Texas DTF Prints: How to Achieve High-Quality Every Time

Texas DTF prints are redefining how apparel decorators in the Lone Star State deliver vibrant, durable designs across fabrics, including jerseys, fleece, and moisture-wicking blends. The core idea is simple: build a repeatable workflow that balances meticulous prepress, precise transfer, and dependable curing so every batch meets or exceeds expectations while keeping production scalable. Investing in the right equipment—robust printers, high-quality film, and consistent adhesive powders—pays off in color accuracy, edge sharpness, and predictable results that scale with demand. DTF ink longevity is achieved by careful matching of ink chemistry to the substrate and by following proven curing parameters that minimize fading or cracking over time. If you commit to disciplined workflows, your output remains consistent across shifts, suppliers, and seasons, strengthening customer trust and your business’s reputation for reliability in a competitive market, while a mindset of ongoing learning and supplier collaboration helps you keep pace with evolving fabric blends.

In broader terms, this approach is described in the market using terms like DTF technology for apparel decoration, heat-transfer film methods, and substrates-ready inks that bond securely to cotton, poly blends, and athletic fabrics. These alternatives emphasize durability, soft hand feel, and wash-fast color, which aligns with the expectations brands have when choosing transfer-based solutions. Focusing on equipment quality, color management, and efficient curing yields a scalable workflow that remains consistent across varied garment mixes. The underlying principles—careful prepress, accurate temperature and pressure settings, and proper drying times—translate across different substrates, ink systems, and film types, making the technique adaptable to multiple market niches. As you evaluate suppliers and material bundles, prioritize options that highlight ink longevity, film consistency, and end-to-end process support to cement repeatable, high-quality transfers.

Texas DTF prints: Achieving Consistent Color, Durability, and Ink Longevity

In Texas, achieving repeatable Texas DTF prints starts with selecting dependable hardware and consumables. The foundation is the printer, DTF film, adhesive powder, and the ink system. When you invest in the best DTF printers Texas has to offer, you gain color accuracy, print sharpness, and ink longevity that influence how vibrant and durable every batch appears. Look for printers designed for DTF transfer rather than pure DTG, with stable heads, robust firmware, and RIP software that lets you precisely control color profiles for consistent results.

Color management and prepress are critical before you press print. Calibrate monitors for accurate skin tones and bold colors, export designs in a RIP-friendly color space, and maintain clean vector outlines with high-resolution bitmaps to avoid edge softness. This preflight discipline helps ensure that what you see during DTF printing Texas translates into reliable on-fabric results, reducing waste and reprints while boosting the overall DTF prints quality through disciplined transfer tips and careful curing.

Choosing Equipment and Materials: Best DTF Printers Texas, Substrates, and DTF Transfer Tips

Selecting the right equipment and materials sets the stage for scalable, high-quality Texas DTF prints. Prioritize a printer optimized for DTF transfer, high-quality DTF film with uniform thickness, evenly flowing adhesive powder, and inks compatible with your substrate. When you align these components—the printer, film, adhesive, and ink—you create a system that drives predictable output and stronger DTF ink longevity. If you’re researching “DTF printing Texas” options, a balanced setup will help you deliver consistently vibrant DTF prints quality across jobs.

Substrate choice and post-processing are just as important as the printer itself. Consider fiber content, weave, care instructions, and how the coating or pre-treatments interact with the adhesive film. Build a short test matrix to identify the best combinations for cotton, polyester, blends, and stretch fabrics, and document your curing, washing, and finishing steps. With clear standard operating procedures and a formal testing phase for new materials, your Texas DTF prints remain durable and visually consistent, reinforcing customer trust and protecting your brand’s quality reputation.

Frequently Asked Questions

What factors influence DTF prints quality in Texas DTF printing, and how can I optimize for consistency across batches?

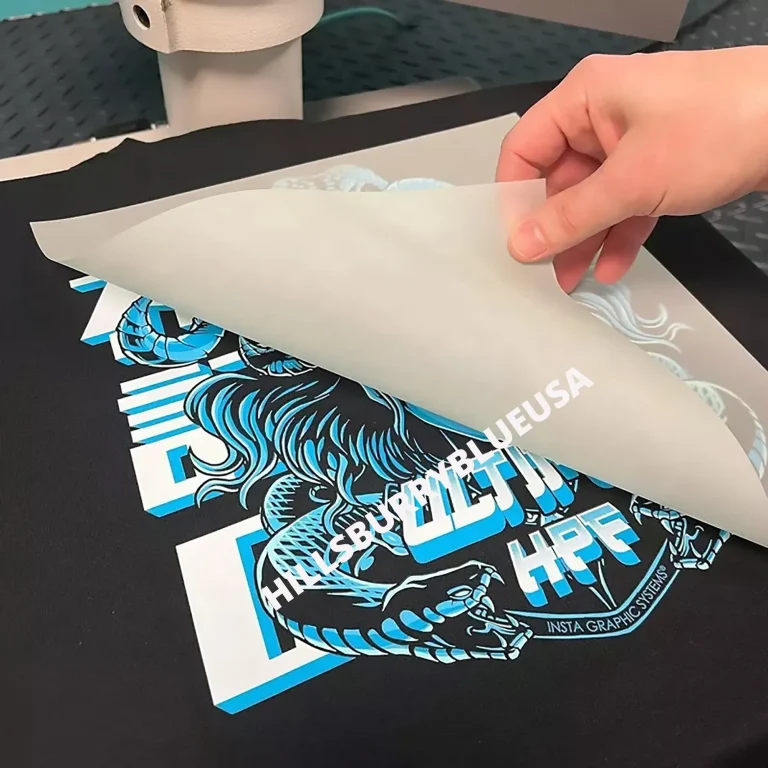

Key factors shaping DTF prints quality in Texas include equipment and materials, color management, transfer parameters, substrate selection, and curing/post-processing. Use reliable DTF printers Texas with compatible, high-quality film, adhesive powder, and inks to improve color accuracy and ink longevity. Implement solid color management (calibrate displays, use ICC profiles, and trusted RIP settings) to ensure designs translate predictably to fabric. Optimize the transfer: preheat, correct time and pressure for each fabric, and choose the appropriate peel method to avoid ghosting. Choose substrates with suitable fiber content and care instructions, and cure properly to fix inks and adhesive. Finally, document standard operating procedures and run test swatches whenever you change materials to maintain consistent Texas DTF prints across batches.

What are the best DTF printers Texas options and practical DTF transfer tips to maximize ink longevity and ensure durable Texas DTF prints?

Best DTF printers Texas options should be printers designed for DTF transfer with stable print heads, robust firmware, and RIP software that provides precise color control. Ensure compatibility with your chosen DTF film and inks, and consider overall cost and ink longevity when evaluating options. Practical DTF transfer tips include preheating and testing on a sample, dialing in the right pressure and time for each fabric, and choosing the correct peel method (cold or warm) for the substrate. Decide on matte vs gloss finishes based on garment color and fiber content, and test across substrates (cotton, polyester, blends, etc.). For longevity, use inks matched to the substrate and ensure proper curing, then provide customers with simple care instructions to preserve color. Finally, standardize your workflow with documented procedures and regular QA checks to keep Texas DTF prints consistent and durable.

| Topic | Key Points | Relevance to Texas DTF prints | Practical Tips |

|---|---|---|---|

| Introduction | DTF tech enables rich color, soft hand feel, and durability; emphasizes consistency across batches and a Texas-focused workflow. | Texas market requires reliable, repeatable DTF workflows due to climate, supplier options, and diverse customer demands. | Define quality benchmarks for color, wash-fastness, and batch-to-batch consistency. |

| Right equipment & materials for DTF printing | Reliable hardware and consumables: printer, DTF film, adhesive powder, ink system; RIP software improves color control. | Equipment foundation influences color accuracy and longevity in Texas markets. | Choose printers designed for DTG-like workflows optimized for DTF; test substrate compatibility and maintain consistent material quality. |

| Color management & design preparation | Calibrate monitor, export designs in a RIP-friendly color space, maintain clean vector outlines and high-res bitmap artwork; implement ICC profiles. | Predictable color across Texas fabrics and batches; reduces waste and reprints. | Create and apply ICC profiles; ensure RIP supports the color workflow and export in the correct space. |

| Optimizing transfer process | Preheat platen, optimize pressure/time for fabric type; peel method choices; decide matte vs gloss; test across substrates. | Crucial for consistency across diverse Texas textiles. | Develop a short test matrix; document ideal settings per substrate; follow film manufacturer guidance. |

| Substrates, ink longevity, and durability | Fabric variety affects color brightness, edge sharpness, and dye-fastness; care about fiber content, weave, and coatings; curing impacts longevity. | Durability requirements due to frequent washing and wear in Texas markets. | Test wash durability; select compatible substrates; use coatings or pre-treatments when appropriate; ensure proper curing. |

| Curing, washing, and finishing | Curing locks transfer into fabric; manage temperature, time, and pressure; post-curing care and customer washing instructions. | Improved color density, hand feel, and long-term adhesion; reduces post-process issues. | Follow manufacturer guidelines; allow cooling; provide care instructions to customers to preserve results. |

| Troubleshooting common issues | Color shifts, edge blurring, white ink gaps, and adhesion failures; use a methodical approach to diagnose. | Maintains quality across fabric variations and Texas conditions. | Document symptoms, verify ICC/RIP settings, adjust curing, and retest with controlled samples. |

| Building a scalable, repeatable Texas DTF prints workflow | SOPs, checklists, and formal testing for new materials; documented steps improve predictability and throughput. | Supports business growth in Texas by delivering consistent output. | Document steps, enforce QA checks, and iterate with new materials; implement regular process reviews. |

Summary

Texas DTF prints are the result of a clear, end-to-end system that combines the right equipment, color management, transfer technique, substrate selection, and proper post-processing to deliver repeatable, durable results. In Texas shops, climate and supplier variability make a documented workflow essential to maintain color fidelity, wash-fastness, and consistent hand feel across batches. By following the steps outlined—equipment choices, color-managed design, optimized transfer, substrate compatibility, curing, and customer care—you can achieve industry-grade Texas DTF prints that meet customer expectations. A strong emphasis on SOPs, testing, and ongoing optimization helps protect your brand and keeps customers returning.