DTF Transfers vs. Other Printing Techniques: Key Insights

DTF Transfers have emerged as a game-changing printing technique in the garment decoration industry. Unlike traditional methods such as screen printing or DTG printing, Direct-to-Film (DTF) printing provides a versatile and efficient way to create vibrant designs on fabric. The process utilizes a special film and heat application to ensure that colors pop and intricate details are preserved, making it a favorite among both manufacturers and small businesses alike. As fashion trends demand high-quality visuals, DTF Transfers deliver the performance and durability required for modern apparel. In comparison to printing techniques like sublimation printing, DTF stands out for its compatibility with a wider range of fabrics, paving the way for endless creative possibilities.

In the evolving landscape of textile printing, the exploration of alternatives to conventional methods unveils exciting prospects. Techniques often referred to as Direct-to-Film Transfers encompass innovative approaches that leverage heat and unique films to transfer designs onto garments. This method, distinct from traditional screen printing or even Direct-to-Garment (DTG) printing, allows for greater efficiency and adaptability, catering to various fabrics. With advancements in printing technology, this technique ensures that businesses can produce high-quality visuals while maintaining cost-effectiveness, particularly for smaller orders. As we delve deeper, it becomes evident that these modern solutions are revolutionizing the way we approach garment embellishment.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing is an innovative method that allows for high-quality prints by transferring designs onto fabric through a specialized transfer film. Unlike traditional methods like screen printing or direct-to-garment (DTG) printing, DTF provides greater flexibility in design. It enables intricate details and vibrant colors, making it suitable for a wide range of applications from t-shirts to tote bags. The ease of use and minimal setup make DTF printing a popular choice among both amateur crafters and professional businesses.

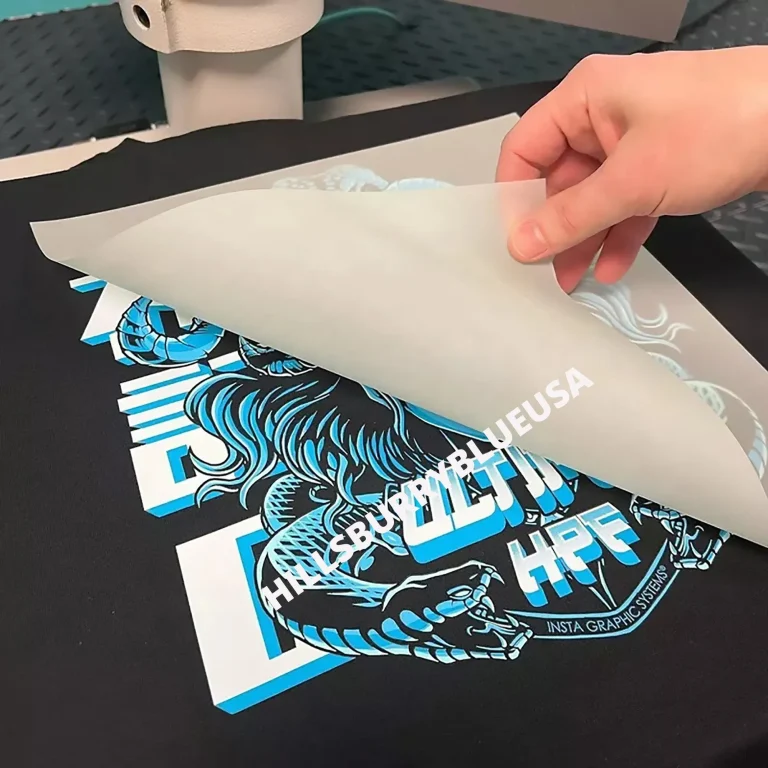

One of the key aspects of DTF printing is its compatibility with various fabric types, including cotton, polyester, and blended materials. This adaptability sets DTF apart from other techniques, particularly DTG, which often struggles with the nuances of printing on darker or synthetic fabrics. Additionally, the DTF process involves a straightforward workflow: printing, powder application, curing, and heat transfer. This simplicity not only streamlines operations but also enhances the overall speed of production, making it an efficient option for garment decorators.

Comparing DTF Transfers with Screen Printing

Screen printing has long been a favorite in the garment industry, known for its ability to produce vibrant and durable designs. However, DTF transfers offer several advantages that are reshaping the landscape of garment decoration. While screen printing is primarily suited for large production runs, DTF printing shines in scenarios where small batches are needed without compromising on quality. This makes it the ideal go-to for businesses looking to offer personalized items for events, promotions, or small collections.

Moreover, the color vibrancy and detail achievable through DTF printing can often surpass that of screen printing, particularly when dealing with detailed graphics or photographs. The ability of DTF transfers to print in full color on a variety of fabric types also adds to its appeal. As consumer demand shifts towards customization and unique designs, DTF printing not only meets these needs but does so with a level of precision that often eludes traditional screen printing methods.

Exploring DTF vs. DTG Printing Techniques…

Frequently Asked Questions

What makes DTF Transfers unique compared to screen printing?

DTF Transfers, or Direct-to-Film printing, stands out from screen printing due to its versatility in printing on various fabric types, including both light and dark materials. Unlike screen printing, which often requires multiple screens for different colors, DTF transfers allow for vibrant, intricate designs printed directly onto a transfer film, making it easier and more cost-effective for both small and large runs.

Can you explain the DTF printing process?

The DTF printing process involves four key steps: first, designs are printed onto a special transfer film using DTF printer technology. Next, a powdered adhesive is applied to the printed design, which is then cured through heat to bond the adhesive. Finally, heat is applied again to transfer the design onto the fabric, resulting in high-quality prints that exhibit excellent durability and detail.

How does DTF Transfers compare to Direct-to-Garment (DTG) printing?

While both DTF Transfers and DTG printing cater to high-quality fabric designs, DTF is more versatile as it works effectively on a wider array of fabrics, including those that are dark or difficult for DTG technology. Additionally, DTF is generally more cost-efficient for short run orders, as it avoids the lengthy setup required in DTG printing.

What are the durability benefits of using DTF Transfers?

DTF Transfers provide exceptional durability as they are resistant to cracking and fading, making them ideal for garments that will undergo frequent washing. The combination of the bonding adhesive and the transfer film ensures that the designs maintain their vibrant colors and integrity over time, outperforming many traditional printing methods.

Is DTF Transfers suitable for small businesses?

Yes, DTF Transfers are extremely suitable for small businesses due to their cost-efficient setup and the ability to produce high-quality prints without the need for large quantities. This technique allows small businesses to easily fulfill custom orders and adapt quickly to market demands without incurring the costs associated with bulk screen printing.

Are DTF Transfers environmentally friendly compared to sublimation printing?

DTF Transfers can be considered more environmentally friendly than sublimation printing when it comes to fabric compatibility. While sublimation requires synthetic fabrics to achieve vibrant prints, DTF works on a variety of materials, including natural fibers. Additionally, DTF’s lower energy consumption during the printing process can make it a more sustainable option in some cases.

| Key Points | Details |

|---|---|

| DTF Transfers Explained | DTF (Direct-to-Film) printing transfers designs from a special film onto fabric using heat, ensuring vibrant and detailed graphics. |

| Steps in the DTF Process | 1. Printing: Uses a DTF printer to print designs on transfer film. 2. Powder Application: A powdered adhesive is applied. 3. Curing: The adhesive is heated to bond with the film. 4. Transfer: Final heat application transfers the design to fabric. |

| Advantages of DTF Printing | 1. Versatile across various fabrics. 2. Cost-effective for small orders compared to other methods like screen printing. 3. Durable against wear, perfect for regular washing in apparel. |

Summary

DTF Transfers are revolutionizing the garment decoration industry with their innovative and efficient approach to printing. Offering stunning visuals, DTF printing is especially advantageous for both large manufacturers and small businesses alike, thanks to its versatility and cost-effectiveness. By utilizing a straightforward process that ensures durability and longevity of prints, DTF Transfers have become a preferred choice in the fashion sector, effectively meeting the demands for high-quality, resilient designs.