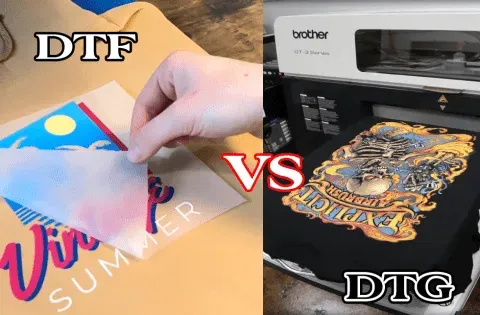

DTF vs. DTG: Which Method is Superior for Custom Printing?

When assessing your options for custom printing, the comparison of DTF vs. DTG stands out as a pivotal discussion point for many businesses in the apparel industry. With Direct-to-Film (DTF) printing offering a unique approach that transfers vibrant designs onto fabric through a specialized film, it presents a compelling alternative to Direct-to-Garment (DTG) printing, which uses inkjet technology to achieve intricate, detailed prints directly on the fabric. This printing technology comparison highlights critical differences in versatility, production speed, and print quality. DTF advantages, such as its ability to work with multiple fabric types, make it highly appealing for brands seeking to diversify their product offerings. Understanding these two custom printing methods will better equip you to choose the right solution for your specific needs.

In the realm of fabric printing, the distinctions between direct-to-film and direct-to-garment methods are crucial for professionals and enthusiasts alike. These innovative custom printing techniques allow for varying degrees of design complexity and material compatibility, catering to diverse customer demands. The direct-to-film approach excels in rapidly producing vibrant and durable prints across a wide range of textiles, while direct-to-garment focuses on delivering exceptional detail for complex graphics that seamlessly integrate into the fabric. As new advancements surface within these printing technologies, understanding their unique attributes becomes essential for optimizing production processes and product offerings. By exploring these alternative terms, businesses can make informed decisions that enhance their custom printing strategies.

Exploring the Benefits of Direct-to-Film (DTF) Printing

Direct-to-Film (DTF) printing has gained popularity as a versatile printing method suitable for a wide array of fabric types. This technique enables businesses to create vibrant, high-quality prints that can be applied to cotton, polyester, and even unique fabric blends. The ability to print on such a diverse range of materials makes DTF an appealing choice for custom printing ventures, allowing companies to broaden their product offerings. Furthermore, the color vibrancy achieved through DTF technology is particularly advantageous for designs featuring gradients or detailed imagery. This capability enhances customers’ visual experience, ultimately leading to increased satisfaction and repeat business.

In addition to its versatility in fabric types, DTF printing offers notable cost benefits for smaller businesses. The initial setup costs associated with entering the DTF market are often lower compared to other printing methods. This affordability opens the door for aspiring entrepreneurs to explore custom printing without hefty financial burdens. Moreover, after the setup phase, DTF’s streamlined processes can lead to faster production times, resulting in improved turnaround and higher profit margins. Consequently, DTF serves as an ideal solution for businesses looking to optimize their operations while maintaining quality standards.

Decoding the Advantages of Direct-to-Garment (DTG) Printing

Direct-to-Garment (DTG) printing is renowned for producing high-quality prints with exceptional detail. This method leverages advanced inkjet technology, allowing for the direct application of ink onto the fabric fibers. The result is a soft feel that integrates seamlessly with the material, providing a premium experience for the end user. Such intricacy makes DTG especially suitable for complex designs, where multiple colors and gradients are needed to bring artistic visions to life. For businesses focused on detailed artwork, DTG stands out as a top-tier printing solution.

However, the advantages of DTG are coupled with specific requirements that can influence a business’s decision-making process. Notably, DTG printing necessitates pre-treatment of fabrics to ensure optimal ink absorption, which can potentially prolong production time. Additionally, DTG printing is limited to certain fabric types, primarily those made from cotton or cotton blends. Despite these challenges, the quality and feel of DTG prints appeal significantly to niche markets seeking bespoke, high-fidelity designs.

DTF vs. DTG: Key Factors in Your Selection Process

When deciding between DTF and DTG, it’s crucial to weigh factors such as material compatibility, design complexity, and production efficiency. DTF shines with its wide applicability across different fabric types, making it ideal for businesses looking to offer a diverse range of products. In contrast, DTG excels in producing intricate designs with unmatched detail but may require the use of cotton or similar materials to achieve the desired quality. Therefore, analyzing your target materials and desired aesthetics will influence which method best aligns with your objectives.

Furthermore, you should consider the production timeline. DTF printing’s capacity for faster production times post-setup makes it attractive for businesses with tight turnaround requirements. On the other hand, DTG’s pre-treatment phase may extend its overall processing time, particularly if the designs are complex and require meticulous attention. By evaluating your operational goals and customer demands, you can make a more informed choice that optimizes efficiency and quality.

Comparative Analysis of Recent Technological Advancements in DTF and DTG

Recent advancements in DTF and DTG technologies have brought new possibilities for custom printing businesses. For instance, the latest machinery launched by Brother supports both DTF and DTG options, indicating a shift towards flexible solutions that cater to diverse printing needs. These innovations facilitate hybrid approaches, allowing businesses to leverage the strengths of both methods. As a result, companies can effectively diversify their offerings and meet varying customer demands, ultimately enhancing their competitive edge in the market.

Moreover, the introduction of Sawgrass’s VersiFlex technology signifies a substantial leap for DTF and DTG processes. This new technology permits printing on multiple substrates without requiring pre-treatments, streamlining workflow and increasing efficiency. By adopting such advancements, businesses can minimize operational costs while maximizing output quality. Staying abreast of these technological developments ensures that companies can remain agile and responsive to market trends, positioning themselves strategically in the ever-evolving custom printing landscape.

Weighing the Pros and Cons of DTF and DTG Printing

Both DTF and DTG printing technologies come with distinct advantages and drawbacks, necessitating a thorough examination before making a decision. DTF printing boasts significant pros, including its versatility across a range of fabric types and lower start-up costs for small businesses. These factors make it a robust choice for entrepreneurs entering the custom printing market. However, potential durability concerns may arise, particularly after multiple washes, which businesses need to consider when evaluating long-term customer satisfaction.

On the other hand, DTG printing offers remarkable quality and a soft feel, ideal for complex designs. The intricacies it can achieve in print detail attract businesses focusing on artistic and bespoke products. However, the pre-treatment requirements and material limitations could pose challenges, impacting production times and costs. Businesses must balance these pros and cons against their specific operational needs and target markets to select the most suitable printing method.

The Future of Custom Printing: Navigating DTF and DTG Choices

As custom printing technologies evolve, businesses need to continuously reassess their approach to DTF vs. DTG methods. With innovations launching regularly, including hybrid solutions that combine the strengths of both DTF and DTG, the landscape of custom printing is rapidly changing. Companies that embrace this evolution stand to benefit from improved efficiencies and broader product ranges, allowing them to cater to an increasingly diverse clientele.

In this dynamic environment, it’s essential for businesses to stay informed about new technologies and market trends affecting custom printing methods. Networking at industry events, such as Fespa 2025, can provide valuable insights into advancements that may shape future printing strategies. By adapting to these changes and understanding the capabilities of DTF and DTG, businesses can not only remain competitive but also offer superior products that meet the diverse needs of their customers.

Frequently Asked Questions

What are the key differences in DTF vs. DTG printing methods?

The main difference between DTF (Direct-to-Film) and DTG (Direct-to-Garment) printing lies in their application and workflow. DTF allows for versatility in printing on various fabric types, while DTG is primarily suited for specific textiles and produces softer, more detailed prints. Additionally, DTF generally offers quicker turnaround times due to fewer pre-treatment requirements.

What are the advantages of choosing DTF printing for custom apparel?

DTF printing offers several advantages, including its ability to print on a wide range of fabrics, lower initial costs for businesses, and faster production times after setup. It’s especially beneficial for companies aiming to provide diverse custom printing options without extensive pre-treatment processes.

Can DTG printing accommodate complex designs better than DTF?

Yes, DTG printing excels in producing intricate designs and gradients due to its ability to penetrate fabric fibers with ink. This method ensures high design resolution and a soft finish, making it an excellent choice for detailed artwork compared to DTF, which, while vibrant, may not match DTG’s detail capabilities.

What recent advancements have been made in DTF vs. DTG technology?

Recent advancements in DTF and DTG technology include the launch of hybrid machines that can manage both methods and the introduction of innovations like Sawgrass’s VersiFlex technology. This new technology enables printing on multiple substrates without pre-treatments, enhancing efficiency and flexibility for businesses.

Is DTF printing a more cost-effective option than DTG for small businesses?

DTF printing tends to be more cost-effective for small businesses, particularly due to lower setup costs and less requirement for expensive pre-treatment processes compared to DTG. This affordability allows new entrants to the custom printing market to establish themselves more easily.

How do DTF and DTG printing methods compare in terms of durability?

While both DTF and DTG produce high-quality prints, DTG generally offers better long-term durability after multiple washes, as the ink integrates directly with the fabric. In contrast, DTF prints may exhibit some wear over time, particularly if not properly cared for, making durability an important factor when choosing between the two.

| Feature | DTF (Direct-to-Film) | DTG (Direct-to-Garment) |

|---|---|---|

| Application Variety | Prints on various fabric materials. | Generally limited to specific fabric types. |

| Production Time | Faster turnaround times due to streamlined processes. | Longer due to pre-treatment requirements. |

| Print Feel and Complexity | Excels in color vibrancy; can handle detailed designs. | Soft finish with better integration for complex designs. |

| Pros | Versatile, cost-efficient, faster production after setup. | High-quality, soft prints, ideal for intricate designs. |

| Cons | Durability may be less after multiple washes. | Requires pre-treatment; limited to specific fabrics. |

| Recent Technologies | Hybrid machines emerging, combining strengths of both methods. | Advancements reducing pre-treatments for greater efficiency. |

Summary

In considering DTF vs. DTG, it’s essential to weigh the unique advantages of each method against your specific custom printing needs. DTF is well-known for its versatility and cost efficiency, making it ideal for businesses looking to expand their product offerings across various fabrics. On the other hand, DTG is revered for its superior detail and soft print feel, catering to high-quality designs specifically suited for compatible material types. Recent advancements in printing technology are facilitating a convergence of these methods, allowing businesses to harness the best of both worlds. This dynamic landscape means that understanding the key differences and specific applications is crucial for your success in the custom printing market.