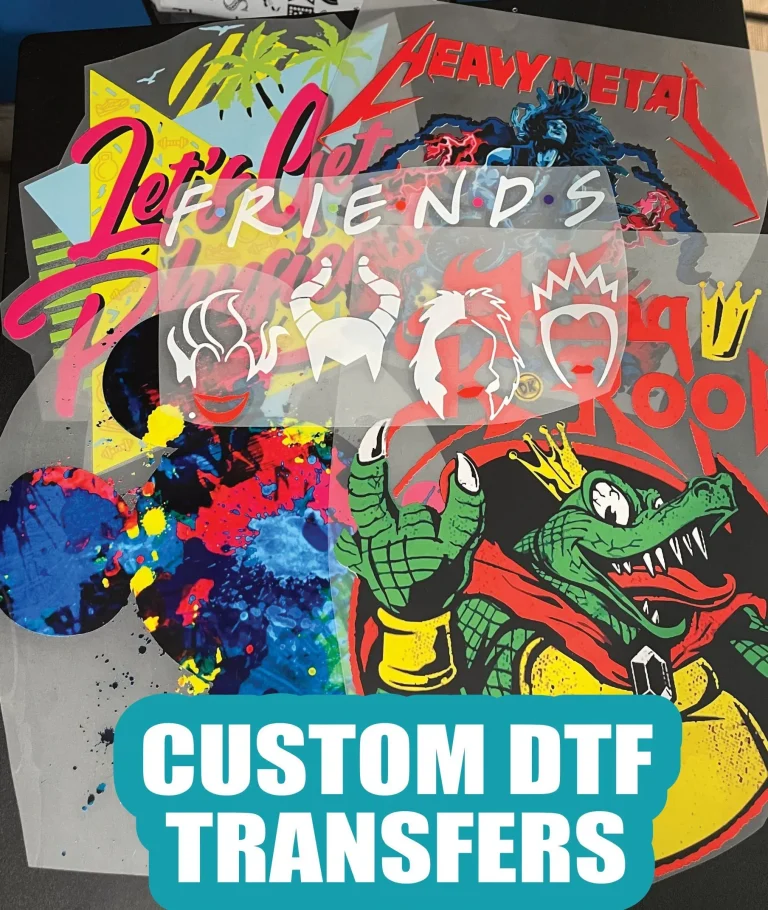

DTF Transfers: Your Ultimate Guide to High-Quality Prints

DTF Transfers, or Direct-to-Film transfers, have revolutionized the world of textile printing by offering a unique method for producing high-quality prints that are both vibrant and durable. This modern printing technique allows for intricate designs to be transferred seamlessly onto a range of fabrics, from cotton to polyester. By utilizing DTF technology, creators can achieve stunning results that stand the test of time, making it an ideal choice for custom apparel and various craft projects. This introductory guide will explore the numerous benefits of DTF printing, including its versatility and ability to deliver vibrant colors. Whether you’re an artist, crafter, or small business owner, understanding DTF Transfers is essential for unlocking the potential of your printing endeavors.

The world of textile printing is rapidly evolving, and at the forefront is Direct-to-Film (DTF) printing, a cutting-edge method that streamlines the transfer of designs onto various fabrics. Known for its capability to produce high-quality prints with remarkable color accuracy, this innovative technique has become a go-to choice for custom garment applications. Many people refer to this process as film transfer printing or simply DTF technology, highlighting its adaptability and the growing trend of personalization in the textile industry. This comprehensive overview will delve into the key aspects of DTF printing, its advantages over traditional methods, and why it stands out in today’s marketplace. From its vibrant print quality to its efficient application on diverse materials, DTF printing is transforming the way we approach textile design.

The Benefits of High-Quality DTF Transfers

DTF transfers bring a wealth of advantages to both artists and businesses looking to produce high-quality prints. For starters, DTF technology offers unparalleled vibrancy, allowing designs to pop on any fabric. This capability stems from the use of specialized inks that maintain their brilliance even after multiple wash cycles. Moreover, the ease and versatility of DTF printing mean that a multitude of textile types, including cotton, polyester, and blends, can be utilized without sacrificing quality. As a result, the DTF printing method caters to various markets, appealing to a diverse range of customers.

Another significant benefit of DTF printing is its cost-effectiveness for smaller projects. Unlike traditional screen printing, which requires extensive setup time and materials for each design, DTF transfers facilitate one-off prints with minimal waste. This feature is particularly appealing to small business owners and independent creators who wish to offer customized apparel without the hefty upfront costs associated with other methods. With such advantages, DTF transfers are becoming essential tools for those looking to produce high-quality textiles effortlessly.

Steps Involved in Creating DTF Transfers

Creating a DTF transfer model involves an organized multi-step process designed to yield vibrant, high-quality prints. Initially, the journey begins with the design phase, where creativity takes flight through graphic design software. It’s crucial during this stage to ensure that the artwork is set to high-resolution settings to guarantee that the final product is as vivid and clear as envisioned. Once the design is completed, it is then printed onto specialized film using a DTF printer, which utilizes high-quality water-based inks that adhere well to a variety of fabric types.

Following the printing stage, the next crucial step is applying the adhesive powder to the still-wet ink on the film. This triumph of DTF technology is what allows for such strong bonds to be formed between the print and the fabric. Afterward, the film is cured to ensure that the adhesive and ink meld perfectly, leading to durable and long-lasting prints once heat pressed onto the designated fabric. This carefully curated process is fundamental to producing high-quality DTF transfers that meet both professional and artistic standards.

Innovations Enhancing DTF Printing

The DTF printing landscape is continuously evolving, with cutting-edge innovations enhancing the overall process. Recently, many companies have increased their investment in modern DTF technology to improve efficiency and quality. For instance, advancements such as large-format DTF printers allow for larger designs and quicker production times, making it ideal for businesses looking to upgrade their offerings. Furthermore, many services now offer custom solutions that cater specifically to the unique needs of crafters and small businesses, providing them with opportunities to differentiate their products in an increasingly competitive market.

Notable players in the DTF industry are also introducing services tailored to meet rapid demand, such as same-day shipping options. This ability to fulfill orders quickly emphasizes the efficiency of DTF technology, enabling creators to work with tighter deadlines without compromising print quality. As these innovations continue to surface, they significantly enhance the appeal of DTF transfers, aligning perfectly with market demands for versatility and swiftness in fulfillment.

DTF Transfers vs. Traditional Methods

When comparing DTF transfers with traditional printing techniques like screen printing and sublimation, there are distinct advantages that DTF offers. Notably, DTF printing is capable of producing vibrant, high-resolution prints on both synthetic and natural fabrics, whereas sublimation is restricted to polyester. This flexibility makes DTF an excellent choice for printers looking to expand their capabilities and explore new materials. Additionally, DTF’s ease of use allows for quicker turnaround times and eliminates the need for extensive setup processes and costly screens, making it accessible for those just entering the industry.

Furthermore, the durability of DTF prints is a significant advantage that can be leveraged when marketing products. DTF transfers resist fading even after numerous washes, ensuring that custom apparel maintains its quality over time. This durability enhances customer satisfaction and encourages repeat business, solidifying DTF’s position as a compelling option for anyone involved in textile printing or apparel design. The ability to create intricate designs with sustained vibrancy positions DTF transfers as a superior option in today’s competitive market.

Educational Resources for Mastering DTF Printing

For individuals eager to dive into the world of DTF printing, numerous educational resources are available to facilitate learning and mastery. Comprehensive guides found on various printing blogs and websites break down the intricacies of the DTF process, offering valuable insights on materials, techniques, and best practices. These resources not only cater to beginners who may feel overwhelmed by the technicalities of DTF transfers but also provide seasoned printers with tips to refine their craft.

Engaging with online communities focused on DTF printing can also yield beneficial knowledge and support. These platforms serve as valuable networks for sharing ideas, troubleshooting challenges, and getting feedback on designs. Moreover, utilizing gang sheets, which involve printing multiple designs on a single sheet, is a strategy that can reduce costs while maximizing design exposure. With these resources at your disposal, mastering DTF transfers can transform into a rewarding journey for both hobbyists and professionals.

The Future of DTF Technology in Textile Printing

The future of DTF technology in textile printing is bright, characterized by continuous advancements and growing market demand. As more businesses recognize the versatility and cost-effectiveness of DTF transfers, they are increasingly adopting this method for their custom printing needs. Innovations are not only improving production speeds but also quality, broadening the range of fabrics and applications for which DTF can be effectively used. These developments indicate that DTF transfers are set to play a pivotal role in the textile printing landscape for years to come.

Moreover, as the DTF market expands, it encourages ongoing research and development into new inks and materials that can further enhance print quality and durability. This forward momentum suggests that artists and businesses will be able to produce ever more intricate designs on a variety of textiles, strengthening their competitive edge in the marketplace. With advancements in technology and a rising trend toward custom apparel, the DTF printing method is poised to become a cornerstone in the future of textile printing.

Frequently Asked Questions

What are the key benefits of using DTF transfers for textile printing?

DTF transfers offer several significant benefits, including versatility across various fabrics, vibrant color reproduction, and high durability. This method supports both synthetic and natural fibers, making it ideal for creating custom apparel with long-lasting prints.

How does the DTF printing process differ from traditional screen printing?

The DTF printing process differs from traditional screen printing in that it does not require screens or large quantities of inks, allowing for more cost-effective small runs. Additionally, DTF works on a wider range of textiles compared to the polyester-restricted screen printing.

What types of fabrics can be used with DTF transfers?

DTF transfers can be used on a variety of fabrics, including cotton, polyester, and blends. This flexibility makes DTF technology a popular choice for custom designs and diverse textile projects.

What innovations are currently shaping the future of DTF technology?

Recent innovations in DTF technology include the introduction of faster production services, such as same-day shipping for orders, and advancements in large-format printing technology, enabling higher quality and efficiency in the DTF transfer process.

Is DTF printing suitable for small businesses looking to create custom apparel?

Yes, DTF printing is highly suitable for small businesses as it allows for low minimum order quantities and high-quality prints, making it accessible for custom apparel projects without large upfront investments.

What resources are available for learning about DTF transfers and printing?

Numerous educational resources exist for learning about DTF transfers, including in-depth online guides, community forums, and tutorial videos that provide valuable insights into best practices and troubleshooting tips for successful DTF printing.

| Key Point | Details |

|---|---|

| Definition of DTF Transfers | DTF transfers involve printing a design onto a special film that is then transferred to fabric using heat. |

| Process Steps | 1. Create a digital design 2. Print on film 3. Apply adhesive 4. Cure the film 5. Heat transfer onto fabric. |

| Recent Innovations | Introduction of new services like those by DTFPrinter.com and Snuggle, along with advancements by Eazydtf to enhance efficiency and capacity. |

| Advantages of DTF | Versatile on various fabrics, vibrant colors, and high durability compared to other methods like screen printing and sublimation. |

| Educational Resources | Numerous guides, community forums, and techniques like gang sheets aid beginners and enhance understanding of DTF printing. |

| Market Growth | The DTF printing market is expanding rapidly, driven by new innovations and increasing investment in technology and services. |

Summary

DTF Transfers offer a revolutionary approach to printing that opens up a myriad of possibilities for creators, businesses, and craft enthusiasts. This innovative method not only allows for high-quality, vibrant prints but also provides unmatched versatility with a wide range of fabrics. As the DTF printing landscape evolves, staying informed about the latest advancements and best practices can position you ahead in the competitive market. Embracing DTF transfers can significantly enhance your creative projects, ensuring that your designs feature prominent colors and durability, crucial for any successful printing endeavor. Whether you are a newcomer or a seasoned professional, delving into the world of DTF transfers promises to elevate your artistry and product offerings.