Industrial-Grade DTF supplies: Essentials for Pro Shops

Industrial-Grade DTF supplies form the backbone of a productive, professional print shop, delivering reliability when high-volume orders roll in. For shops that demand durable transfers, choosing the right DTF printing supplies ensures color fidelity, repeatable results, and satisfied clients. This guide helps you recognize the signs of quality, from stable DTF inks and uniform DTF films to efficient transfer powders and dependable heat press for DTF performance. Industrial-grade components extend equipment life, reduce waste, and keep throughput high through consistent color and adhesion. By building a reliable workflow around these supplies, shops stay competitive while meeting tight deadlines.

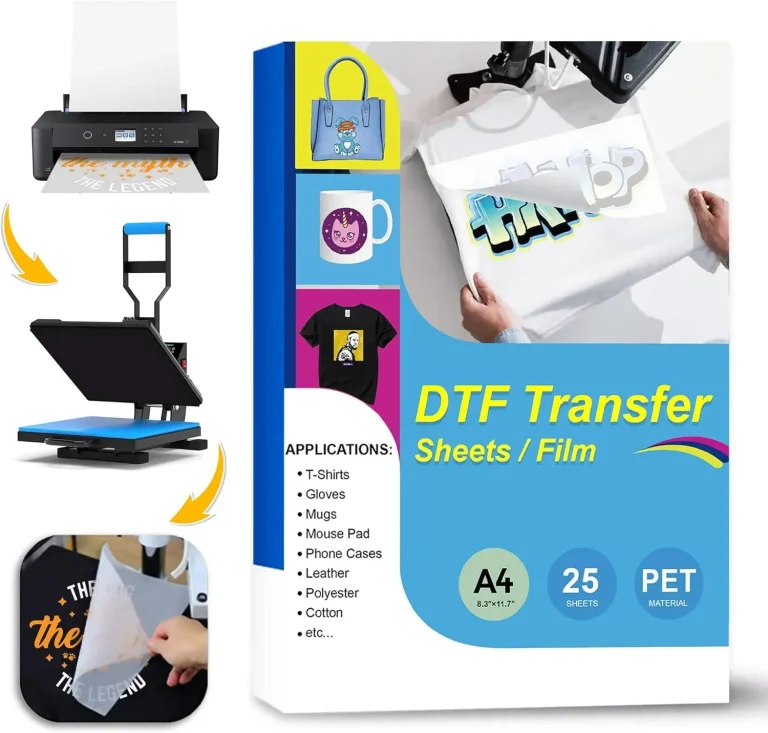

Viewed through a different lens, professional-grade DTF materials form a complete production toolkit for textile customization. When printers, films, powders, and heat-press equipment are designed to work together, manufacturers achieve reliable throughput, vibrant color, and durable finishes, key objectives of DTF production. These professional DTF consumables, also known as direct-to-film production components, include DTF inks, DTF films, transfer powders, and heat-press solutions optimized for scalable workflows. Framing the topic with related terms like transfer media, digital textile printing, and color-management friendly workflows helps align search intent with the broader world of industrial- and pro-shop-grade printing supplies.

Industrial-Grade DTF supplies: A foundation for scalable, high-throughput pro-shop production

Industrial-Grade DTF supplies are the backbone of any successful professional print shop. For shops that handle high-volume transfers, choosing industrial-grade components boosts throughput, color fidelity, and long-term durability. When evaluating DTF printing supplies, priorities include robust ink performance, film uniformity, and transfer powders formulated for even coverage across a range of fabrics. This approach minimizes bottlenecks and ensures repeatable results on substrates from cotton and blends to dark fabrics.

A cohesive workflow anchored by reliable DTF inks, quality DTF films, and well-formulated transfer powders reduces waste and downtime. Incorporating a dependable heat press for DTF with uniform temperature and consistent pressure further strengthens consistency across batches, supporting fast turnarounds without sacrificing quality. In short, industrial-grade DTF supplies enable pro shops to scale operations while maintaining tight control over color, adhesion, and durability.

Optimizing DTF production: From inks to heat press for DTF and films

Optimizing DTF production starts with selecting the right combination of DTF inks, DTF films, and transfer powders to achieve strong adhesion, vibrant color, and reliable wash-fastness. Industrial-grade inks should offer stable nozzle performance, a wide color gamut, and proper rheology for consistent output across multiple prints. Pairing these inks with compatible DTF films—carefully chosen for thickness, release properties, and edge handling—helps prevent banding and ghosting during long runs.

A well-structured workflow also depends on precise heat-press parameters and good post-processing practices. A heat press for DTF that delivers uniform platen temperature, accurate timing, and stable pressure minimizes variability between logs and large orders. Couple this with rigorous color management, pre-treatment when needed, and systematic quality checks to ensure films, powders, and inks work harmoniously, delivering durable transfers that stand up to repeated washing and wear.

Frequently Asked Questions

What are the key benefits of Industrial-Grade DTF supplies for high-volume production, and how do DTF inks, DTF films, transfer powders, and a heat press for DTF contribute to consistency and durability?

Using Industrial-Grade DTF supplies in a professional shop delivers repeatable results, reduced downtime, and scalable throughput. DTF inks are designed for stable nozzle performance, wide color gamut, and fast curing; DTF films provide uniform thickness, reliable release, and low defect rates for long runs; transfer powders offer even coverage and strong adhesion with minimal residue; a heat press for DTF delivers uniform temperature, precise time, and consistent pressure across the platen. Together, these components support high-volume production on cotton, blends, and dark fabrics, yielding durable transfers that withstand washing.

How can a professional shop select and validate an Industrial-Grade DTF supplies bundle to ensure color accuracy and adhesion across substrates?

Start with compatibility and batch traceability: ensure inks, films, and powders are designed to work with your printer and substrate portfolio. Evaluate DTF inks for color gamut, viscosity, curing, and wash-fastness; assess DTF films for thickness uniformity, release properties, and feed stability; review transfer powders for uniform coverage, low dust, and wash resistance. Test with dedicated color profiles and swatches, verify heat-press performance with programmable presets, and implement a simple QC workflow. A cohesive, well-supported Industrial-Grade DTF supplies kit minimizes variability across fabrics such as cotton, blends, and dark garments and drives consistent adhesion and color.

| Aspect | Key Points |

|---|---|

| Value of Industrial-Grade DTF Supplies |

|

| DTF Inks |

|

| DTF Films |

|

| Transfer Powders and Adhesives |

|

| Heat Presses and Workflow Precision |

|

| Substrates and Ink Interaction |

|

| Setting Up a Pro-Shop-Ready DTF Workflow |

|

| Quality Control and Troubleshooting |

|

| Best Practices for Pro Shops |

|

| Common Mistakes to Avoid |

|

| A Practical Buying Guide for Pro Shops |

|

Summary

Industrial-Grade DTF supplies empower pro shops to deliver consistent, high-quality transfers at scale. By selecting reliable inks, robust films, and well-formulated transfer powders, and by implementing a precise heat-press workflow, you can build a production line that meets demand while maintaining top-tier print quality. A disciplined workflow with strong quality control minimizes variability, reduces waste, and improves color fidelity across a broad range of fabrics. Choosing compatible, well-supported components and maintaining rigorous maintenance practices future-proofs your operation and helps grow your business.