DTF vs. Traditional Printing: Which is Right for You?

When diving into the world of custom apparel printing, the debate of DTF vs. traditional printing is at the forefront of many business decisions. Direct to Film (DTF) printing has quickly gained traction as a modern alternative, offering a vibrant and detailed reproduction of designs that attracts many brands looking for efficiency. In contrast, traditional methods like screen printing boast their own set of advantages, particularly in durability and cost-effectiveness for large orders. This comprehensive comparison between DTF and traditional printing will explore the benefits of each method, offering insights into screen printing advantages and the various printing methods comparison for different project needs. Ultimately, understanding the DTF printing benefits as they stack against traditional options empowers you to make the right choice for your printing projects.

In the realm of garment printing, the juxtaposition of DTF and conventional printing techniques often arises when businesses seek the most effective solution for their needs. Modern solutions such as Direct to Film (DTF) provide an innovative approach to applying graphics, whereas age-old methods like screen printing still hold significant sway due to their operational efficiencies and reliability in producing bulk items. This discussion will unravel the nuances of DTF versus traditional printing methodologies, shedding light on the specific merits inherent in each process. Whether you lean towards the intricate possibilities offered by DTF or the tried-and-true capabilities of traditional screen printing, recognizing the right fit for your creative ambitions is essential. As the landscape of custom apparel printing evolves, understanding these diverse approaches ensures you can capitalize on the best options available.

The Benefits of DTF Printing for Custom Apparel

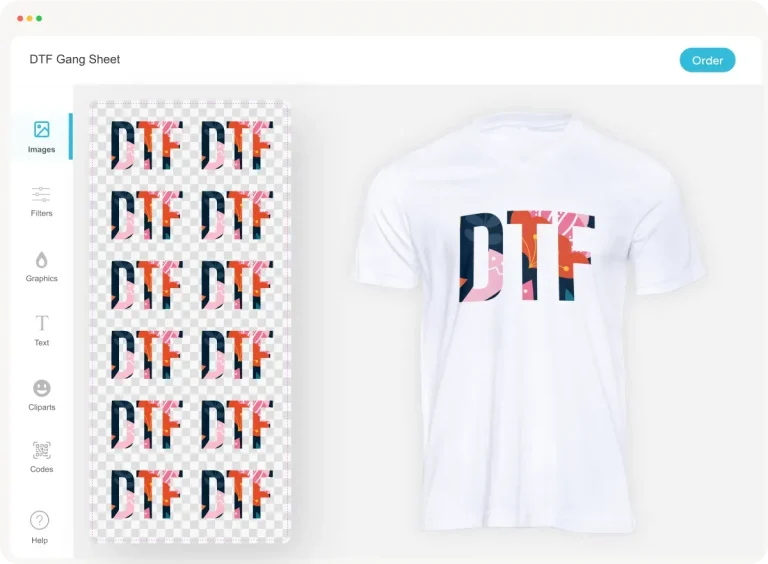

DTF printing offers numerous benefits for custom apparel that make it an attractive choice for various businesses. Firstly, the technology enables high-quality prints with sharp details and vibrant colors, which is essential for designs that demand visual impact. Whether you are producing intricate graphics or a mix of colors, DTF printing ensures that the end product meets creative expectations. Additionally, DTF’s compatibility with a range of fabric types allows for versatility, catering to clothing made of cotton, polyester, or blends without compromising on quality.

Another significant advantage of DTF printing lies in its cost-effectiveness for smaller runs. Unlike traditional methods that often require a substantial upfront investment and are more suited for large batches, DTF allows small businesses to produce customized apparel with low startup costs. With the general trend leaning towards personalization and on-demand printing, DTF serves as a catalyst for startups seeking to make their mark in the custom apparel industry.

Screen Printing Advantages for Bulk Production

Screen printing remains a dominant choice for bulk production due to its reliability and efficiency. This traditional printing method excels in producing large quantities of apparel with consistent colors and quality. Once the screens are set up, the printing process becomes incredibly swift, allowing for significant time savings on high-volume orders. Businesses that focus on large-scale promotional items or seasonal apparel find screen printing to be an effective solution, as it delivers a seamless and cost-effective way to meet high demand.

Moreover, the durability of screen-printed designs is a noteworthy aspect that solidifies its place in the industry. Screen printing is known for producing prints that withstand washes and wear over time, making it ideal for items intended for frequent use, like uniforms or branded merchandise. Companies often rely on these durable prints for customer satisfaction, ensuring that their branded clothing remains vibrant and intact after numerous cycles in the laundry.

DTF vs. Screen Printing: Key Comparisons

When considering DTF vs. screen printing, it’s essential to analyze the key differences that dictate their suitability for various projects. DTF printing shines in scenarios where design intricacy and color variety are prioritized. This method supports detailed artwork and large color palettes without the need for multiple screens, which can significantly speed up the production process for complex designs. On the other hand, screen printing is preferred for solid color designs and large volumes, providing a straightforward production flow that emphasizes efficiency!

In terms of cost, while DTF offers advantages for smaller orders with lower setup expenses, the unit cost of screen printing decreases substantially with larger quantities. Thus, businesses should consider their order volume and design specifications when making a decision. Each method has its strengths—DTF for customized, detailed designs in small batches, and screen printing for robust, lasting prints suited to bulk production.

Ease of Use: DTF vs. Traditional Methods

Ease of use is a crucial factor when selecting a printing method, and DTF printing stands out by being remarkably user-friendly. The process allows for quick modifications to digital designs, catering to dynamic customer demands without requiring extensive adjustments to setup. This is especially beneficial for businesses that operate on short turnaround times or need to adapt rapidly to market trends. DTF technology enables businesses to maintain flexibility in their production schedule, accommodating last-minute changes with minimal hassle.

In contrast, traditional methods like screen printing can pose challenges regarding setup complexity. The requirement for creating screens and stencils can be labor-intensive, often deterring smaller operations or enterprising individuals from choosing this method. Although screen printing results in high-quality output, the meticulous preparation can limit its responsiveness to immediate customer requests or smaller batch sizes.

The Environmental Impact of DTF Printing

The environmental impact of printing methods has become a significant consideration in determining the most responsible choices. DTF printing, with its reduced water consumption compared to traditional methods, such as screen printing, addresses this growing concern effectively. It utilizes eco-friendly inks and minimizes the waste typically associated with water-intensive printing processes. As consumers become more environmentally conscious, brands that adopt DTF printing may find increased favor among audiences prioritizing sustainability.

In contrast, some traditional printing methods can involve higher water usage and chemical consumption, raising questions about ecological sustainability. With increasing regulatory pressures and consumer demand for greener practices, businesses focusing on sustainability may need to evaluate their printing choices thoroughly. Balancing effectiveness and eco-consciousness will be critical for companies looking to meet the standards of today’s environmentally aware market.

Cost Efficiency in Printing: DTF vs. Traditional Methods

Cost efficiency is a critical aspect to consider when choosing between printing methods, especially for new businesses or startups. DTF printing shines due to its lower initial setup costs, making it accessible for those looking to produce custom apparel in smaller quantities. This flexibility allows entrepreneurs to minimize their financial risk while still offering high-quality products tailored to their customer base. As market trends shift towards personalized goods, DTF presents a practical approach for capitalizing on this demand without substantial financial commitments.

Alternatively, traditional methods, particularly screen printing, can be significantly more economical for organizations managing bulk production. While the setup costs are higher, the per-unit price ratio becomes much more favorable as the volume increases, making this approach ideal for established brands engaging in large-scale promotions or merchandising campaigns. Consequently, businesses must assess their specific needs—whether flexibility or volume efficiency is the priority—to determine the most cost-effective printing method for their operations.

Frequently Asked Questions

What are the main advantages of DTF printing compared to traditional methods?

DTF printing offers several benefits over traditional methods like screen printing. It provides vibrant color reproduction and excellent detail for complex designs, making it ideal for custom apparel printing. Additionally, DTF has lower setup costs and allows for on-demand printing, giving businesses flexibility for small order sizes.

How does DTF vs. traditional printing compare in terms of durability?

Traditional printing methods, particularly screen printing, are well-known for their durability on heavier fabrics. However, DTF printing also offers long-lasting quality, with prints that resist fading when cared for properly. Ultimately, both methods have distinct advantages in durability depending on the material used.

When should I choose DTF vs. screen printing for my custom apparel?

Choosing DTF vs. screen printing depends on your order volume and design complexity. DTF is better suited for smaller runs and intricate designs, while screen printing shines with larger orders due to its cost-effectiveness and efficiency in production.

What are the environmental impacts of DTF printing compared to traditional printing?

DTF printing tends to have a lower environmental impact compared to traditional methods, using less water and often employing eco-friendly inks. In contrast, traditional printing methods like screen printing can consume more water and chemicals, raising sustainability concerns.

Can I achieve vibrant colors with traditional printing methods like screen printing?

Yes, screen printing can produce vibrant colors, especially for solid color designs. However, for highly detailed graphics and a broader color range, DTF printing generally provides superior results due to its digital nature and advanced technology.

Is DTF printing more cost-effective than screen printing for small businesses?

Yes, DTF printing is often more cost-effective for small businesses, particularly for small runs. It has lower setup costs and allows for quick adjustments, making it accessible for startups. Screen printing becomes more economical at larger volumes due to the decreasing per-unit costs.

| Aspect | DTF Printing | Traditional Printing |

|---|---|---|

| Quality | Vibrant color reproduction and clarity, ideal for complex designs. | Known for durability and solid colors, especially on heavier fabrics. |

| Cost-Effectiveness | Lower setup costs; great for small runs. | Higher initial costs but lower per-unit cost for large orders. |

| Ease of Use | User-friendly and quick for digital adjustments. | Requires lengthy setup, more manual labor involved. |

| Environmental Considerations | Uses less water and eco-friendly inks. | Greater water use and chemicals, raising environmental concerns. |

Summary

DTF vs. Traditional Printing is a crucial consideration for anyone involved in custom printing. While DTF printing stands out due to its vibrancy, cost-effectiveness for small runs, and eco-friendliness, traditional printing remains a robust option known for its durability and cost efficiency in high volumes. Understanding the differences between these two printing techniques allows businesses and individuals to choose the method that best aligns with their project needs and sustainability goals.