Georgia DTF: Ultimate Guide to Direct to Film Printing

Georgia DTF is redefining how local shops approach custom apparel by combining modern digital printing with the efficiency of Direct to Film processes. In practice, DTF printing Georgia delivers vibrant colors and detailed imagery on a variety of fabrics, from cotton tees to blends. For Georgia Direct to Film workflows, the technology supports on-demand production, smaller runs, and quicker turnarounds for teams, schools, and brands. Choosing between DTF transfers and DTG, or weighing DTF vs DTG, often comes down to fabric type, cost, and scalability, with DTF transfers offering flexibility for low-volume orders. To keep projects smooth, teams in Georgia should also consider Direct to Film supplies Georgia when selecting films, powders, and heat presses.

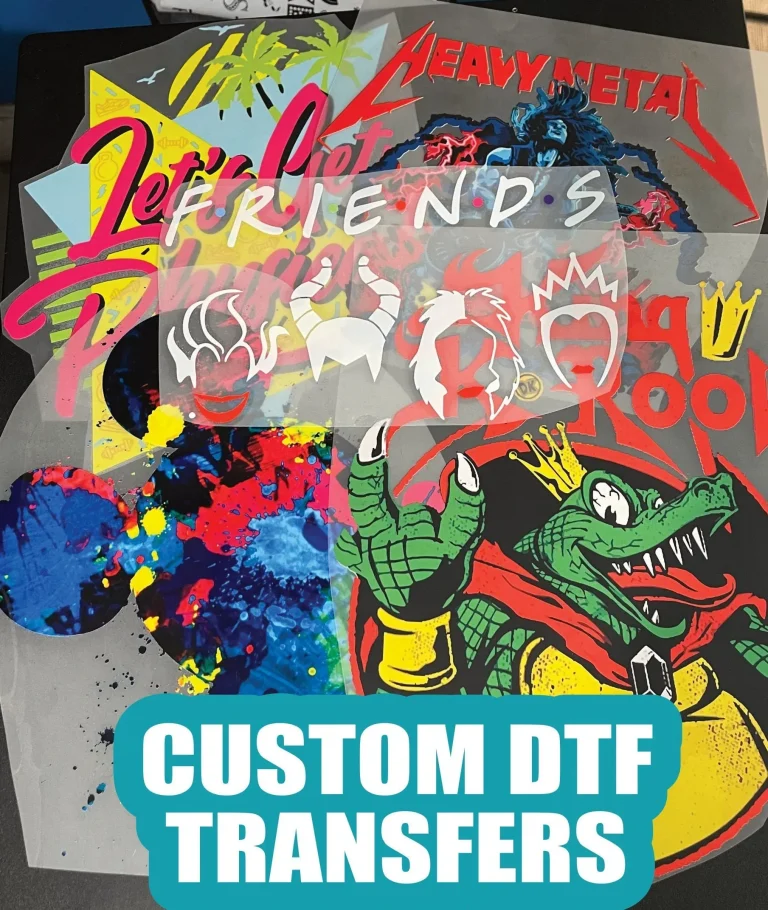

In other words, the film-based Direct to Film approach lets designers embed intricate artwork into a transfer sheet that can be applied to apparel through heat and pressure. This Peach State–friendly printing method supports on-demand manufacturing, quick design testing, and easy customization for teams, schools, and brands across Georgia. Users can compare this technology to traditional methods like screen printing by focusing on durability, color fidelity, and production flexibility, which are central to DTF transfers. For suppliers and shops, sourcing the right film, powder, and heat-press setup in Georgia ensures consistent results without large minimums.

What is Georgia DTF?

Georgia DTF stands for Direct to Film printing within the Georgia market, blending digital design with a transfer sheet and a heat-activated finish. This approach delivers vibrant color, fine detail, and the flexibility of on-demand production, making it a practical option for Georgia-based brands, teams, and events. It aligns with the DTF printing Georgia landscape by leveraging local resources and regional capabilities to streamline workflows.

As a locally framed term, Georgia DTF emphasizes proximity to suppliers and service networks, helping shops source Direct to Film supplies Georgia and shorten lead times. For startups and small shops, this locality translates into lower upfront costs, faster prototyping, and the ability to expand SKUs without committing to large-volume presses.

DTF printing Georgia: From Design to Transfer

DTF printing Georgia workflows begin with design preparation, color management, and print-ready settings tailored for transfer sheets used in the Direct to Film process. In Georgia, printers also consider substrate types common to the region to optimize color accuracy and transfer performance.

The design is then printed onto a clear PET transfer film with a DTF printer that can lay down a white underbase for light fabrics and full color for dark fabrics. A fine adhesive powder is applied, the film is cured, and the transfer is placed on the garment and heat-pressed. The Georgia Direct to Film environment often emphasizes local calibration and fabric compatibility to ensure consistent results.

DTF vs DTG in Georgia: Choosing the Right Method

When deciding between DTF and DTG, Georgia shops weigh image fidelity on dark fabrics, substrate compatibility, and cost per unit. DTF tends to offer sharper color and better transferability across a wider range of fabrics, which makes it attractive for Georgia fashion and sportswear applications.

DTG can deliver excellent results on cotton and lighter garments but may require pretreatment and can be less effective on dark fabrics without additional steps. In Georgia, many printers use a hybrid approach, leveraging DTF for flexibility and speed while reserving DTG for higher-volume cotton runs. This balance helps local businesses adapt to seasonal demand and regional tastes.

DTF transfers: Quality and Outcomes for Georgia Markets

DTF transfers aim for a soft hand feel, wash durability, and bright, precise colors that resist cracking or fading after repeated cycles. In Georgia markets, customers expect prints that withstand the region’s laundry patterns and weather, keeping imagery sharp through regular wear.

To achieve strong DTF transfers in Georgia, it’s important to partner with reputable film, powder, and ink suppliers and to invest in a quality heat press and proper curing equipment. Consistent results come from matched components, careful calibration, and routine process checks across batches.

Direct to Film supplies Georgia: Tools and Setup

The Georgia DTF toolkit includes DTF printers with white ink capability, compatible transfer films, adhesive powders, curing devices, heat presses, and a steady supply of garment blanks. Local distributors can provide service plans tailored to Georgia studios, supporting uptime and performance.

Choosing the right Direct to Film supplies Georgia depends on budget, expected volume, and target fabrics. Working with regional suppliers simplifies maintenance and access to compatible inks and films, helping shops scale while keeping quality consistent across orders.

SEO and Local Marketing for Georgia DTF: Building a Local Brand

To maximize visibility, structure content around the focus keyword Georgia DTF and related terms such as DTF printing Georgia, Georgia Direct to Film, and DTF transfers. Create region-specific pages and posts that reference Georgia cities, counties, and local events to improve relevance for local searches.

Publish tutorials, case studies, and troubleshooting guides that address real-world Georgia use cases. Build backlinks from local printers, schools, teams, and suppliers, and optimize for fast-loading, mobile-friendly experiences. The goal is to attract Georgia-based interest and convert it into inquiries and orders for DTF transfers.

Frequently Asked Questions

What is Georgia DTF and why should printers consider DTF printing Georgia?

Georgia DTF refers to Direct to Film printing tailored for the Georgia market. It enables on‑demand production with vibrant color and low setup costs, which makes DTF printing Georgia ideal for startups and local shops. By leveraging Georgia Direct to Film workflows, printers can offer faster turnarounds and expand SKU options for Georgia customers.

DTF vs DTG: How does Georgia DTF compare for local shops in Georgia?

DTF transfers typically offer lower per‑unit costs for small runs and work well on a wider range of fabrics, including darks, which suits many Georgia markets. DTG excels on cotton with high-volume runs but may require pretreatment. For many Georgia DTF customers, a hybrid approach—DTF transfers for most fabrics and DTG for select cotton applications—provides the best mix of cost, quality, and flexibility.

What are the essential Direct to Film supplies Georgia shops need to start with Georgia DTF?

Key Direct to Film supplies Georgia shops should have include a DTF printer with white ink capability, PET transfer films, adhesive powders, a curing unit, a reliable heat press, and appropriate garment blanks. Stock spare parts and cleaning supplies, and work with reliable Georgia suppliers to ensure compatibility and service.

What does a typical DTF transfers workflow look like for Georgia DTF?

A typical DTF transfers workflow involves design preparation, printing onto PET film with white ink for light fabrics and color for dark fabrics, applying adhesive powder, curing the powder, transferring the image to the garment with heat and pressure, and a final curing step. Each step should be tuned to the fabrics common in Georgia markets and aligned with Georgia Direct to Film practices.

Where can I source Direct to Film supplies Georgia and get local support for Georgia Direct to Film?

Look for local Georgia Direct to Film distributors and regional suppliers who offer DTF printers, films, powders, and heat presses, plus service plans tailored to Georgia studios. You can also tap into Georgia DTF communities and forums for recommendations on Direct to Film supplies Georgia and nearby support networks.

What SEO strategies boost Georgia DTF content and improve local visibility for DTF printing Georgia?

Focus on regionally relevant terms like Georgia DTF, DTF printing Georgia, and Georgia Direct to Film in titles, headers, and body content. Create Georgia-specific pages or blog posts about local events and partners, and naturally weave related terms such as DTF transfers and DTF vs DTG. Build value with tutorials and case studies from Georgia shops to earn local backlinks and improve mobile, fast-loading experiences.

| Topic | Key Points | Georgia DTF Relevance / Related Keywords |

|---|---|---|

| What is Georgia DTF? | Georgia DTF stands for Direct to Film printing in the Georgia context. Benefits include vibrant color, print-on-demand capability, no screens, faster turnaround times, lower minimums, and more SKUs for local brands. | Georgia DTF, DTF printing Georgia, Georgia Direct to Film, Related: DTF transfers, Direct to Film supplies Georgia |

| DTF printing Georgia workflow | Design prep; print onto PET transfer film (white ink for light fabrics, full color for dark); powder application; cure powder; transfer to fabric with heat/pressure; finish and cure. Local Georgia suppliers and fabric types (cottons, blends) influence settings. | Georgia DTF process, heat-press settings, Georgia suppliers, fabrics common in Georgia |

| Why Georgia DTF matters for locals | Speed and flexibility for prototyping and small runs; design freedom for complex artwork; lower upfront costs; on-demand capabilities for Georgia shops serving local events, schools, teams. | Local business benefits, SEO relevance: Georgia DTF opportunities |

| DTF vs DTG: Georgia considerations | DTF offers strong color on various substrates and is cost-effective for small runs; DTG excels on cotton but may need pretreatment. In Georgia, many shops blend approaches for flexibility and volume. | DTF vs DTG, color fidelity, substrate range, Georgia market adaptation |

| DTF transfers in Georgia | Focus on durable hand feel, wash durability, bright colors, and batch-to-batch consistency. Work with reputable suppliers and proper heat pressing and curing. | DTF transfers, Georgia market expectations |

| Supplies and equipment in Georgia | DTF printers with white ink capability; transfer films; adhesive powders; curing equipment; heat presses; garment blanks. Use regional distributors and service plans. | Georgia DTF supplies, Georgia printers, Georgia heat presses |

| Best practices for Georgia DTF success | Choose substrates (start with 100% cotton and blends), calibrate color for Georgia audiences, test on different fabrics, maintain equipment, provide care instructions to customers, and optimize SEO with Georgia-focused content. | Georgia DTF best practices, local SEO tips |

| Practical SEO moves for Georgia DTF content | Local optimization with Georgia cities/counties; place focus keyword Georgia DTF in titles/descriptions; weave related terms (DTF printing Georgia, Georgia Direct to Film, DTF transfers, DTF vs DTG) naturally; publish tutorials and case studies; ensure fast UX. | Georgia DTF SEO, local optimization, content strategy |

| Common pitfalls and troubleshooting | Ink/film mismatches, temperature/time misalignment, overprinting on dark fabrics, improper handling after transfer. Follow manufacturer settings and test carefully. | DTF troubleshooting, Georgia production issues |

| Real-world examples (hypothetical) | A Georgia shop shifts from screen printing to DTF transfers for small jerseys; a boutique in Atlanta uses region-wide DTF for on-demand designs; a Georgia school district adopts DTF for rapid, multi-campus gear. | Georgia market scenarios, local case studies |