UV DTF Gang Sheet: Revolutionizing Custom Apparel Printing

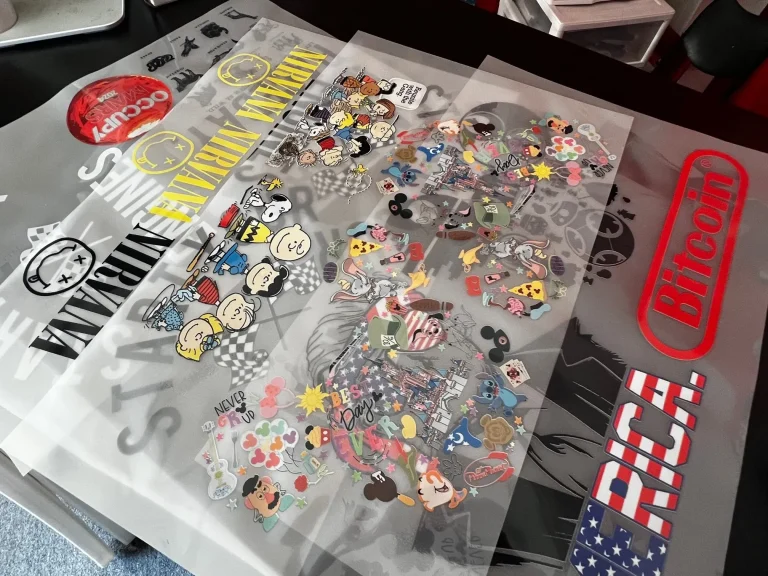

In the vibrant world of custom apparel printing, **UV DTF Gang Sheet** technology is leading the charge towards innovation and efficiency. This groundbreaking method integrates advanced UV printing technology with the popular DTF (Direct-to-Film) approach, allowing for multiple designs to be printed concurrently on a single sheet. As businesses strive to meet the growing demand for custom designs, the efficiency and versatility of gang sheet printing become indispensable. Moreover, the capabilities of UV DTF printing to deliver vivid colors and intricate details ensure that creations stand out, making it a game changer for artists and small enterprises alike. In this article, we’ll delve into the benefits of UV DTF Gang Sheet printing, recent advancements, and its profound influence on the custom apparel market.

Understanding the terms “direct-to-film printing” and “gang sheet printing” reveals the exciting developments in the realm of customized clothing and merchandise. Modern printing techniques, particularly UV printing technology, have revolutionized how designs are applied to fabrics, making the process faster and more cost-effective. The term “EazyDTF expansion” also captures the essence of this technological leap, emphasizing the importance of accessibility for businesses of all sizes. By maximizing resources and minimizing waste, these methods are reshaping the landscape of custom apparel, enabling creators to push boundaries in design and function. As we explore these terms, the synergy between innovation and creativity becomes apparent, heralding a new era in apparel customization.

The Evolution of Custom Apparel Printing Technologies

Custom apparel printing has seen an impressive evolution, moving from traditional screen printing methods to advanced digital techniques. The introduction of UV printing technology, in combination with direct-to-film (DTF) printing, marks a significant shift in how designs are applied to garments. This shift allows for a higher level of detail and vibrancy in prints, which is a game-changer for businesses wanting to create visually stunning custom apparel.

Moreover, these advancements have enabled slower flip markets to become faster and more efficient, empowering designers and printers with the tools needed for quick and high-quality production. As these technologies become more widely adopted, we can expect a continual enhancement of design capabilities and printing efficiency, solidifying the status of custom apparel as a vital market in fashion.

Understanding the Advantages of UV DTF Gang Sheet

The UV DTF Gang Sheet offers remarkable advantages for businesses looking to optimize their printing processes. By utilizing gang sheets, which allow multiple designs to be printed simultaneously, companies can drastically reduce material costs and waste. This efficiency is particularly beneficial for small businesses that may not have the capital to invest in large-scale production yet still want to deliver quality custom designs.

In addition to cost savings, UV DTF printing produces high-quality results that are resilient to wear and tear. The technology ensures that designs maintain their vibrancy over time, even after numerous washes. This level of durability not only satisfies customers but also enhances brand reputation. Overall, the advantages make UV DTF Gang Sheet printing an attractive option in the competitive landscape of custom apparel.

Furthermore, this printing method enhances creative possibilities. As it is compatible with various fabric types, designers can explore an array of materials and finishes, which gives them the freedom to implement unique design ideas. Such versatility fosters innovation, allowing brands to differentiate themselves in a crowded market.

Exploring EazyDTF’s Expansion in the Market

EazyDTF’s recent expansion into UV DTF printing highlights the burgeoning potential of this technology within the custom apparel industry. By investing in advanced large-format DTF printers, they are augmenting their production capabilities to meet the growing demands of their clientele. Their strategy also includes offering quick turnaround times with same-day shipping, a vital aspect for businesses operating in fast-paced environments.

This expansion not only emphasizes EazyDTF’s commitment to quality and efficiency but also sets a standard in the industry. As more players recognize the advantages of UV DTF printing, it is likely that competition will increase, leading to an overall improvement in product offerings. Such developments are a testament to how technological advancements can propel the entire market forward, giving every stakeholder an opportunity to thrive.

Technological Innovations in UV Printing

The realm of UV printing technology continues to evolve, bringing with it new innovations that enhance the capabilities of custom fabrication. Anker’s introduction of compact UV printers equipped to handle 3D texturing is one such development that adds a tactile dimension to printed designs. This technology allows for unique and intricate patterns that can enhance the perceived value of custom apparel.

The continuous innovation in UV printing not only expands creative horizons for designers but also equips businesses with tools to set themselves apart from competitors. By integrating these advanced techniques, they can respond to consumer demands for more differentiated and personalized products, thus addressing the growing trend of customization in fashion.

Accessibility for Independent Creators

The integration of UV DTF Gang Sheet printing technology has greatly improved accessibility for independent creators and small business owners. These technologies have removed previous barriers, allowing individuals to produce high-quality custom apparel without the need for substantial financial investments or extensive production facilities.

This democratization of custom printing means that aspiring designers can experiment with their ideas and cater to niche markets easily. As a result, the landscape of custom apparel is becoming more vibrant and diverse, offering consumers a broader range of choices and unique designs that resonate with personal style.

Future Trends in the Custom Apparel Market

The custom apparel industry is on the brink of a notable transformation, driven by technological innovations like UV DTF printing. As more manufacturers adopt these techniques, we will likely see a surge in competition, which will inherently push the standards for quality and efficiency higher. Businesses that embrace these advancements will not only gain a competitive edge but also contribute to an evolving marketplace that prioritizes creativity and personalized experiences.

Additionally, as sustainability becomes an increasingly important consideration in fashion, UV DTF printing’s efficiency can reduce waste significantly. This focus on sustainable practices combined with innovative technology can lead to the creation of ethically produced custom apparel, appealing to a growing consumer base that prioritizes environmental responsibility.

Frequently Asked Questions

What is a UV DTF Gang Sheet and how does it work in custom apparel printing?

A UV DTF Gang Sheet is a printing method that combines UV printing technology with direct-to-film (DTF) printing. This technique allows multiple custom designs to be printed simultaneously on a single film sheet, optimizing production efficiency and reducing costs. By utilizing gang sheets, businesses can save material costs while achieving vibrant colors and detailed prints on various fabrics.

What are the benefits of using UV DTF Gang Sheet printing for custom apparel?

The benefits of UV DTF Gang Sheet printing include cost efficiency, high quality, and versatility. This method allows businesses to print multiple designs in one batch, thus minimizing waste and production costs. Additionally, UV prints are durable and resistant to fading, making them ideal for apparel that requires longevity. The technique can also be used on diverse materials, expanding creative options for custom apparel.

How does the gang sheet concept enhance UV DTF printing efficiency?

The gang sheet concept enhances UV DTF printing efficiency by allowing multiple designs to be printed on a single sheet of film. This means businesses can produce various custom apparel items simultaneously, reducing setup times and material consumption. Consequently, this approach is particularly advantageous for small businesses or independent creators who need to manage costs while maintaining high-quality production.

What recent advancements in UV DTF Gang Sheet printing are impacting the custom apparel market?

Recent advancements include significant investments by companies like EazyDTF in large-format DTF printers, increasing production capacity and enabling same-day shipping. Additionally, innovations such as Anker’s compact UV printer, which supports 3D texturing, are enriching the custom printing landscape by offering unique features that enhance the visual and tactile quality of printed designs.

Can UV DTF Gang Sheets be used on different types of materials for custom apparel?

Yes, UV DTF Gang Sheets are highly versatile and can be used on a wide range of materials for custom apparel, including cotton, polyester, and blends, as well as hard surfaces. This flexibility allows businesses to explore unlimited design possibilities, making it an ideal choice for diverse custom apparel projects.

How is EazyDTF expanding its role in the UV DTF Gang Sheet printing sector?

EazyDTF is expanding its role in the UV DTF Gang Sheet printing sector by investing in new large-format DTF printers to boost their production capabilities. Their commitment to same-day shipping enhances their competitiveness in the market, allowing them to meet the fast turnaround times that consumers expect, thus solidifying their position in the custom apparel printing industry.

| Key Area | Details |

|---|---|

| What is UV DTF Gang Sheet Printing? | A combination of UV printing and direct-to-film printing that allows multiple designs to be printed on a single film sheet, enhancing efficiency and reducing costs. |

| Cost Efficiency | Reduces material waste and production costs, especially beneficial for small businesses producing small batches. |

| Quality and Durability | Produces high-quality, long-lasting prints that resist fading, cracking, and peeling after multiple washes. |

| Versatility | Can be applied to various materials, enhancing the possibilities for custom designs across different products. |

| Recent Industry Developments | Notable expansions and innovations from companies like EazyDTF and Anker that enhance production capacity and design quality. |

| Implications for Small Businesses | Enables greater access to quality printing for small businesses, fostering creativity and responsiveness to market trends. |

| Market Growth and Competition | Increased accessibility of UV DTF technology is likely to intensify competition, driving innovation and quality improvements in the market. |

Summary

UV DTF Gang Sheet is revolutionizing the custom apparel market by providing innovative solutions that cater to both small businesses and independent creators. This exciting technology combines advanced printing methods that enhance print quality while maximizing cost efficiency. With the ability to produce vibrant and durable designs that request minimal setups, businesses can keep pace with market trends and customer demands. The versatility of UV DTF printing also allows for a variety of applications, making it easier to create unique items that stand out. As industry leaders adopt this technology, the potential for growth and competition increases, setting the stage for a fully realized creative landscape in custom apparel design.