Quality DTF Supplies: A Pro Guide to Superior Results

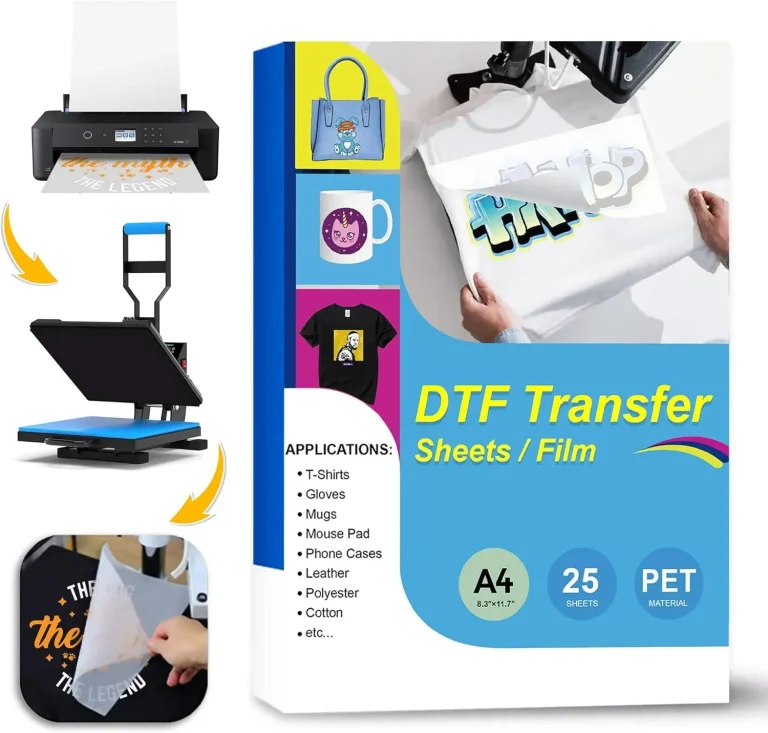

quality DTF supplies are the foundation of reliable, repeatable results in direct-to-film printing, influencing color accuracy, adhesion, and long-term durability. From DTF transfer film and the powders to inks and transfer paper, every component must work in harmony to minimize waste and misregistration. Choosing quality materials isn’t about the cheapest option, but about understanding how films, inks, and powders interact under heat and pressure on your typical substrates. In practice, evaluate each category—DTF transfer film, powders, inks, and paper—against consistent performance benchmarks such as cohesion, wash fastness, and color stability. A disciplined selection process that prioritizes compatibility will keep production moving smoothly, reduce reprints, and yield predictable outcomes.

To frame the topic through an LSI lens, think in terms of print media quality, coating consistency, and system compatibility rather than a single consumable. Materials such as media films, pigment inks, and bonding powders form a cohesive ecosystem that shapes color fidelity, edge sharpness, and wash durability. Substrates—cottons, polyester blends, and synthetics—respond differently, so selecting reliable transfer films and compatible papers with predictable heat response is essential. Beyond the consumables, aligning printer profiles, curing schedules, and finishing steps completes the quality loop and supports scalable production.

Quality DTF supplies for reliable color, adhesion, and wash durability

In the world of DTF printing, the outcome hinges on using quality DTF supplies that work in harmony across every step of the process. From the DTF transfer film to the inks, powders, and DTF transfer paper, each component affects color accuracy, adhesive performance, and wash durability. A pro approach means evaluating how these materials interact within your typical workflow and substrates, rather than choosing the cheapest option. When you prioritize quality DTF supplies, you set a foundation for repeatable results, reduced reprints, and smoother production runs.

A practical evaluation begins with the core categories: DTF transfer film, DTF ink quality, and DTF transfer paper. By examining coating uniformity, thickness stability, and curl resistance of the film, you improve edge crispness and color transfer. Assess ink quality for color gamut, lightfastness, and curing compatibility with your coating system, while selecting transfer papers with high whiteness and predictable heat response. Together, these elements shape color fidelity, adhesion strength, and overall finish, underscoring why quality DTF supplies matter for professional shops.

Mastering the DTF printing workflow: film, ink, paper, and printer compatibility

Achieving consistent results starts with ensuring the various DTF supplies you choose are compatible and calibrated to your printer and RIP workflow. DTF transfer film properties—thickness, gloss, and surface stability—must align with your ink system and powder formulation to prevent issues like ghosting or adhesion inconsistency. Paying attention to DTF printer compatibility, including firmware and profile support, helps minimize downtime and ensures repeatable color management across runs.

A systematic approach to testing and supplier evaluation reinforces reliability. Request test kits that cover the full mix of DTF supplies, run standard motifs on your common fabrics, and compare results for color accuracy, edge clarity, and wash durability. Document findings and use them to select a balanced combination of DTF transfer film, DTF ink quality, and DTF transfer paper that complements your printer, substrates, and finishing process—optimizing the entire workflow from print to post-processing.

Frequently Asked Questions

What should I look for when evaluating quality DTF supplies to ensure reliable color and adhesion, with emphasis on DTF transfer film and DTF ink quality?

Key indicators of quality DTF supplies include: DTF transfer film with uniform coating, stable thickness, minimal curl, and reliable adhesion with your powder; and DTF ink quality that offers strong color gamut, good lightfastness, consistent dry times, and compatibility with your printer and coating system. Pairing these with high-quality DTF transfer paper and compatible powders helps minimize ghosting and wash issues. To verify, request a test kit or samples, print on your typical fabrics, and assess color accuracy, edge sharpness, adhesion after washes, and ease of powder removal. Also check storage stability, odor, batch traceability, and supplier support. A balanced combination reduces reprints and downtime.

Why is printer compatibility important when selecting quality DTF supplies, and how can I verify it for a smooth workflow?

Printer compatibility matters because even excellent DTF transfer film, inks, and papers may underperform if they don’t match your printer model, RIP software, and heat-press workflow. Confirm that the ink set is compatible with your printer and that profiles, curing times, and temperatures align with the media you chose. Ensure the DTF transfer film and DTF transfer paper have documented compatibility with your printer, and that the accompanying powders work with your substrate. Ask suppliers for compatibility data, firmware notes, and sample packs, then run a small test kit across your usual fabrics to evaluate color accuracy, adhesion, and wash durability. Consider total cost of ownership and supplier support when choosing a brand.

| Topic | Key Points |

|---|---|

| Introduction |

|

| Why quality matters |

|

| Core categories to evaluate |

|

| Supplier evaluation |

|

| Testing workflow |

|

| Storage, handling, and care |

|

| Common pitfalls and red flags |

|

| Buying checklist for the pro shop |

|

Summary

The table above summarizes the key points about choosing and using quality DTF supplies to achieve consistent, professional results across various substrates.