Texas DTF: Transforming Custom Apparel Across Texas

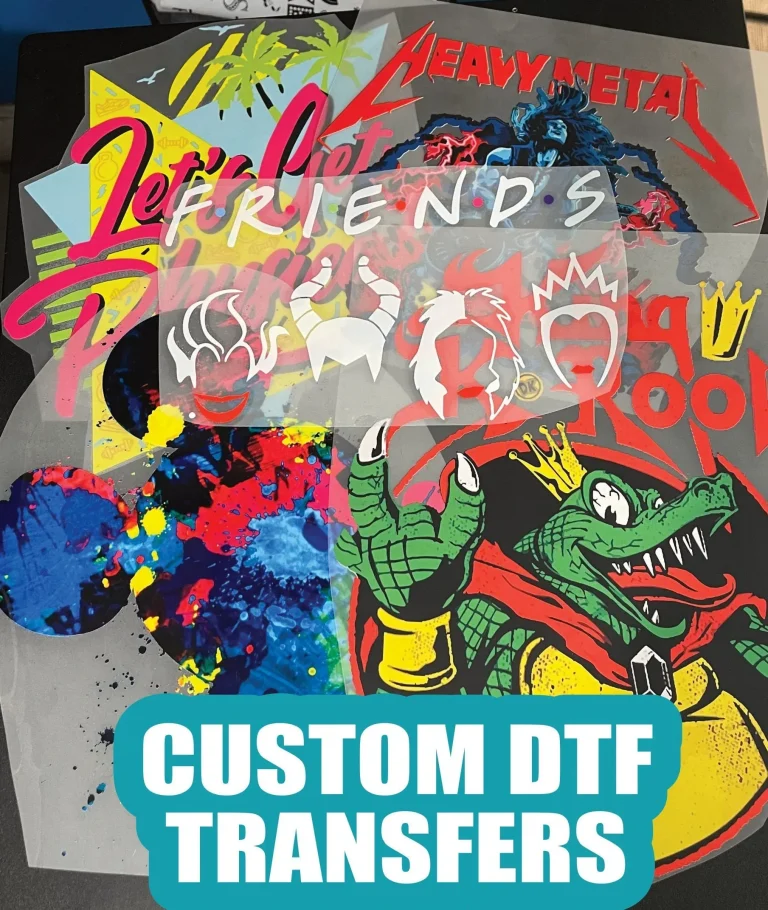

Texas DTF is reshaping the state’s apparel scene by blending bold design with cutting-edge print technology, empowering creators from boutique studios to major brands. This approach unlocks new opportunities for small studios and big brands alike to create vibrant, durable graphics on a wide range of fabrics, from soft cotton tees to performance blends used in outdoor events. DTF technology benefits are evident in faster turnarounds, more flexible order quantities, and excellent color reproduction that holds up under active Texas lifestyles, making it a practical choice for seasonal campaigns and on-demand drops. Direct-to-film printing handles white underlays on dark fabrics and scales from single-item runs to small batches with lower setup costs, while offering room for complex artwork, gradients, and bold color pops. As Texas shops compare methods, DTF remains a compelling option for creatives seeking high fidelity and practical production advantages, especially when agility, inventory control, and regional fashion trends matter.

In practice, the technology is often described as a film-to-fabric workflow, where a color-rich print is created on a transfer film and then heat-pressed onto diverse fabrics. Industry players may call it a modern digital transfer, a direct film transfer, or a rapid-prototyping method that supports on-demand customization for Texas brands. Viewed through an LSIs lens, this approach aligns with terms like digital garment decoration, heat-transfer film, and on-demand production while preserving the same benefits of fidelity, durability, and flexibility.

Texas DTF: Direct-to-Film Printing for Custom Apparel in Texas

Texas DTF printing has become a game-changer for boutique studios and large brands across the state. By embracing direct-to-film printing, Texas creators can produce vibrant, durable designs on a wide range of fabrics, enabling true custom apparel Texas with fast turnarounds and flexible order quantities. This approach aligns with the needs of Dallas, Houston, Austin, and San Antonio businesses seeking on-demand merchandise and bold graphics.

The DTF workflow—from digital design to film, powder application, and heat transfer—empowers brands to prototype quickly, test limited-edition runs, and scale up as demand grows. With strong color reproduction and reliable performance on dark fabrics thanks to the white underbase, Texas-based shops can push gradient effects and multicolor artwork that stand up to Texas temperatures and active lifestyles.

DTF Technology Benefits for Custom Apparel: Direct-to-Film Printing vs Screen Printing

DTF technology benefits include high color accuracy, a robust white underbase on dark fabrics, and the ability to print across a broad fabric range—from lightweight tees to dense hoodies. This versatility supports custom apparel Texas businesses that must serve diverse customer needs, from performance fabrics to cotton blends.

For brands evaluating DTF vs screen printing, the choice often comes down to order size and complexity of artwork. DTF excels with small runs, intricate multicolor designs, and quick proofs, offering faster lead times and reduced setup costs. Screen printing remains efficient for large-volume orders with simple color schemes, but DTF’s flexibility makes it a compelling option for Texas brands aiming to minimize inventory risk.

Frequently Asked Questions

What is Texas DTF printing and why is it a practical choice for custom apparel Texas brands?

Texas DTF printing uses the direct-to-film (DTF) process to transfer designs onto garments. The DTF technology benefits include high color accuracy and vibrancy, a white underbase on dark fabrics, broad fabric compatibility, and cost efficiency for small runs. This makes it a practical choice for custom apparel Texas brands that need fast turnarounds and durable results across cotton, blends, and performance fabrics.

DTF vs screen printing: which method works best for Texas-based shops producing custom apparel Texas?

DTF printing excels for small runs, complex multi-color artwork, and quick turnarounds, making it a strong choice for custom apparel Texas when orders are variable. It requires less setup than screen printing and handles a wider range of fabrics. Screen printing remains cost-effective for large-volume runs with simple color schemes but has longer setup times and color limitations. In short, choose DTF for on-demand, detailed designs and flexibility, and choose screen printing for big batches with straightforward artwork.

| Key Point | Details |

|---|---|

| Definition & Process | Texas DTF refers to the growing use of direct-to-film printing in Texas. The process prints designs onto a PET film, applies adhesive powder, and transfers the design to a garment with heat, delivering detailed, vibrant designs on a range of fabrics. |

| Benefits at a glance | High color accuracy and vibrancy; White underbase on dark fabrics; Versatility with fabrics; Cost efficiency for small runs; Strong durability after proper curing. |

| Fabric versatility | Works well on cotton, blends, polyester, and performance fabrics—well-suited for Texas’s outdoor, warm-climate wear. |

| White underbase capability | DTF can reproduce bright whites on dark fabrics, enabling faithful reproductions of complex artwork. |

| Color & detail | Broad color gamut with crisp images, suitable for multicolor designs and complex artwork. |

| Durability | When properly cured, DTF designs resist cracking and fading through many washes, important for active Texas lifestyles. |

| Cost efficiency | Reduces setup charges and downtime for small- to mid-sized runs compared with traditional screen printing. |

| Workflow in practice | Digital file preparation → print on PET film with white and color inks → apply adhesive powder → cure → transfer with heat and pressure; enables rapid prototyping and small-batch production. |

| DTF vs screen printing | DTF shines for smaller runs, intricate artwork, and quick turnarounds; screen printing remains cost-effective for large runs with simple color schemes but involves longer setup. |

| Best use cases in Texas | Ideal for indie brands, on-demand orders, sports teams, schools, event merch, boutiques—especially where quick turns and customization are valued. |

| Texas market context | Dallas, Houston, Austin, and San Antonio shops leverage DTF to deliver fan merch, corporate gifts, and spirit wear, aligning with Texas climates and outdoor activities. |

| Provider considerations | Focus on quality, color accuracy, white underbase performance, material compatibility, reliable turnaround times, sustainability, and strong customer support. |

| Future outlook | Advances in inks, printers, and films will improve color fidelity, wash durability, and fabric compatibility, enabling more personalized, fast-to-market offerings for Texas brands. |

Summary

Conclusion: Texas DTF is transforming the Texas apparel landscape by delivering vibrant, durable designs with flexible production and faster time-to-market. This technology empowers Dallas, Houston, Austin, and San Antonio brands to offer on-demand, customized merch that meets the needs of Texas consumers while reducing inventory risk. As ink formulations, film materials, and printers continue to evolve, Texas DTF will further enhance color accuracy, white underbase performance on dark fabrics, and overall production agility, helping Texas-based artists, boutiques, and print shops scale creative offerings and grow in a dynamic market.