer demands, setting a new standard in the custom apparel printing market.

Quality Enhancement with UV DTF Technology

UV DTF printing technology is recognized for its superior print quality, a distinguishing factor when compared to traditional printing methods. The UV inks maintain vibrant colors and striking detail, allowing businesses to create intricate designs that stand out. After the print process, the UV curing solidifies the ink, rendering the finished product resistant to fading, peeling, and cracking, which are common issues associated with older printing techniques.

The durability of UV DTF prints addresses a fundamental need in the custom apparel sector: longevity. Customers demand products that not only look good when purchased but also retain their appeal over time. By providing high-quality and long-lasting prints through UV DTF technology, businesses can enhance customer satisfaction and build a loyal consumer base, leading to repeat orders and positive word-of-mouth referrals.

Cost Savings through Efficient Practices

The financial advantages of adopting UV DTF gang sheets are significant. By reducing material wastage through the gang print method, businesses can achieve remarkable savings that can be redirected toward other areas of growth, such as marketing or technological upgrades. This cost-effectiveness enables companies to maintain competitive pricing while still offering high-quality custom apparel.

Additionally, the speed of the UV DTF printing process means that businesses can take on more projects in a shorter timeframe. As operational efficiency increases, profit margins can expand without the need for increased labor or raw material costs. This dual benefit of reduced overhead and enhanced productivity creates a healthier bottom line, allowing businesses to thrive in a competitive market.

The Role of Sustainability in Modern Printing

Sustainability has become a vital focus within the custom apparel printing industry as consumers increasingly prioritize eco-friendly practices. The adoption of UV DTF printing combined with gang sheets supports this initiative by minimizing waste and optimizing resource use. Companies can effectively reduce their environmental impact while delivering high-quality products that meet market demands.

By emphasizing sustainable practices, businesses not only appeal to environmentally conscious consumers but also differentiate themselves from competitors who may not prioritize eco-friendly production methods. As sustainability becomes an integral part of brand identity, those utilizing UV DTF gang sheets position themselves as leaders in both innovation and environmental responsibility.

Emerging Trends Shaping Custom Apparel Printing

The custom apparel printing industry is witnessing an evolution influenced by the rise of personalization and customization. As UV DTF printing technology becomes more accessible, companies are increasingly investing in advanced printing solutions that allow them to offer unique designs tailored to individual customer preferences. This trend highlights the shift toward a demand-driven market where consumers crave products that express their personal styles.

Additionally, rapid technological advancements are facilitating quicker turnaround times. The efficiency of UV DTF processes means businesses can fulfill orders almost instantaneously—an essential capability in today’s fast-paced consumer environment. As the industry progresses, those that can adapt and implement these emerging trends will flourish, providing exceptional value in the custom apparel landscape.

Frequently Asked Questions

What are UV DTF gang sheets and how do they benefit custom apparel printing?

UV DTF gang sheets are large sheets used in UV Direct-to-Film printing to enable the simultaneous printing of multiple designs. This method increases efficiency by reducing setup time, minimizing material waste, and speeding up production. Businesses can enhance their profit margins while offering vibrant, high-quality prints that stand out.

How does UV DTF printing with gang sheets compare to traditional custom apparel printing methods?

UV DTF printing using gang sheets offers superior color vibrancy and durability compared to traditional screen printing. Unlike conventional methods, UV DTF can print on various materials, including textiles and hard surfaces, allowing for greater versatility in product offerings. This approach minimizes waste and improves turnaround times significantly.

What materials can UV DTF gang sheets print on?

UV DTF gang sheets can print on a wide range of materials including fabrics, leather, plastics, and even hard surfaces. This versatility makes UV DTF printing a valuable innovation for custom apparel printing, meeting diverse customer needs across different industries.

Are UV DTF gang sheets suitable for high-volume printing needs?

Yes, UV DTF gang sheets are ideal for high-volume printing because they allow for batch processing of multiple designs in one go. This leads to reduced production times and costs, making them an efficient choice for businesses looking to scale their custom apparel printing operations.

How do UV DTF gang sheets contribute to sustainability in the printing industry?

By minimizing wasted material and optimizing resource use, UV DTF gang sheets support sustainable practices in the printing industry. Their efficiency reduces the overall environmental impact of production, aligning with the growing consumer demand for eco-friendly options in custom apparel.

What emerging trends are associated with UV DTF gang sheets in custom apparel printing?

Emerging trends include increased investments in UV printing technologies, a shift towards customization and personalization of designs, rapid turnaround times for orders, and a heightened focus on print quality. Businesses using UV DTF gang sheets are well-positioned to capitalize on these trends and meet evolving consumer expectations.

| Key Points | Explanation |

|---|---|

| Definition of UV DTF Printing | A method combining UV printing technology with DTF process, allowing vibrant prints on various materials. |

| Increased Efficiency | Batch printing multiple designs on one sheet saves cost and time, leading to quicker turnaround. |

| Improved Quality | UV DTF prints offer superior vibrancy and durability with less fading or peeling, ensuring lasting quality. |

| Greater Versatility | This method can print on a range of materials, allowing businesses to diversify their product offerings. |

| Cost-Effectiveness | Reduced waste and improved efficiency lead to lower operational costs and competitive pricing. |

| Sustainability | Minimizing waste helps meet the industry’s push towards greener practices. |

| Emerging Trends | Investment in technologies, focus on customization, rapid fulfillment of orders, and emphasis on quality. |

Summary

UV DTF gang sheets represent a groundbreaking advancement in the custom apparel printing industry. Their ability to deliver high-quality designs, increase production efficiency, and enable sustainability makes them a compelling choice for businesses aiming to thrive in an increasingly competitive market. With growing consumer demand for customization and quick turnaround times, adopting UV DTF printing can help companies stay ahead of trends, ensuring they meet and exceed customer expectations. As this technology continues to evolve, it opens new avenues for creativity and innovation in apparel design, making UV DTF gang sheets a vital component of the future of custom printing.