Perfect Color DTF Transfers: Tips and Tricks for Success

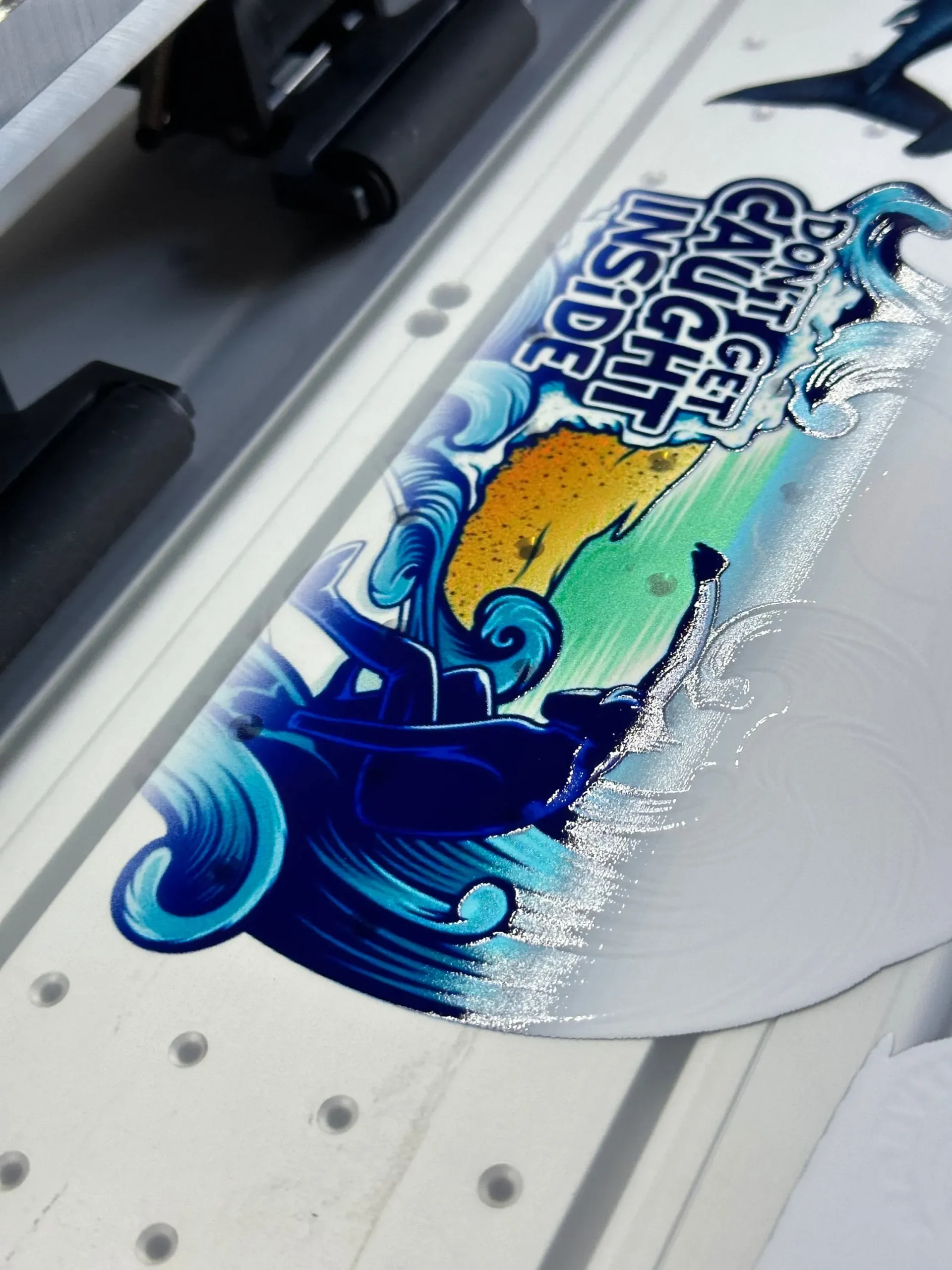

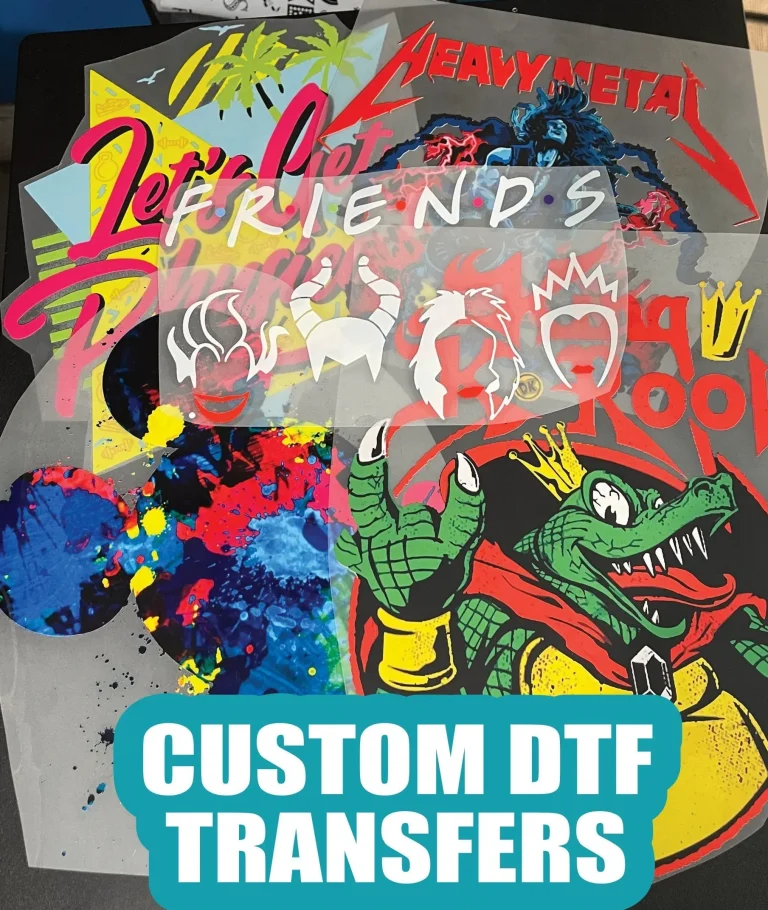

Perfect Color DTF Transfers are transforming the textile printing landscape, offering unparalleled vibrancy and precision to customize fabrics. This innovative process not only ensures excellent color accuracy but also expands your creative possibilities, whether you’re a professional printer or a crafting enthusiast. To achieve the finest results, understanding essential DTF printing tips is crucial, such as selecting high-quality materials and utilizing effective DTF printing techniques. In this article, we’ll delve into strategies tailored for perfect color DTF transfers, including the significance of the right transfer paper for DTF applications. Prepare to elevate your designs with expert insights to achieve stunning, high-quality DTF transfers that last.

The world of Direct to Film (DTF) transfers has opened exciting avenues for vibrant fabric printing, appealing to both commercial businesses and DIY aficionados. The art of DTF printing encompasses a variety of techniques designed to maximize color fidelity and enhance transfer quality. Many practitioners are now exploring methods that not only focus on print settings but also on the choice of transfer materials and processes that ensure enduring performance. Whether you’re familiarizing yourself with adhesive powders or seeking to optimize printer calibrations, mastering these aspects is key to successful color representation. This exploration will guide you through the intricacies of producing exceptional transfer designs that captivate and last.

The Importance of High-Quality DTF Transfers

In the world of DTF printing, the significance of using high-quality materials cannot be overstated. High-quality DTF transfers ensure not only vibrant colors but also a durable finish that withstands the rigors of washing and wearing. When you select premium PET films and top-tier adhesive powders, you’re investing in the longevity of your printed designs. This means less time spent on reprints and repairs, allowing you to focus more on creativity rather than correcting mistakes.

Moreover, using high-quality DTF inks is crucial for color accuracy and fidelity. Low-quality inks can result in muted colors that do not reflect your original design intent. By choosing reputable brands, you enhance the vibrancy and richness of your transfers, ensuring they pop on any fabric. Thus, continual investment in high-quality materials is pivotal for any DTF printing project.

Mastering DTF Printing Techniques for Vibrant Colors

When it comes to DTF printing, mastering specific techniques can significantly elevate the vibrancy of your colors. Techniques such as color mixing allow for endless creative possibilities. By blending multiple colors, you can achieve unique shades that not only enhance your designs but also convey a sense of authenticity and individuality. This artistic approach not only distinguishes your work but also captivates your audience by showcasing your creative ingenuity.

In addition to color mixing, incorporating layering effects can transform a simple design into a stunning visual masterpiece. Layering allows for depth and dimension, making your DTF transfers more dynamic. Each layer can be treated individually, providing opportunities for experimenting with different textures and hues. By harnessing these techniques, you can ensure that each transfer captures attention and resonates strongly with your audience.

Printer Calibration for Perfect DTF Transfers

Ensuring perfect color in DTF transfers begins with meticulous printer calibration. If your printer’s ink density settings are improperly calibrated, the vibrancy of your colors could be compromised. For instance, using higher ink densities on dark fabrics facilitates more vivid color transfers; conversely, lighter fabrics may require a gentler touch. Understanding your fabric’s needs is key to achieving the best print quality.

Moreover, it’s essential to configure your printing software to the specific profiles needed for DTF. This step guarantees that what you see on your screen directly translates to your printed product. A seamless match between visual representation and the final transfer is crucial for maintaining color accuracy and quality, ensuring that your designs turn out exactly as you envisioned.

Selecting the Right Transfer Paper for DTF

Choosing the right transfer paper is a pivotal step in achieving impeccable results with DTF printing. Not all transfer papers are suited for this technique; thus, it’s imperative to opt for papers specifically designed for DTF applications. The right transfer paper facilitates better adhesive bonding and color transfer, ultimately enhancing the overall vibrancy of your designs.

To determine which papers suit your needs best, it’s wise to conduct tests with various types of DTF papers. Evaluate how each type reacts with your designs, focusing on aspects such as color brightness and durability after multiple washes. This practical approach ensures you make informed decisions that will culminate in outstanding high-quality DTF transfers that reflect your artistic vision.

Color Accuracy in DTF Printing: Tips and Tricks

Achieving impeccable color accuracy in DTF transfers is essential for ensuring that your designs appeal to the market. Start by maintaining a consistent color workflow from your design software to the printer settings. Utilize color calibration tools to establish a reliable baseline for all your projects, enabling you to replicate success with every print.

Moreover, consider the impact of lighting conditions while designing and printing. Natural light can significantly affect how colors are perceived; therefore, keeping your workspace well-lit allows for better color judgment. Taking these proactive steps enhances the overall color fidelity of your DTF prints, leading to visually stunning outcomes that align with your initial design intentions.

Creative Applications of DTF Transfers

The versatility of DTF transfers opens the door to innovative creative applications. From custom apparel to personalized gifts, the possibilities are endless. Embedding unique designs that resonate with individual styles allows for the creation of exclusive items that stand out in a crowded market, appealing to a wide array of customers looking for personalization.

Additionally, DTF transfers can be utilized in various contexts—such as promotional materials, event merchandise, or even home décor items. By experimenting with different substrates, artists can push the envelope of creativity, resulting in vibrant pieces that not only showcase their artistic prowess but also meet the demands of a diverse audience.

Frequently Asked Questions

What are the best practices for achieving perfect color accuracy in DTF transfers?

To achieve perfect color accuracy in DTF transfers, ensure you use high-quality DTF inks and PET films, calibrate your printer settings correctly, and select appropriate transfer paper for DTF printing. Experimenting with different color mixing techniques can also enhance the vibrancy of your designs.

How does printer calibration affect the quality of high-quality DTF transfers?

Printer calibration is crucial for high-quality DTF transfers as it ensures the ink density and color profiles match the desired output. Proper adjustments to ink density and ensuring your software supports DTF color profiles are essential for achieving stunning and accurate color results.

Which transfer paper is best for DTF printing?

For DTF printing, specialized DTF papers are highly recommended as they are designed to deliver optimal results. Make sure to test different types of transfer paper for DTF to see which provides the best color vibrancy and washing durability for your specific fabric.

What are some tips to improve the vibrancy of colors in DTF transfers?

To improve color vibrancy in DTF transfers, use high-quality DTF inks, ensure your printer is well-calibrated, and select the right transfer paper. Additionally, utilizing layering techniques and experimenting with color mixing can also help create more vivid designs.

What is the impact of using low-quality materials on DTF printing results?

Using low-quality materials in DTF printing can lead to dull colors, poor adhesion, and overall unsatisfactory transfer results. High-quality PET films, inks, and adhesives are essential for vibrant, long-lasting DTF transfers that maintain color integrity after washing.

Are there specific DTF printing techniques to enhance design creativity?

Yes, specific DTF printing techniques such as color mixing and layering designs can significantly enhance creativity in your projects. Experiment with blending colors to create unique shades and layer different designs to add depth, ensuring your prints stand out and capture attention.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers offer vibrant color and intricate designs on various fabrics. |

| High-Quality Materials | Invest in PET films, high-quality adhesive powders, and durable DTF inks to enhance color vibrancy and longevity. |

| Printer Calibration and Settings | Adjust ink density, set up software for DTF color profiles, and fine-tune heat press settings for optimal results. |

| Transfer Paper Selection | Use specialized DTF transfer papers for best outcomes; conduct tests on different papers to find the most effective. |

| Creative Techniques | Experiment with color mixing and layering effects for unique and rich designs. |

| Actionable Tips | Maintain a clean workspace, test various substrates, and perform regular maintenance for consistent output. |

Summary

Perfect Color DTF Transfers can transform your fabric designs with their rich vibrancy and intricate details. Achieving the ideal color in DTF printing involves understanding key factors such as high-quality materials, precise printer settings, and creative techniques. Investing in top-notch PET films and inks is crucial for vibrant transfers, while proper calibration ensures accurate color reproduction. Experimenting with different transfer papers and techniques can elevate your designs, guaranteeing a standout finish. With practice and attention to detail, creating stunning transfers that withstand the test of time is well within reach.