Optimize UV DTF Printing: Maximize Your Profits Today!

To truly thrive in today’s competitive market, print shop owners must learn how to optimize UV DTF printing effectively. This innovative direct-to-film method utilizes ultraviolet light to create vibrant and durable prints on a variety of materials, making it a compelling choice for modern printing needs. By understanding the nuances of UV DTF printing, you can streamline your operations and significantly boost your profit margins. It’s not just about keeping pace but also about standing out by maximizing profits in printing through smart optimization strategies. As we delve into the various facets of print shop optimization, you’ll discover how to elevate your business and meet the growing demands of your customers.

When exploring the realm of contemporary printing, it’s essential to grasp key methodologies like direct-to-film technology, often referred to as DTF printing. This advanced process not only enhances print quality but also broadens the creative possibilities for applying designs on diverse surfaces. Using an ultraviolet curing system, print shop owners can achieve remarkable color vibrancy while minimizing production time. Understanding the intricacies of this printing technique opens doors for maximizing profits in printing and optimizing your print shop’s overall performance. As we explore various optimization tactics, you’ll learn how to harness the full potential of this innovative printing solution.

Understanding the Benefits of UV DTF Printing

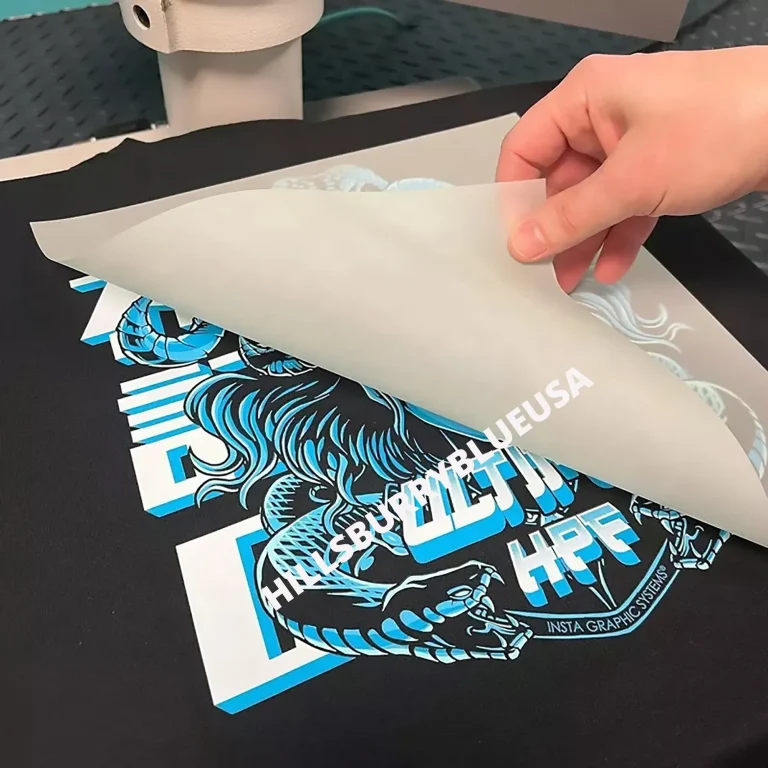

UV DTF printing, or Direct to Film printing, offers a multitude of advantages that can greatly impact a print shop’s profitability. This innovative technique utilizes ultraviolet light to cure inks, resulting in vibrant colors and durable prints on a variety of substrates including textiles, wood, and metals. This versatility not only attracts a broader customer base but also allows for customization in product offerings, ensuring that businesses can cater to niche markets and individual client needs.

Moreover, the efficiency of UV DTF printing can significantly reduce waste and production times. Unlike traditional methods that may require longer curing times and layered applications, UV DTF printing dries instantly under UV light. This rapid processing enhances workflow speeds, enabling print shops to complete more jobs in a shorter timeframe, thereby maximizing profitability across various jobs while maintaining high-quality standards.

With the rising demand for personalized and high-quality printing, understanding UV DTF printing becomes imperative for print shop owners. By leveraging the strengths of this technology, businesses can focus on quality output and operational excellence, which are crucial for standing out in a competitive marketplace.

Regular Maintenance for Optimal UV DTF Performance

To ensure that you are getting the most out of your UV DTF printing setup, regular maintenance is crucial. This includes not only routine cleaning of printer heads and ensuring that ink flows appropriately, but also calibrating the equipment for optimal performance. Failure to maintain the equipment can lead to costly errors, such as misprints and equipment breakdowns, which can impair productivity and, ultimately, profitability.

Scheduled maintenance goes beyond cleaning; it is about ensuring all components of the printing system are in top shape. For instance, regularly checking the ink viscosity and ensuring it meets manufacturer specifications can lead to better print quality and fewer print failures. By establishing a comprehensive maintenance schedule, print shop owners can prevent unexpected downtimes, allowing for steady workflow and production consistency.

Invest in Quality Materials for Better Output

The foundation of superior prints lies in the quality of the materials used in the UV DTF printing process. High-quality films and inks not only enhance the vibrancy and longevity of prints but also minimize the need for reprints. In a landscape where customer satisfaction directly correlates with repeat business, investing in trusted brands can differentiate your offerings from competitors who may skimp on the essential materials.

Moreover, the compatibility of materials with the UV printing process is an often-overlooked aspect that can drastically impact the final product’s quality. Properly researched and selected materials ensure that prints adhere well and pass the durability tests over time. By prioritizing high-quality materials, print shops can maintain a reputation for excellence, boost customer retention, and substantiate higher pricing due to the superior quality of finished products.

Calibrating Equipment for Consistent Quality

Proper calibration of printing equipment is instrumental in achieving consistent and high-quality results in UV DTF printing. This involves adjusting settings such as resolution, color balance, and print speed based on the substrate being used and the specific project requirements. An improperly calibrated printer can lead to various issues including color mismatches and print distortion, resulting in waste and impacting overall profitability.

Investing time in calibrating your printers should be a routine part of your production process. Regularly testing prints and adjusting settings as necessary will help achieve color accuracy and detail, which are particularly important in custom printing jobs. As print shops enhance the consistency and quality of their products, they can efficiently attract more customers and secure a solid market presence.

Analyzing Cost-Effectiveness for Profit Maximization

Regularly analyzing the cost-effectiveness of your UV DTF jobs is crucial to maximizing profits. Understanding each component involved in the production process—from ink and film costs to labor and overhead—is essential for effective pricing strategies. By keeping meticulous records of expenses associated with each job, print shops can identify areas of unnecessary spending and optimize resource allocation.

Once you have a clear picture of costs, you can adjust pricing structures to remain competitive while ensuring margins are sustainable. Consider implementing tiered pricing based on the complexity and size of orders, which can help in attracting a wider clientele while catering to different budget needs. This practice not only maximizes profitability but also strengthens customer relationships by offering tailored solutions.

Effective Marketing Strategies to Enhance Visibility

In the digital age, having effective marketing strategies is vital for attracting customers to your UV DTF print shop. Utilizing social media platforms such as Instagram and Facebook can help showcase your high-quality prints and demonstrate their unique properties. Engaging with followers by sharing customer testimonials and project highlights can establish credibility and build a reputable presence in the community.

Exploring online marketplaces can also significantly broaden your reach. Listing your UV DTF products on platforms like Etsy or Amazon allows you to tap into a vast audience searching for customized printing services. Highlighting the unique aspects of your offerings—not just in quality but also in customer service and speed—can help convert casual browsers into loyal customers.

Frequently Asked Questions

How can I optimize UV DTF printing in my print shop?

To optimize UV DTF printing, focus on regular printer maintenance, invest in high-quality films and inks, and calibrate your equipment properly. These steps ensure better print quality, reduce operational downtime, and lead to higher customer satisfaction.

What are the benefits of understanding UV DTF printing for my business?

Understanding UV DTF printing allows you to leverage its advantages, such as vibrant colors and durability, which can attract more customers. By optimizing UV DTF printing processes, you can maximize profits and enhance your print shop’s reputation.

What materials should I use for maximizing profits in UV DTF printing?

For maximizing profits in UV DTF printing, invest in high-quality films and UV inks compatible with your printing equipment. Quality materials not only improve print clarity and longevity but also minimize the need for reprints, contributing to overall cost savings.

How does print shop optimization impact UV DTF printing efficiency?

Print shop optimization involves streamlining workflows, reducing waste, and implementing automation where possible. This increases production speed and lowers operational costs, thereby enhancing the efficiency of UV DTF printing and improving profit margins.

What marketing strategies are effective for promoting UV DTF printing services?

Effective marketing strategies for promoting UV DTF printing services include leveraging social media platforms to showcase your work, using customer testimonials, and exploring online marketplaces. Highlighting customization options can also attract a broader audience.

How can data analytics improve my UV DTF printing operations?

Data analytics can provide insights into sales trends and customer preferences, allowing you to make informed decisions about production and pricing. By optimizing UV DTF printing based on this data, you can enhance profitability and tailor your offerings to meet market demand.

| Key Point | Details |

|---|---|

| Understanding UV DTF Printing | A modern technique for high-quality printing on various materials using UV light for durability. |

| Regular Printer Maintenance | Maintain printers to prevent downtime. Regular cleaning of print heads and checking ink flow are crucial. |

| Invest in Quality Materials | Use high-quality films and inks to enhance print vibrancy and customer satisfaction. |

| Proper Calibration of Equipment | Calibrate printers for accurate color reproduction to avoid misalignments and reprints. |

| Analyze Cost Effectiveness | Regular cost analysis helps in identifying areas of waste and optimizing pricing. |

| Focus on Target Markets | Target niche markets like custom apparel and promotional materials for profitability. |

| Effective Marketing Strategies | Utilize social media and online marketplaces to reach more customers and showcase your products. |

| Streamline Your Workflow | Automate processes and minimize waste for improved efficiency. |

| Embrace Data Analytics | Leverage technology to analyze sales data and improve product offerings. |

| Continuous Education and Training | Stay updated with trends and technology through workshops and networking. |

Summary

To optimize UV DTF printing is to adopt a holistic approach that combines efficiency, quality, and strategic marketing. Implementing regular maintenance on printing equipment ensures uninterrupted production and high-quality outputs. Investing in quality materials enhances customer satisfaction and reduces reprints due to poor quality. Additionally, proper calibration of printers and a focus on targeted markets can greatly influence profitability. Effective marketing strategies, streamlined workflows, and embracing data analytics are vital for staying competitive. Finally, continuous education keeps your skills sharp and your operations adaptable to industry changes. By integrating these strategies, your print shop can maximize profits and maintain a strong position in the competitive printing landscape.