DTF Transfers vs. Screen Printing: Which Method Wins?

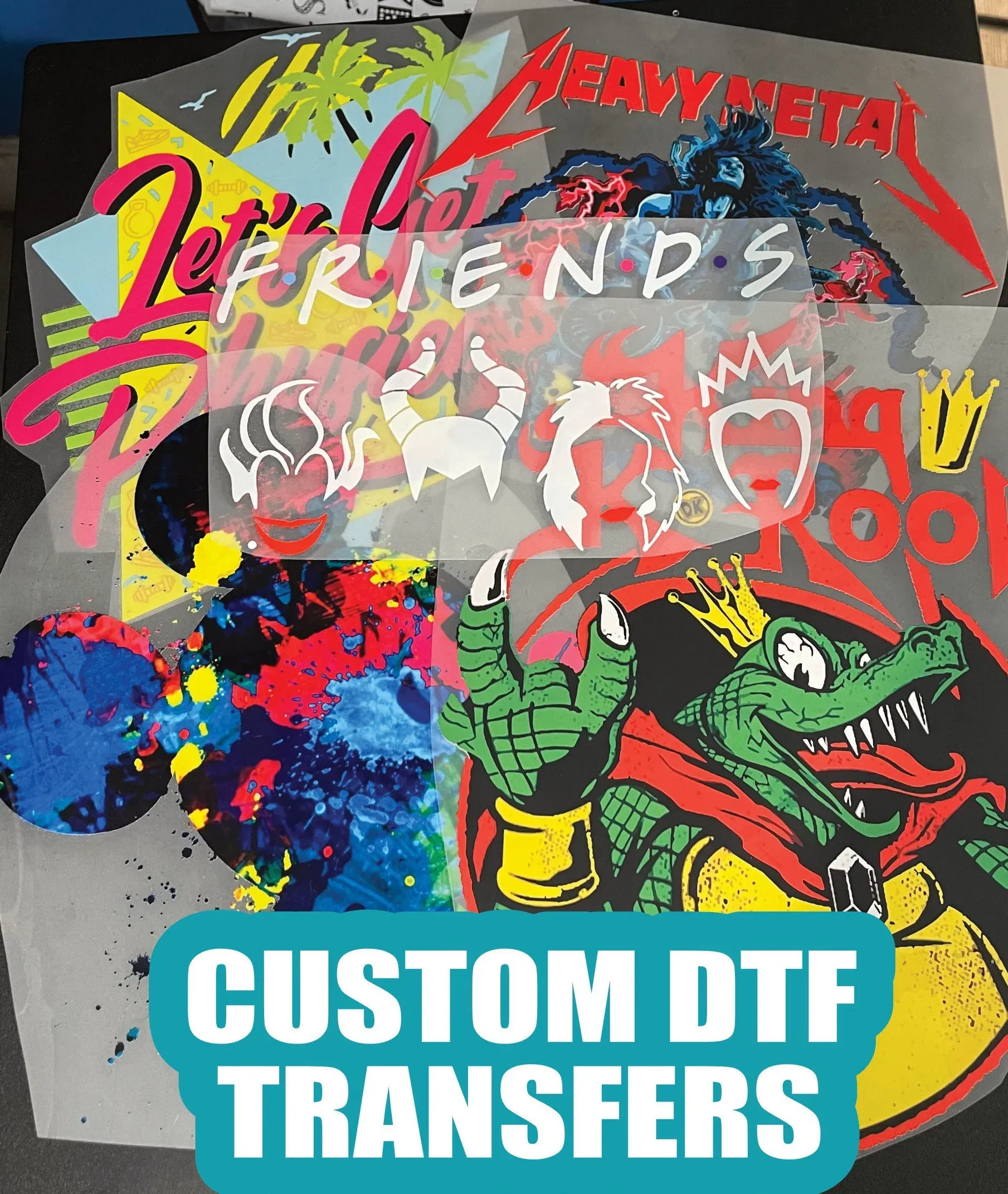

In the competitive landscape of custom printing, **DTF Transfers** (Direct to Film) are emerging as a game-changer. This innovative printing technique has captivated businesses looking for a cost-effective solution that doesn’t compromise on quality. Unlike traditional methods, DTF transfers are known for their vibrant colors and the ability to handle intricate designs with ease. They offer significant advantages such as quicker turnaround times and flexibility in production, making them an attractive option for small to medium-sized enterprises. As the demand for custom apparel continues to rise, understanding the benefits of DTF printing compared to other printing techniques, like screen printing, is essential for organizations aiming to elevate their brand presence.

When exploring the realm of textile customization, one might encounter several printing methods, including DTF Transfers, Digital Transfers, and traditional methods like Screen Printing. Each technique has unique characteristics that cater to diverse business needs and customer demands. DTF printing stands out for its ability to produce high-quality transfers that adhere seamlessly to various fabrics, providing durability and aesthetic appeal. Meanwhile, screen printing remains a strong contender, particularly for larger orders due to its cost efficiency at scale and vibrant color output. By grasping the principles behind each option, businesses can make informed decisions that align with their operational goals and consumer expectations.

The Rise of DTF Transfers in Textile Printing

DTF Transfers have recently emerged as a transformative solution in the textile printing industry, blending quality with efficiency. Unlike traditional methods, DTF allows for vibrant color reproductions on various fabric types, appealing particularly to businesses that require customization without large initial investments. This adaptability makes DTF not only beneficial for small business owners but also for established brands looking to diversify their printing techniques. By leveraging this modern approach, companies can meet increasing consumer demands for personalized apparel swiftly and efficiently.

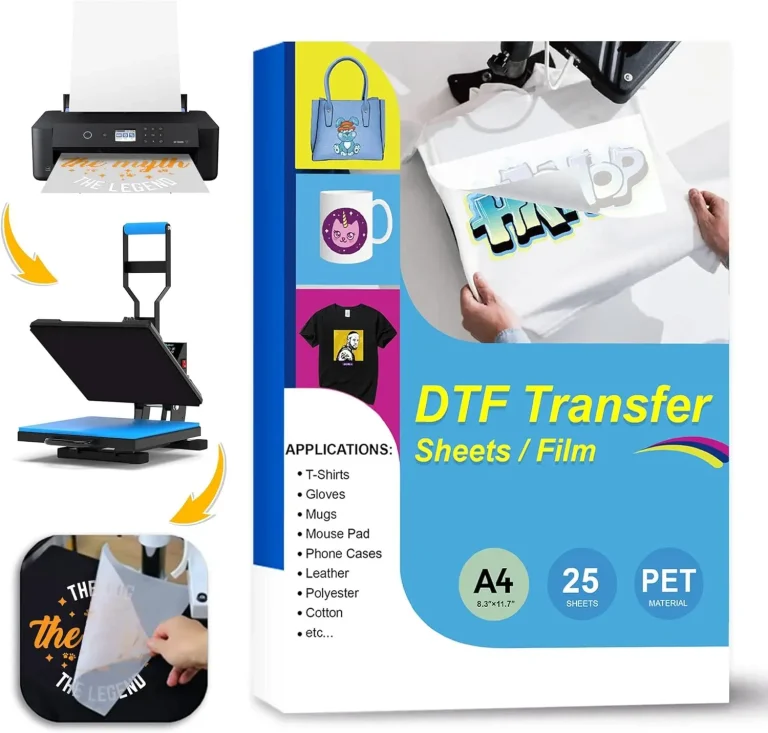

With DTF technology becoming more accessible, several companies are ramping up production capabilities. Innovations such as improved inks and printing machinery are regularly introduced to the market, demonstrating a strong commitment to quality output and sustainability in printing. As businesses navigate their printing needs, understanding the detailed workings of DTF transfers will enable them to make informed decisions that align with their branding strategy.

Cost-Effectiveness: DTF Transfers vs. Screen Printing

When it comes to cost management in printing, DTF Transfers shine brightly, especially for small-scale orders. The initial setup costs are considerably lower than those of screen printing, making it feasible for businesses that cannot afford hefty startup investments. Additionally, since DTF allows for smaller print runs without compromising on quality, companies can offer personalized services while maintaining healthy profit margins. This cost-effectiveness is a significant advantage for startups that rely heavily on custom designs.

On the flip side, screen printing can offer substantial savings when bulk orders are on the table. Its economy of scale comes into play as production quantities increase, dramatically reducing the cost per unit. Though the setup is pricier, when projected over large quantities, screen printing becomes a worthwhile investment, particularly for larger businesses that regularly fulfill big orders.

Durability in Printing: DTF Transfers vs. Screen Printing

Durability serves as a critical factor when assessing printing methods. Screen printing is renowned for its long-lasting results; products printed using this method tend to withstand heavy use and repeated washings, making it the preferred choice for promotional items or workwear. Clients often appreciate this longevity, confident they are getting value for their investment as their screen-printed clothing maintains its vibrant colors over time.

Conversely, while DTF Transfers may not match the durability of traditional screen printing, they offer a unique softness that enhances comfort—a major consideration for apparel. The ability of DTF prints to stretch without cracking and their resistance to fading make them suitable for items that require high-quality aesthetics and performance. Understanding the application and usage of each printing type can guide businesses in selecting the best option for their client base.

Comparing Production Speed: DTF vs. Screen Printing

In today’s fast-paced market, production speed can significantly impact a business’s bottom line. DTF Transfers typically allow for quicker turnaround times, which is crucial for businesses needing to launch trends swiftly or respond to customer orders promptly. The streamlined production process not only enables rapid fulfillment but also minimizes downtime, essential for small businesses operating on tight schedules.

Contrastingly, screen printing involves more extensive preparation, such as creating screens and setting up the printing environment. While one can produce many items simultaneously, the initial bulk setup can lead to delays, especially for smaller runs. Companies should weigh their urgency against production capabilities to determine which printing method aligns with their operational goals.

The Innovations Shaping DTF Printing Technology

As DTF technology evolves, innovation plays a crucial role in expanding its potential. The introduction of advanced printers and specialized inks has made it easier for businesses to achieve high-quality results that rival traditional methods. For instance, companies like LOKLiK are revolutionizing the landscape by making DTF printing equipment more accessible and efficient for small business owners. Innovations like automated print systems facilitate seamless operation, thus encouraging more brands to explore this technique.

Further advancements, such as eco-friendly inks and improved transfer films, are also gaining traction in the DTF printing space. These developments do not only enhance the sustainability aspect of printing but also ensure that businesses can meet the growing demand for ethically produced textiles. Keeping abreast of these innovations equips businesses with the knowledge they need to stay competitive and appealing to eco-conscious consumers.

Final Considerations for Choosing Between DTF Transfers and Screen Printing

When deciding between DTF Transfers and screen printing, businesses must evaluate their specific needs and goals. Factors such as order size, visual preferences, durability requirements, and budget constraints come into play. For businesses focusing on custom and limited edition items, DTF transfers may emerge as the practical choice. On the other hand, those needing consistent quality for large volumes might find screen printing to be the better option.

Ultimately, understanding the strengths and weaknesses of both printing methods allows businesses to optimize their operations and cater to their customer needs effectively. By selecting the right technique, companies can ensure they provide high-quality, appealing products that resonate with their target market, helping them achieve growth in a competitive environment.

Frequently Asked Questions

What are DTF Transfers and how do they compare to screen printing?

DTF Transfers, or Direct to Film transfers, are a modern printing technique where designs are printed onto a film and transferred onto fabric using heat and pressure. In comparison to screen printing, DTF transfers are often more cost-effective for smaller runs, provide quicker turnaround times, and allow for complex designs without the need for color separations.

What are the main advantages of DTF transfers over screen printing?

The primary advantages of DTF transfers include their cost-effectiveness for small orders, faster production speeds, flexibility in intricate designs, and a soft feel on fabric. While screen printing excels in durability for larger batches, DTF printing is increasingly favored for personalized, high-resolution prints in smaller quantities.

Why should I choose DTF transfers for my custom apparel?

Choosing DTF transfers for custom apparel is beneficial due to their economical setup costs, ability to produce vibrant colors with detailed designs, and reduced lead times for production, making them ideal for small businesses wanting to offer customized products without high initial investments.

How does the durability of DTF transfers compare to screen printing?

While DTF transfers offer an attractive soft feel and vibrant visuals, they typically do not match the durability of screen printing, which is known for producing long-lasting prints that withstand multiple washes. It’s essential to consider the intended use when deciding between the two methods.

What printing techniques are most cost-effective for bulk orders: DTF transfers or screen printing?

Screen printing is generally more cost-effective for bulk orders due to lower per-unit costs once initial setup expenses are covered. Conversely, DTF transfers shine in smaller runs, making them ideal for businesses that frequently require customized items.

Can DTF transfers achieve vibrant colors like screen printing?

Yes, DTF transfers can achieve vibrant colors comparable to screen printing. This is a significant advantage, as DTF printing allows for high-resolution images in full color without the limitations of color separations typical in screen printing, making it an excellent choice for designs requiring intricate details.

| Aspect | DTF Transfers | Screen Printing |

|---|---|---|

| Cost-Effectiveness | Lower setup cost; ideal for small runs. | Higher setup cost; more economical for bulk orders. |

| Durability | Less durable; suitable for light use. | Highly durable; withstands multiple washes. |

| Production Speed | Quick production, particularly for smaller quantities. | Slower due to setup and labor requirements. |

| Design Flexibility | Can produce complex, full-color designs easily. | Limited to color separations and fewer design intricacies. |

| Feel on Fabric | Soft feel; less heavy on fabric. | Heavier ink application; textured effects available. |

Summary

DTF Transfers offer a modern and cost-effective solution for businesses looking to customize apparel and textiles. With lower setup costs and the ability to produce complex designs quickly, DTF printing becomes a viable option for small to medium orders. This technology’s advancements make it increasingly attractive for new businesses aiming to provide high-quality, personalized products to their customers. However, screen printing maintains its position in the market for large-scale orders due to its durability and vibrant color outputs. Ultimately, the decision between DTF transfers and screen printing should be guided by your specific business needs, as both methods have unique advantages that can support your goals.