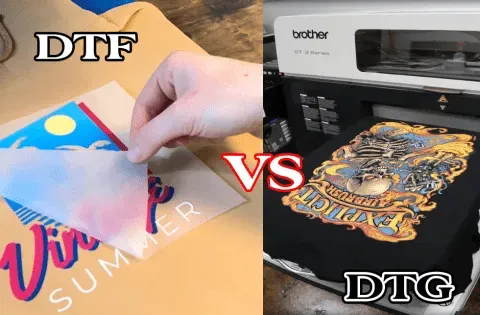

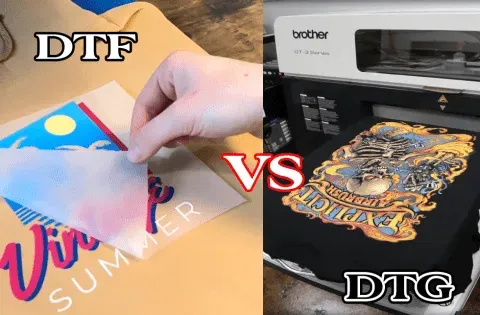

DTF vs DTG: Choosing the Right Printing Method for You

DTF vs DTG printing represents a pivotal choice for those entering the customized printing space. Direct-to-Film (DTF) printing and Direct-to-Garment (DTG) printing are two leading methods that offer distinct benefits and drawbacks, tailoring to different market needs. In an industry where customization and quality are paramount, knowing the printing methods comparison between these two techniques can aid businesses in achieving their desired outcomes. With DTF printing advantages such as versatility across various fabrics and DTG printing disadvantages like limitations on material types, understanding these differences is essential for making informed decisions. This article will guide you through the intricacies of both methods, ensuring you choose the best approach for your printing projects.

When it comes to custom printing options, the debate between Direct-to-Film and Direct-to-Garment printing frequently arises. These printing techniques serve the contemporary market by allowing users to apply vibrant and intricate designs to textiles, making them appealing for various applications. As businesses and designers explore their options, distinguishing between these printing technologies is crucial for optimizing resource allocation and project outcomes. This article aims to elucidate the capabilities and limitations of these two approaches, providing valuable insight into which method aligns best with individual needs.

Understanding the Basics of DTF and DTG Printing

Direct-to-Garment (DTG) printing primarily uses specialized inkjet technology to print images directly onto fabrics, typically cotton. This process allows for high-resolution designs with a wide spectrum of colors, making it suitable for detailed artwork and vibrant images. DTG is particularly effective for small to medium-sized batches since each print is made on-demand, eliminating waste and offering customization for each order.

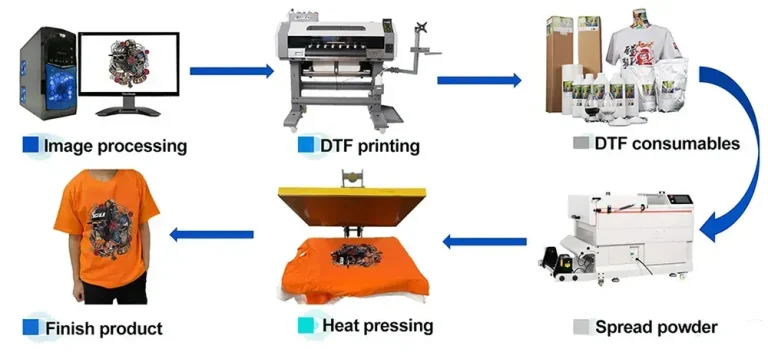

On the other hand, Direct-to-Film (DTF) printing involves creating a transfer film that contains the desired design, which is then heat-pressed onto various fabrics. This approach is not limited to cotton and can work with polyester and cotton blends, enhancing its versatility. As a newer method, DTF is attracting businesses seeking to maximize their printing capabilities across different material types.

DTF vs DTG: Key Differences in Printing Techniques

The primary distinction between DTF and DTG printing lies in their application methods. DTG employs direct inkjet printing onto fabric, which requires a well-prepared surface for optimal adherence and color accuracy. This method excels in producing highly intricate designs but may struggle with fabrics other than pure cotton, limiting its range of applications.

In contrast, DTF printing’s use of a transfer film allows it to be applied to a wider array of materials. The film method not only enhances compatibility with various fabrics but also offers the benefit of sharp and vibrant prints with excellent durability. Thus, businesses looking for a more flexible printing option will find DTF particularly advantageous.

Evaluating Print Quality: DTF vs DTG

When evaluating print quality, DTG is often synonymous with vibrant and detailed output. The high-resolution nature of DTG printing makes it perfect for artwork that requires gradation and subtleties of color. However, despite its impressive capabilities, the longevity of the print can be a concern as colors may fade over time with multiple washes, leading to a need for careful consideration regarding garment care.

DTF printing has made significant strides in achieving comparable quality. Many advancements have allowed DTF prints to maintain their color intensity and clarity after washing. This method’s adaptability not only broadens the options for fabric selection but also ensures that the prints remain robust against wear and tear, giving it an edge in durability when compared to DTG.

Cost Analysis: DTF and DTG Printing

Cost considerations are vital when choosing between DTF and DTG. DTG printing typically incurs higher start-up costs due to the investment in advanced printing equipment and specialty inks. These expenses can make DTG less viable for businesses that aim to start with small production runs or those that are budget-conscious.

DTF printing, in contrast, presents a cost-effective solution as it allows for lower initial investment and reduced costs per print when producing larger quantities of transfer films. This pricing strategy is particularly beneficial for smaller businesses looking to produce various designs without committing to large batches upfront, making DTF an attractive option in today’s competitive market.

Production Efficiency: Comparing DTF and DTG Speed

In the realm of production efficiency, speed plays a crucial role. DTG printing often requires longer processing times, especially when handling larger orders. The complexity of directly applying ink to each garment means that fulfilling urgent requests can be challenging, potentially delaying delivery times for customers needing quick service.

DTF printing provides a notable advantage in speed due to its streamlined process of transferring multiple designs onto a single film sheet. This capability not only accelerates the production cycle but also improves overall workflow efficiency, allowing businesses to meet tight deadlines while maximizing output.

The Future of DTF and DTG Printing: Trends and Innovations

As the custom apparel industry evolves, recent trends indicate a growing preference for DTF printing due to its versatility and cost-efficiency. Many small businesses and online custom shops are embracing DTF technology, drawn by its ability to cater to diverse fabric requirements and its economical production process. This trend reflects a broader movement toward flexibility in printing options amidst rising competition.

Conversely, DTG printing continues to hold its ground for high-quality, intricate designs on cotton garments. Innovations in printer technologies and inks are enhancing the capabilities of DTG, addressing some of the drawbacks associated with durability and washability. As both methods develop, businesses will need to stay informed about advancements in each technique to optimize their offerings and adapt to market demands.

Frequently Asked Questions

What are the key differences between DTF and DTG printing methods?

The main differences between DTF (Direct-to-Film) and DTG (Direct-to-Garment) printing lie in their application processes and fabric compatibility. DTF uses heat transfer from printed films and works on multiple fabric types, including polyester, while DTG prints directly onto garments, primarily suitable for 100% cotton. This affects the level of detail, durability, and versatility associated with each printing method.

What are the advantages of DTF printing compared to DTG printing?

DTF printing offers several advantages over DTG printing, including versatility in fabric choice, cost-efficiency for smaller runs, and quicker production speed. With DTF, businesses can print on diverse materials without compromising print quality, making it an attractive option for those needing flexibility in their product offerings.

Are there any disadvantages of DTG printing I should be aware of?

Yes, DTG printing has some disadvantages, primarily its higher initial costs and slower production speed. It’s also limited to cotton fabrics, and prints may fade over time, especially with frequent washing. These factors can make DTG less ideal for larger, varied production runs compared to the more adaptable DTF printing.

How does the cost of DTF printing compare to DTG printing?

DTF printing generally presents a more budget-friendly option compared to DTG printing. The initial setup cost for DTF is often lower, and it allows for reduced printing costs by producing films in bulk, making it suitable for smaller or varied production runs where DTG may be less economical.

Which printing method is faster: DTF or DTG?

DTF printing is typically faster than DTG printing. DTF can print multiple designs onto a single film sheet, streamlining the application process. In contrast, DTG’s direct printing method can be slower, especially for larger orders, which may lead to longer turnaround times.

What should I consider when deciding between DTF vs DTG for my business?

When deciding between DTF vs DTG, consider factors such as the types of fabrics you’ll use, the complexity of your designs, your budget, and production volume. DTG is ideal for high-quality, detailed designs mainly on cotton, whereas DTF is better for versatility and cost-effective solutions for diverse materials.

| Characteristic | DTG Printing | DTF Printing |

|---|---|---|

| Definition | Direct printing of designs onto garments using inkjet technology | Printing designs on a film that is heat-pressed onto fabric |

| Best Fabric Type | 100% cotton fabrics | Cotton, polyester, and blended fabrics |

| Quality of Prints | High resolution and vibrancy, but potential fading over washes | Good detail quality and durability, retains vibrancy |

| Cost Considerations | Higher initial investment, best for larger orders | Lower setup cost, economical for small runs |

| Production Speed | Slower, particularly for larger orders | Faster due to multiple designs on a single film sheet |

| Current Trends | More suited for high-quality, intricate designs | Growing preference for versatility and cost-effectiveness |

Summary

In the discussion of DTF vs DTG printing, it’s evident that choosing the right method greatly depends on your specific needs. DTG printing is ideal for detailed designs and vibrant colors, primarily on cotton, while DTF offers unmatched versatility across various fabrics and is more cost-effective for smaller production runs. Understanding these differences empowers businesses and entrepreneurs to select the most suitable printing technique for their custom apparel.