DTF vs. DTG: Understanding Differences in Printing

In the evolving landscape of custom apparel printing, the debate over DTF vs. DTG has gained significant traction among enthusiasts and professionals alike. Both Direct to Garment (DTG) and Direct to Film (DTF) printing techniques offer unique benefits, making it essential to understand their differences. As businesses shift toward personalized prints, discerning which method aligns best with their needs becomes crucial for quality and efficiency. This article aims to provide a comprehensive comparison, highlighting each process’s strengths, disadvantages, and ideal applications in the world of custom apparel printing. By the end, you’ll have a clear understanding of the best printing method for t-shirts and other garments to help you make an informed decision about your printing projects.

When considering the advancements in fabric printing technology, a comparison between DTF and DTG—also known as Direct to Film and Direct to Garment—reveals distinct characteristics that set these methods apart. Both techniques focus on delivering vibrant and durable designs for clothing, yet each has its own unique processes and applications. Understanding these alternate terminologies allows individuals and businesses to better navigate their options in the realm of personalized apparel. This exploration will delve into the attributes and outcomes of DTF and DTG printing, offering insights on how these methods cater to varying requirements in custom garment production. By examining their differences and advantages, we can uncover which approach might be the ideal fit for your specific printing needs.

Understanding Direct to Garment (DTG) Printing Process

Direct to Garment (DTG) printing has revolutionized the custom apparel industry by allowing intricate designs to be printed directly onto garments. This digital printing method utilizes high-resolution inkjet technology, allowing for a vast palette of colors and intricate details. The process involves pre-treating the fabric to ensure optimal ink adhesion, followed by the direct application of water-based inks, which soak into the fibers, creating a soft finish that is pleasing to the touch.

One of the standout features of DTG printing is its ability to produce small runs with minimal setup time and no color limitations. This makes it a popular choice for custom t-shirt printing, personalized apparel, and small business branding. Since each garment can be printed independently, designers can create one-of-a-kind pieces or fulfill small orders without the risk of wasted materials, making DTG not only artistically rewarding but also cost-effective for bespoke designs.

Exploring Direct to Film (DTF) Printing Advantages

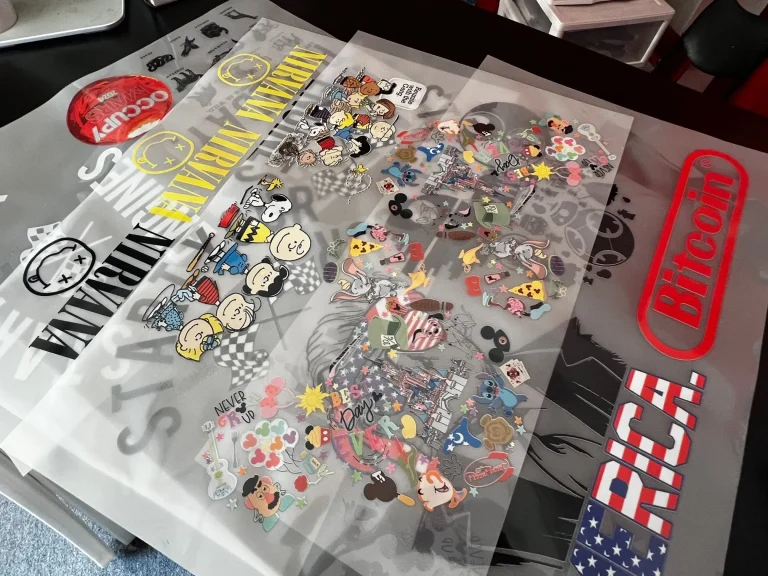

Direct to Film (DTF) printing employs a unique technique that transfers designs from a specially coated film to various fabrics using a heat press. This method has gained traction due to its flexibility and efficiency, especially for bulk orders. Unlike DTG, which is limited to certain fabric types, DTF can effectively print on cotton, polyester, and even mixed fibers, making it a versatile choice for custom apparel printing.

DTF printing is especially beneficial for businesses seeking to cater to a wide demographic. The prints created through DTF techniques are not just vibrant and detailed; they also exhibit excellent durability, able to endure multiple washes without significant color fading. This ensures that clothing maintains brand quality over time, making DTF a preferred option for those who prioritize longevity and performance in their printed fabrics.

DTF vs. DTG: Comparing Printing Techniques

When evaluating DTF vs. DTG, one must consider several critical factors defining each method’s efficiency and suitability for specific applications. DTG printing is ideal for high-quality designs on cotton fabrics, offering unmatched detail and color vibrancy, making it a go-to method for intricate artworks. In contrast, DTF printing’s capability to operate on various fabric types affords businesses greater flexibility in product offerings.

Moreover, the production efficiency of DTF is notable; it allows for rapid production without the extensive setup that DTG requires, making it easier to handle large orders in a timely manner. The comparison reveals how DTG shines in quality details while DTF excels in versatility and operational speed. This understanding aids businesses and designers in selecting the appropriate printing method based on their specific project requirements.

Material Compatibility: DTG vs. DTF

Material compatibility is a substantial element when distinguishing between DTF and DTG printing methods. DTG is predominantly suited to 100% cotton garments and cotton blends, which benefit from its precise ink application and soft feel. However, this limitation might restrict designers and brands when exploring various fabric options for their custom apparel. DTG is often less effective on synthetic fabrics, which might lead to challenges in achieving the desired quality.

On the other hand, DTF brings forth a remarkable advantage with its compatibility across a wider range of materials including polyester, cotton, and blends. This characteristic makes DTF printing an optimal choice for businesses that aim to diversify their product lines beyond just cotton t-shirts. Understanding these material interactions ensures that businesses can effectively meet market demands and satisfy customer preferences for varied fabric types.

Cost Analysis: DTF vs. DTG Printing Methods

Cost is a decisive factor when choosing between DTF vs. DTG, with each method offering unique financial advantages depending on the scale of the order. DTG’s setup can be costly for small prints, as each design requires individual configuration and pre-treatment. For smaller businesses or bespoke items, this may lead to higher per-piece costs, making DTG less appealing for mass production.

Conversely, DTF printing tends to provide a more economical solution for larger orders due to its ability to print multiple designs on a single roll of film, minimizing material waste and setup time. This cost-effectiveness, coupled with its expansive material compatibility, positions DTF as a favorable choice for businesses looking to balance quality and profitability in their custom printing endeavors.

Best Printing Method for T-Shirts: DTG or DTF?

Choosing the best printing method for t-shirts ultimately relies on the specific needs of the project and the desired outcome. For businesses focused on high-quality, detailed designs primarily on natural fabrics, DTG is often the preferred choice due to its superior color reproduction and finish. DTG is particularly well-suited for one-off designs or small batch orders, allowing artists to showcase their work with stunning detail.

However, for brands aiming to cater to a broader audience with diverse fabric offerings, DTF presents a compelling alternative, especially when speed and durability are priorities. The method manages to preserve the vibrancy of prints across various material types, making it ideal for t-shirt printing that demands flexibility and economic efficiency. Thus, understanding the product’s intended usage and design requirements helps businesses determine whether DTG or DTF best aligns with their branding and production goals.

Frequently Asked Questions

What are the main differences between DTF and DTG printing?

When comparing DTF vs. DTG, the primary differences include the printing technique—DTG prints directly onto the fabric, while DTF prints on a special film first. Additionally, DTG is mainly compatible with cotton, whereas DTF can work on various fabrics, making it a versatile option for custom apparel printing.

Which printing method is best for detailed designs: DTF or DTG?

For intricate and detailed designs, Direct to Garment (DTG) printing is often the best choice. DTG provides high-resolution images and vibrant colors, making it ideal for complex artwork compared to Direct to Film (DTF), which is better for bulk orders and material versatility.

Is DTF printing more cost-effective than DTG for bulk orders?

Yes, in terms of printing techniques comparison, DTF tends to be more cost-effective for bulk orders. DTF printing allows multiple designs to be printed on one roll of film and transferred simultaneously, making it quicker and cheaper for larger runs than DTG, which can incur higher costs for individual setups.

Can DTF printing be used on all types of fabrics?

Yes, one of the advantages of Direct to Film (DTF) printing is its versatility. It can print on a wide range of fabrics including cotton, polyester, and blends, catering to various customer needs, unlike Direct to Garment (DTG), which primarily works best on cotton.

What is the durability comparison between DTF and DTG prints?

When discussing durability in DTF vs. DTG printing, DTF prints typically have superior durability and can withstand numerous washes without significant fading. In contrast, DTG prints, while visually striking, may fade more quickly if not cared for properly.

Which is more eco-friendly, DTF or DTG printing?

In terms of eco-friendliness, Direct to Garment (DTG) printing often uses water-based inks that are less harmful to the environment. However, Direct to Film (DTF) can also be eco-friendly, depending on the inks used. If sustainability is a key concern, DTG is generally regarded as the more eco-friendly option.

| Aspect | DTG (Direct to Garment) | DTF (Direct to Film) |

|---|---|---|

| Printing Technique | Directly prints ink onto the garment. | Prints designs on film before transferring to the fabric. |

| Material Compatibility | Primarily cotton and cotton blends. | Compatible with a range of fabrics including cotton and polyester. |

| Setup Time and Production Speed | Longer setup, not ideal for large orders. | Faster for bulk orders, allows simultaneous transfers. |

| Cost Considerations | Higher costs for small runs due to individual setups. | More cost-effective for large orders. |

| Print Durability | Can fade faster if not cared for properly. | Lasts longer and resists fading over time. |

Summary

In the debate of DTF vs. DTG, it’s important to recognize the specific strengths and suitability of each printing method for custom apparel. DTG printing is renowned for delivering stunning, high-quality designs directly onto cotton fabrics, making it an ideal choice for intricate or vibrant artworks. Conversely, DTF printing offers remarkable versatility in material compatibility and production efficiency, thereby catering to a wider array of fabrics and bulk orders with superior durability. Understanding the essential differences between DTF vs. DTG allows businesses and individuals to choose the most appropriate printing technique that aligns with their design requirements and production goals.