Essential DTF Supplies: Boost Your Printing Business Today

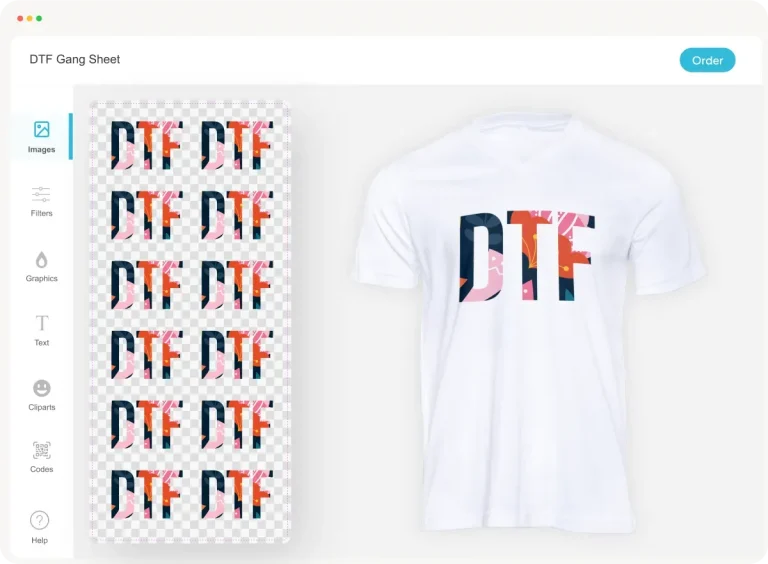

Essential DTF supplies play a crucial role in elevating the capabilities of your printing business in the pressing landscape of DTF printing. As this innovative technology rapidly gains traction, the need for quality components, such as a reliable DTF printer, premium PET film, specialized DTF inks, and effective powder adhesives, becomes more apparent. Each of these supplies contributes to achieving vibrant, high-quality prints that can withstand the test of time. By investing in the right DTF supplies, you can enhance operational efficiency and ensure customer satisfaction, ultimately boosting your profitability. In this article, we will guide you through the must-have supplies that can transform your DTF printing endeavors into a thriving venture.

In the burgeoning field of direct-to-film printing, having the right tools and materials on hand is essential for success. From the high-performance DTF printer required to produce stunning designs, to the versatile PET film and durable printing inks, every element contributes significantly to the overall print quality. Furthermore, utilizing refined powder adhesives enhances the adhesion of prints, making them more resilient. This exploration of necessary tools and materials will provide a comprehensive look into what is needed to optimize your operations in this exciting print technology. Understanding these fundamentals will empower entrepreneurs in the DTF domain to thrive in a competitive market.

The Importance of High-Quality DTF Printers

Investing in a high-quality DTF printer is non-negotiable for businesses aiming to deliver exceptional printing results. DTF printers are specifically engineered to produce vibrant prints that adhere seamlessly to various fabric types. Brands like Epson and Mimaki lead the market with their technologically advanced printers, which incorporate unique features tailored to enhance DTF printing processes. When selected properly, these printers can dramatically reduce waste and improve color accuracy, ensuring your prints stand out in a competitive market.

Furthermore, high-quality DTF printers are not just about print output; they significantly influence the workflows within a printing business. Reliable machines reduce downtime and maintenance efforts, allowing businesses to focus on scaling operations and meeting customer demands. Upgrading to sophisticated models equipped with optimized ink management systems can result in cost savings and increased productivity, ultimately pushing your printing business towards greater profitability.

Understanding PET Film in DTF Printing

**PET film** plays a crucial role in the DTF printing process as it serves as the foundation upon which your vibrant designs come to life. The right type of PET film ensures excellent adhesion of DTF inks, producing prints that maintain their brightness and detail even after numerous washes. The technology behind PET films allows them to withstand heat and pressure from heat presses without deforming or losing graphic integrity, making them indispensable for quality outputs.

Additionally, the choice of PET film directly correlates with the overall quality of the final printed product. Businesses should prioritize sourcing films that meet industry standards, as inferior options could lead to poor ink transfer and compromised print durability. By focusing on high-quality PET films, printing operations can enhance their output quality and customer satisfaction, resulting in a strong reputation in the DTF printing market.

Choosing the Right DTF Inks for Quality Prints

**DTF inks** are the heartbeat of any DTF printing operation, determining not only the vibrancy of prints but also their longevity. When selecting DTF inks, it is vital to choose formulations that are designed specifically for this technology, as they typically contain water-based components. Such inks offer better color quality and wash resilience, ensuring prints retain their brilliance even after repeated laundering.

Moreover, staying updated with the latest ink innovations can significantly benefit your business. As ink formulations evolve to incorporate advanced color gamuts and enhanced adhesion properties, aligning your supply chain with reputable ink suppliers can provide you with a competitive edge. The right DTF inks not only enhance product quality but also expand your market reach by enabling you to offer a broader range of services and applications.

Quality Powder Adhesives for Stronger Transfers

**Powder adhesives** are a vital part of the DTF printing process, ensuring that your beautiful prints adhere properly to fabrics. High-quality hot melt powder adhesives are particularly effective, as they provide consistency and durability in the transfer process. When applied correctly, these adhesives create a strong bond that withstands the test of time, giving your products a significant advantage in terms of quality and longevity.

Choosing the right powder adhesive is crucial, as the wrong type can lead to failures in the transfer process, resulting in disappointing results for both you and your customers. It’s advisable to select adhesives that have been tested for performance under various conditions. By using reliable powder adhesives, businesses can significantly improve the quality of their finished products, thereby enhancing customer satisfaction and fostering repeat business.

Essential Tools for a Successful DTF Printing Setup

In addition to high-quality supplies like printers, inks, and films, having the right tools is essential for an efficient DTF printing setup. A robust heat press, for example, is necessary for achieving optimal adhesion of prints to fabrics. Models that allow for customizable temperature and pressure settings provide better results as they cater to various materials and adhesive requirements, ensuring that the transfers are not only successful but also of high quality.

Moreover, investing in accessories such as cleaning kits and maintenance tools for your DTF printer can extend the life and performance of your equipment. Effective maintenance tools not only reduce downtime but also ensure that your prints remain at the highest quality. As a printing business owner, equipping yourself with the necessary tools is a proactive strategy to improve overall operational efficiency and output quality.

Staying Informed on DTF Market Trends

The DTF printing industry is constantly evolving, and staying informed about the latest market trends is crucial for business success. As demand grows, printing businesses are diversifying their applications, tapping into markets beyond traditional textiles. This shift means that suppliers now need to be equipped with a range of DTF supplies suitable for various substrates, from hard surfaces to flexible materials.

Regularly researching industry publications, attending trade shows, and engaging with peer networks can provide insights into emerging trends and innovative products. By aligning your supply inventory with market demands, you can position your business as a leader in the ever-changing landscape of DTF printing. Staying adaptable and informed ensures that you not only meet current consumer needs but also anticipate future ones.

Frequently Asked Questions

What are the essential DTF supplies for successful printing?

The essential DTF supplies for successful printing include a high-quality DTF printer, PET film for printing designs, specialized DTF inks, powder adhesives for ensuring print adhesion, and a professional heat press. Each of these components plays a critical role in achieving vibrant and durable prints.

How important is PET film in DTF printing?

PET film is crucial in DTF printing as it serves as the printing medium. High-quality PET films ensure excellent ink adhesion and vibrant colors, which remain intact after the transfer process. Investing in reliable PET film from trusted suppliers is essential for optimal print quality.

What should I know about DTF inks for my printing business?

When selecting DTF inks, it’s important to choose specialized, water-based formulations designed for DTF printing. These inks provide vibrant colors and long-lasting durability, making them essential for high-quality prints that withstand washing and wear.

Why are powder adhesives necessary in DTF printing?

Powder adhesives are necessary in DTF printing because they ensure that prints adhere properly to garments. High-quality hot melt powder adhesives enhance the durability of your prints, allowing them to withstand multiple washes, which is vital for customer satisfaction and repeat business.

What kind of heat press is best for DTF printing?

The best heat press for DTF printing should have adjustable temperature and pressure settings to achieve optimal transfer results. A reliable heat press helps ensure proper adhesion and contributes significantly to the overall quality of the final product.

Where can I find quality DTF supplies?

Quality DTF supplies can be found through online resources like Sublimation101 and OWA, which offer comprehensive guides and reliable suppliers for DTF printers, PET film, DTF inks, powder adhesives, and heat presses. Partnering with established distributors can enhance your printing business.

| Key Points | Details |

|---|---|

| Understanding DTF Printing | DTF printing allows designs to be printed on film for transfer to fabrics, offering vibrant colors and durability. |

| Essential DTF Supplies | 1. DTF Printer: High-quality printers from brands like Epson and Mimaki ensure excellent print quality. 2. PET Film: Essential film that allows for vibrant ink adherence. 3. DTF Inks: Water-based inks designed for durability and color quality. 4. Powder Adhesives: Ensure prints adhere well and withstand washing. 5. Heat Press: Professional presses are crucial for quality transfer. |

| Supplier Resources | Websites like Sublimation101 and OWA offer guidance on selecting quality supplies. |

| Training Resources | Online tutorials and workshops (e.g., on YouTube) help in mastering DTF technology. |

| Networking Opportunities | Events like Printing United Expo are valuable for discovering innovations and networking. |

| Recent Market Developments | Businesses are diversifying DTF prints to hard surfaces, increasing demand for quality supplies. |

Summary

Essential DTF Supplies are crucial for printing businesses aiming to leverage the advantages of Direct-to-Film technology. As the demand for high-quality prints in various industries grows, understanding and investing in essential supplies like DTF printers, PET films, specialized inks, and professional heat presses becomes imperative. Quality materials ensure vibrant, durable outputs that meet customer expectations and market trends. By utilizing reputable suppliers and staying informed through training and industry events, businesses can enhance their capabilities, ensuring long-term success in the evolving printing landscape.