How to Create Stunning DTF Transfers: A Step-by-Step Guide

Creating custom apparel has never been easier, especially when mastering how to create stunning DTF transfers. This innovative method of Direct to Film printing allows designers to produce vibrant, detailed designs that can be seamlessly transferred onto various fabrics using a heat press DTF technique. In this comprehensive tutorial, we will guide you through each step of the DTF printing process, equipping you with the essential knowledge on how to make DTF transfers that stand out. Whether you’re a beginner aiming to create beautiful DTF prints or an experienced creator looking to refine your skills, our DTF transfers tutorial will help you achieve professional results every time. From preparing your designs to applying the final touches, this guide answers all your burning questions about DTF printing steps.

Direct to Film transfers, frequently referred to as DTF printing, is revolutionizing the way we approach custom garment design. This technique stands out due to its ability to generate vibrant designs that can be applied to various textiles, ensuring an array of creative possibilities for fashion enthusiasts and professionals. By utilizing a specialized printing process and heat application, anyone can learn how to create these striking fabric prints. In this article, we will explore the DTF process and provide actionable insights into achieving impressive results, making it a fantastic starting point for anyone eager to dive into the world of custom apparel creation. Embrace the potential of DTF printing as we unravel the steps needed to create unforgettable designs.

Introduction to DTF Transfers: What You Need to Know

Direct to Film (DTF) transfers have revolutionized the world of custom printing, providing a sophisticated solution for creating vibrant and detailed designs that stand out on various fabrics. This printing technology uses a specialized film to achieve a higher level of detail and color saturation, making it an essential tool for both amateur and professional creators alike. With a DTF transfer, your creations can go from digital designs to tangible products that capture attention, ensuring your custom apparel reflects your unique style.

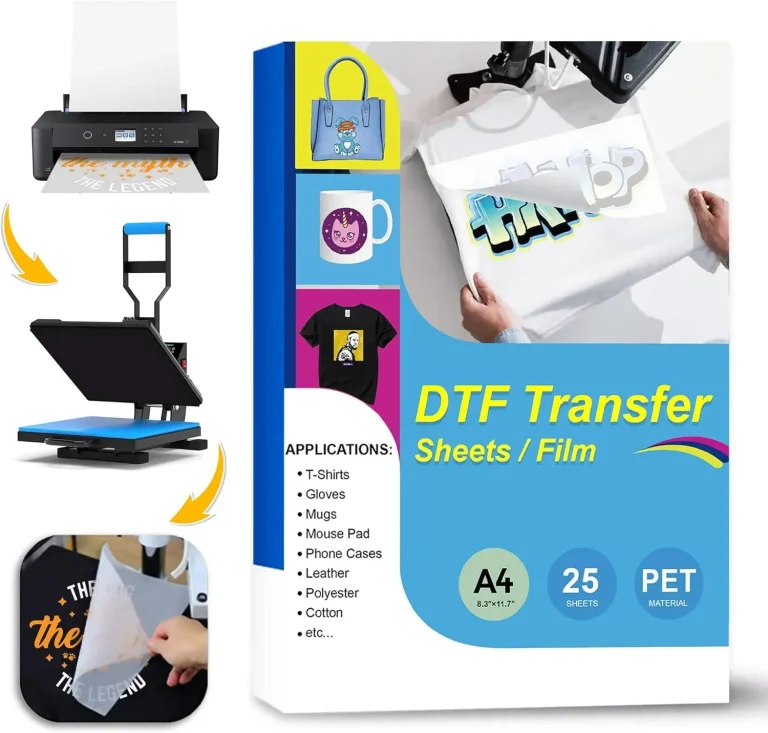

Moreover, the versatility of DTF transfers makes them suitable for a wide range of applications, from t-shirts to hoodies, and even accessories like bags and caps. They are particularly advantageous for small batch production since the setup does not require extensive equipment and can be done quickly compared to traditional screen printing methods. In addition, DTF transfers offer an incredible opportunity for personalization, allowing you to create one-of-a-kind items that appeal to a diverse audience.

How to Create Stunning DTF Transfers in 7 Easy Steps

If you’re eager to explore how to create stunning DTF transfers, the process can be broken down into seven manageable steps. Starting with designing your artwork, you will use software capable of producing high-resolution images to ensure clarity and vibrancy in your final prints. Following that, selecting the right materials is imperative; this includes choosing the appropriate DTF printer, inks, and film suited for your specific design needs.

The next step involves printing your chosen design onto the DTF film, after which you’ll apply adhesive powder for proper adhesion to fabric. This is followed by curing the print to ensure the adhesive binds correctly. Prepping your fabric is essential, necessitating thorough cleaning and pre-pressing to prevent any moisture-related issues. Finally, the heat press application will seal your design into the fabric, resulting in high-quality, vibrant prints that last.

Essential Tools for DTF Printing Success

To successfully create DTF transfers, having the right tools and materials at your disposal is crucial. Essential tools include a reliable DTF printer, which is specialized to handle the unique needs of DTF film and inks. Your choice of printer can significantly influence the quality of your transfers, so investing in a model known for its reliability can pay off in the long run.

Additionally, strong quality control measures for inks and films are necessary. You will need specific DTF inks, which offer compatibility with your printer and ensure the longevity of your designs. A heat press is another critical component, as it provides the consistent temperature and pressure required for perfect adhesion of the transfer to the fabric. Collectively, these tools enhance your DTF printing experience, leading to beautiful and durable results every time.

DTF Printing Steps: Detailed Breakdown

Understanding the DTF printing steps can help streamline your process for greater efficiency and results. Begin by preparing your design and ensuring it meets high-resolution standards. This ensures that your final output reflects the details and vibrancy of your original artwork. Moving on to selecting your materials, ensure you choose high-quality DTF inks and films that complement your design and desired fabric.

As you proceed to print your designs onto the film, you’re setting the stage for successful DTF transfers. Pay close attention to printer settings, as these can alter the way colors appear. After curing and applying the adhesive powder, direct heat must be applied with precision during the heat press stage, as this is vital for achieving a quality transfer that adheres correctly to your fabric, ensuring longevity and durability.

Troubleshooting Common DTF Transfer Issues

While the DTF transfer process is relatively straightforward, challenges may arise that could hinder your results. Common issues include designs not appearing vibrant enough, which can often be remedied by ensuring high-quality inks and proper printer settings are utilized. Colors might not show accurately if the calibration of your printer is off or if the film quality is subpar.

Another frequent challenge is transfers not adhering properly during heat pressing, which can result from incorrect temperature or pressure settings. Ensuring you follow recommended guidelines for curing and transferring your designs will mitigate many of these issues. Continually refining your process as you become familiar with common pitfalls will lead to better and more satisfying outcomes.

Final Thoughts on Creating Beautiful DTF Prints

In conclusion, mastering the art of DTF printing offers an exciting way to unleash creativity and showcase individuality through custom apparel. The process, while structured, also invites innovation as you experiment with different designs, fabrics, and techniques to find what works best for your projects. As you refine your skills, you will soon be able to create stunning DTF transfers that not only display your artistic vision but also stand the test of time.

As you embark on this DTF journey, remember the importance of practice and experimentation. Each printing session is an opportunity to learn and enhance your technique further. With the right tools, knowledge, and creativity, DTF printing can become a rewarding endeavor, opening doors to endless possibilities in personalized fashion and design.

Frequently Asked Questions

How to create stunning DTF transfers for custom apparel?

To create stunning DTF transfers, start by preparing a high-resolution design using software like Adobe Illustrator. Then, choose quality DTF inks and film, print your design, apply hot-melt adhesive powder, and cure the print in a heat source. Finally, heat press the transfer onto your fabric to achieve beautiful, vibrant designs.

What are the steps in a DTF transfers tutorial?

In a DTF transfers tutorial, you follow these steps: prepare your design, select the right inks and materials, print your design onto DTF film, apply adhesive powder, cure the print, prepare your fabric, and heat press the transfer. This process ensures stunning results on various garments.

What materials do I need to make DTF transfers?

To make DTF transfers, you’ll need a DTF printer, compatible DTF inks, high-quality DTF transfer film, hot-melt adhesive powder, and a heat press machine. These materials are essential for creating beautiful DTF prints with vibrant colors that last.

Can I use a regular printer to create beautiful DTF prints?

No, to create beautiful DTF prints, it’s essential to use a dedicated DTF printer designed for this type of transfer method. Regular printers will not provide the necessary quality and adherence for effective DTF printing.

What is the heat press DTF technique and how is it used?

The heat press DTF technique involves applying heat and pressure to transfer your printed design from the DTF film to the fabric. This method solidifies the adhesive powder, ensuring the transfer adheres well and results in a stunning, durable print.

How to troubleshoot common issues when making DTF transfers?

To troubleshoot DTF transfers, check if your design is printed with high-quality inks and settings. If transfers are not adhering, ensure enough heat and pressure are applied during the heat press phase. For fading colors, confirm you are using the correct fabric and DTF inks.

| Key Steps | Description |

|---|---|

| Step 1: Prepare Your Design | Design your artwork using high-resolution software like Adobe Illustrator. Consider colors and sizing for optimal results. |

| Step 2: Choose the Right Inks and Materials | Select a DTF printer, compatible DTF inks, and high-quality DTF film to ensure success. |

| Step 3: Print Your Design | Load DTF film into your printer, optimize settings, and allow prints to dry. |

| Step 4: Apply Adhesive Powder | Apply a hot-melt adhesive powder evenly for proper adherence to fabric. |

| Step 5: Cure the Print | Preheat your curing oven and melt the adhesive powder for 30-60 seconds. |

| Step 6: Prepare the Fabric | Ensure the fabric is clean and pre-press to eliminate moisture. |

| Step 7: Heat Press the Transfer | Align the transfer on the fabric, cover it, and heat press for 10-15 seconds. |

Summary

How to Create Stunning DTF Transfers is a detailed guide that empowers you to craft custom apparel with captivating designs. This method is rapidly becoming a favorite among creators for its ability to produce high-quality prints with longevity. By meticulously following each step—from preparing your design and selecting the right materials to expertly applying your graphics—you can achieve professional-quality results that make your custom pieces stand out. Furthermore, understanding troubleshooting tips ensures that you can enhance your technique and continue improving your skills. Embrace your creativity and explore the exciting realm of DTF printing for unique, durable, and visually striking garments.