DTF Transfers: What You Need to Know for Quality Prints

In the ever-evolving landscape of modern printing, DTF transfers have emerged as a game-changing technique, revolutionizing how custom apparel is produced. Leveraging Direct-to-Film printing technology, businesses can achieve high-quality prints that stand out for their vibrancy and detail. The versatility of DTF transfers means they can be applied to an array of fabrics, providing endless possibilities for creativity and design. Furthermore, the benefits of DTF printing include durability and cost-effectiveness, making it an ideal choice for entrepreneurs looking to make a mark in the custom apparel market. As we delve deeper into the world of DTF transfers, discover how they can elevate your printing capabilities while embracing sustainable practices for a better tomorrow.

When talking about innovative printing methods, Direct-to-Film (DTF) technology has gained significant traction in the custom apparel industry. This technique allows for the seamless transfer of designs onto various materials, offering an exceptional blend of quality and efficiency. Many creators are turning to this style of printing due to its ability to produce stunning, long-lasting images, making it possible to cater to diverse customer preferences. Additionally, the trend toward sustainable printing practices aligns perfectly with the rise of DTF transfers, encouraging businesses to adopt more environmentally friendly approaches. Explore the multifaceted advantages that DTF printing has to offer and see how it can transform your apparel production.

Understanding Direct-to-Film (DTF) Printing

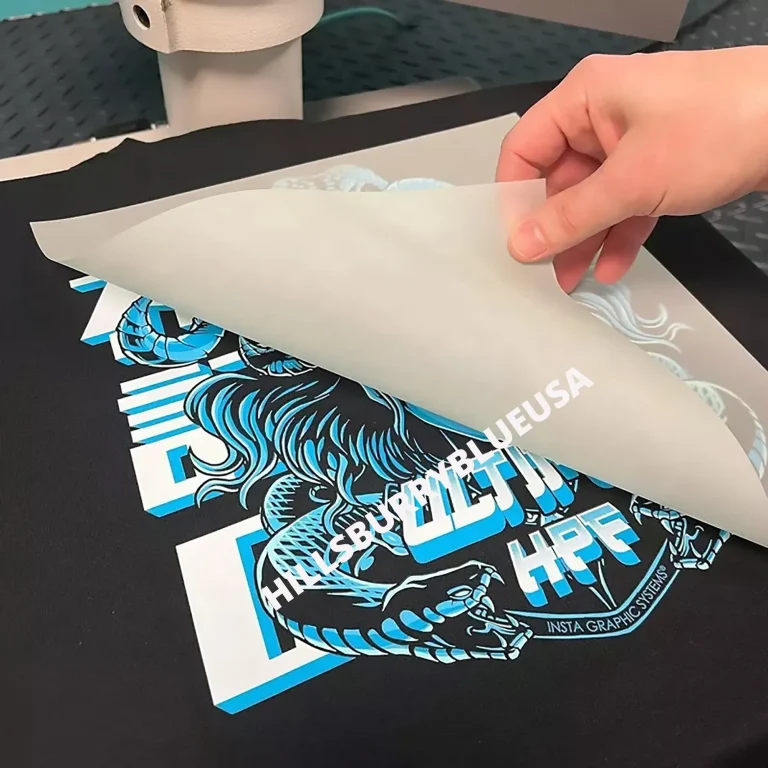

Direct-to-Film (DTF) printing is revolutionizing the way custom apparel is produced. This innovative printing method allows for high-resolution images to be printed on a special film, which can then be transferred onto various fabric types using heat. Unlike traditional printing techniques, DTF ensures that the final product carries vibrant colors and intricate details, making it a preferred option for businesses aiming to provide high-quality prints. With advancements in technology, DTF has become more user-friendly and accessible to operators at all skill levels.

The ease of use associated with DTF printing further enhances its appeal. The process does not require extensive training, allowing for quick adoption in settings ranging from small businesses to larger commercial operations. Additionally, because DTF printing supports a myriad of materials, it opens the door for creative applications beyond standard textiles, such as canvas bags and home textiles, making it a versatile choice for custom apparel creators.

Benefits of DTF Transfers for Custom Apparel

DTF transfers offer numerous benefits for those in the custom apparel business, with one of the most significant being their ability to produce high-quality prints. The durability of DTF prints is unmatched; they resist cracking and fading even after repeated washing, ensuring that garments maintain their aesthetics over time. This resilience not only satisfies customer expectations but also reduces reprint costs, making DTF an attractive option for businesses looking to maximize profitability.

Furthermore, DTF transfers streamline the production process, particularly for small batch orders. Traditional printing methods can often be cost-prohibitive when dealing with limited quantities. However, DTF technology allows for efficient production without the need for extensive setup or waste of materials. This flexibility is ideal for custom designs that require rapid turnaround times and minimizes the risk of surplus inventory, which further supports sustainable printing practices.

The Versatility of DTF Transfers

One of the standout features of DTF transfers is their versatility across a wide range of fabrics. Whether you’re printing on cotton, polyester, blends, or even specialty materials like leather, DTF is capable of delivering exceptional results. This adaptability means that businesses can diversify their product offerings, catering to various customer demands without being limited to a single fabric type.

This versatility extends beyond the choice of materials. DTF printing also allows for customized designs, enabling businesses to tailor products to their clients’ specific needs, from corporate branding to personal gifts. The ability to produce unique graphics on materials traditionally serviced by other printing methods adds significant value and competitive edge in the custom apparel marketplace.

Sustainability in DTF Printing

Sustainability is becoming increasingly crucial in the printing industry, and DTF transfers are well-positioned to align with this movement. The shift towards eco-friendly inks and materials helps to minimize the environmental footprint of custom printing. By utilizing sustainable processes, businesses not only attract environmentally conscious consumers but also contribute positively to the global challenge of reducing waste produced by the textile industry.

Moreover, implementing sustainable practices in DTF printing can enhance brand image and consumer loyalty. As customers become more aware of the environmental impact of their purchases, they tend to gravitate towards brands that prioritize sustainability. By adopting eco-friendly approaches, businesses can set themselves apart from competitors and appeal to a growing niche market that favors sustainable goods.

Technical Considerations for Superior DTF Prints

Achieving superior DTF prints requires careful consideration of several technical factors. Investing in a high-quality DTF printer is crucial for optimal results, as the capabilities of the printer can affect print resolution and vibrancy. Brands like Epson and Roland are renowned for their reliability, and selecting a dependable printer lays the foundation for exceptional print quality.

In addition to choosing the right equipment, operators must also pay close attention to application techniques. Proper heat settings, pressure requirements, and timing are essential for successful application. Each fabric type may require different adjustments, and understanding these nuances can significantly enhance print adhesion and longevity, ensuring that the final product meets high standards of quality.

Future Trends in DTF Printing Technology

The future of DTF printing technology is ripe with potential. Advances in technology promise faster print speeds and improved quality, making DTF transfers even more appealing to businesses. As competition in the apparel market intensifies, companies will likely seek out innovative printing solutions that provide quicker turnarounds without sacrificing quality. This trend will push manufacturers to enhance DTF printer capabilities further, bridging the gap between speed and superior results.

Moreover, the integration of smart technologies in DTF printing operations could streamline workflows, reducing human error and improving efficiency. With the rise of automation and digital tools, businesses might leverage these advancements to simplify their processes, making DTF printing more accessible than ever before. As this technology evolves, it is expected to expand significantly, attracting even more users across various sectors in the printing industry.

Frequently Asked Questions

What are the key benefits of using DTF transfers for custom apparel?

DTF transfers offer numerous benefits for custom apparel producers, including exceptional print quality, versatility across various fabrics, and cost-effectiveness for small runs. The prints are durable and resist fading and peeling, allowing businesses to create high-quality apparel that stands out.

How does DTF printing compare to traditional printing methods?

DTF printing is often more flexible than traditional methods like screen printing. It allows for detailed, high-quality prints with less setup time needed for small batches, making it a cost-effective choice for custom apparel production.

What types of fabrics can DTF transfers be applied to?

DTF transfers are versatile and can be used on a wide range of materials, including cotton, polyester, fabric blends, and even leather. This makes DTF a preferred choice for various custom apparel items.

Is DTF printing a sustainable option for printing?

Yes, DTF printing is moving towards sustainability by utilizing eco-friendly inks and practices. This trend aligns with the increasing demand for sustainable printing solutions among environmentally conscious consumers.

What should I consider when investing in DTF printing equipment?

When investing in DTF printing equipment, focus on the quality of printers and heat presses. Brands like Epson and Roland are known for their reliability, and ensuring you select premium DTF inks will enhance the vibrancy and durability of your prints.

What techniques are crucial for achieving superior DTF prints?

Achieving high-quality DTF prints requires precision in application techniques. Key factors include proper temperature settings, pressure levels, and timing during the heat transfer process, as well as ensuring that the fabric is clean and free from moisture.

| Aspect | Details |

|---|---|

| Introduction | DTF transfers are an innovation in printing used in the custom apparel market, providing high-quality, durable images on various fabrics. |

| What are DTF Transfers? | A process involving printing designs onto a film, which is then heat transferred to fabric, producing vibrant and durable prints. |

| Advantages | – Versatile across fabrics (cotton, polyester, leather) – Exceptional quality with resistance to fading and peeling – Cost-effective for small batches |

| Recent Trends | – Shift to sustainable practices – Technological advancements in speed and quality of printing |

| Key Considerations | – Invest in quality equipment (e.g., printers, heat presses) – Choose the right ink for vibrancy and longevity – Pay attention to application techniques like temperature and pressure settings |

| Challenges | – Higher initial setup costs – Need for skilled operators to manage and maintain equipment |

| Future Outlook | Technological evolution will continue to enhance DTF printing, making it more accessible and efficient in the future. |

Summary

DTF Transfers mark a remarkable breakthrough in the world of printing, particularly within the custom apparel industry. This innovative technique not only excels in producing vibrant, high-quality images on a vast array of fabrics but also offers the durability and versatility businesses need to thrive. As the DTF printing technology advances, it becomes increasingly beneficial for both small and larger production runs, allowing entrepreneurs and companies to deliver outstanding results without breaking the bank. Emphasizing the importance of investing in quality equipment and inks, as well as mastering application techniques, can truly enhance the final product. Looking towards the future, the sustained focus on sustainability and technological advancements suggests that DTF Transfers will continue to play a crucial role in shaping the printing landscape.