DTF transfers vs HTV: Best T-shirt printing method

DTF transfers vs HTV is a hot topic for makers and small businesses seeking reliable, eye-catching T-shirts. Understanding DTF printing vs heat transfer vinyl helps weigh color capabilities, texture, and wash durability, especially when you compare it to screen printing. This guide compares how designs are created, how they feel on fabric, and how they hold up after washing, highlighting the soft hand feel you can expect. We’ll touch on setup costs, production speed, and the kinds of artwork that best suit each method. Whether you’re building a T-shirt line or tackling a DIY project, selecting the right method starts with clear expectations and practical tips.

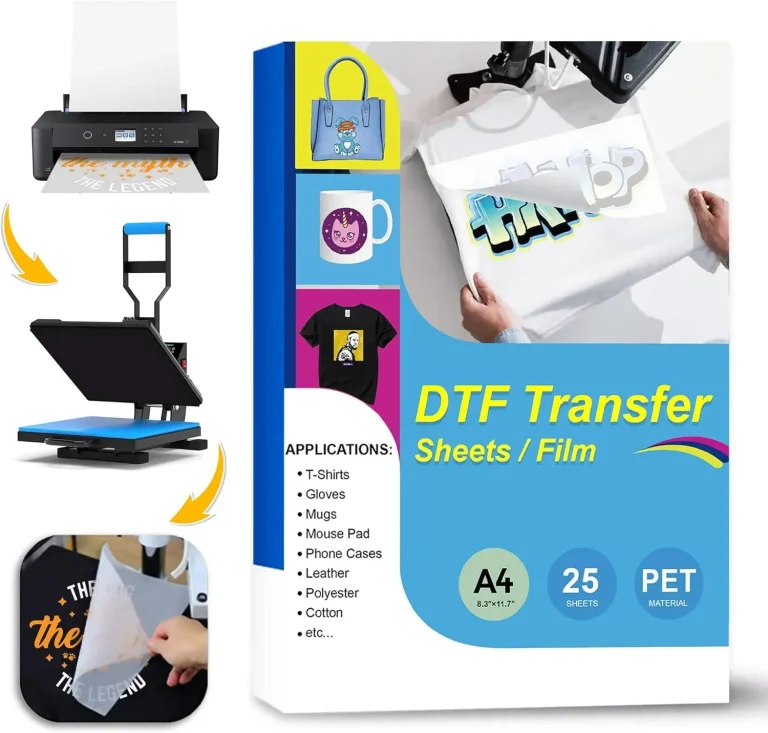

Beyond the brand names, many creators refer to film-based transfers versus cut vinyl as two core approaches to garment graphics. Direct-to-film processes rely on printing full-color artwork on a transparent medium, which is then bonded to fabric with adhesive powders and a top coat. In contrast, the vinyl-on-fabric route uses a cutter, weeding, and heat to fuse pre-cut pieces that form the final image, offering tactile texture and fast results. Consider color richness, texture, and durability when choosing between these paths, as color complexity tends to lean toward film-based methods while simpler logos often favor vinyl. A practical approach for many shops is a hybrid workflow: keep DTF for complex artwork and use printable or standard vinyl for straightforward typography or accents. This strategy blends flexibility with efficiency, helping you meet deadlines and budget constraints.

DTF transfers vs HTV: Key differences in color, texture, and durability

DTF transfers, or direct-to-film, leverage a full-color printing process (DTF printing) that captures gradients and fine details with a vibrant finish. HTV relies on vinyl cutouts that are heat-pressed, which excels for solid blocks of color and typography but can struggle with photographic complexity. The result is that DTF can achieve more nuanced color fidelity, while HTV can be quicker for single-color or few-color designs. This makes DTF printing a strong choice for artwork that benefits from smooth color transitions, while HTV shines when speed and simplicity are paramount.

Texture and hand feel differ between the two methods. DTF transfers tend to feel softer and more flexible because the film and adhesive layer are relatively lightweight, contributing to a soft hand feel on cotton and blends. HTV, on the other hand, can add noticeable texture, especially with dense or multi-layer vinyl builds. Durability and washability also vary: with proper curing and adhesive powder, DTF often delivers solid washfastness on common fabrics, whereas HTV performance hinges on the vinyl formula and precise pressing conditions. These trade-offs influence not just feel but how the design behaves over time.

Choosing between DTF printing and heat transfer vinyl for your designs: a practical decision guide

For color-heavy artwork and multi-color designs with gradients, DTF printing provides rich color fidelity and the ability to reproduce complex art without the need for multiple screens or color-by-color setups typical of traditional screen printing. In contrast, heat transfer vinyl offers speed and cost efficiency for simple logos or typography, especially in small runs. Understanding these differences helps you align the method with your project’s visual complexity and production timeline.

Consider production volume, garment types, and the desired hand feel when deciding between DTF printing and heat transfer vinyl. A hybrid approach can also be effective: use DTF for complex, photographic-style designs and reserve HTV for straightforward text or simple logos to optimize workflow and margins. Don’t forget to factor in durability, wash conditions, and clear care instructions to maintain the quality of either method—and if needed, reference alternatives like screen printing for high-volume, full-color runs where the setup can be amortized over many shirts.

Frequently Asked Questions

DTF transfers vs HTV: How do DTF printing and heat transfer vinyl compare in color fidelity, soft hand feel, and wash durability on garments?

DTF printing offers superior color fidelity and smooth gradients, while heat transfer vinyl (HTV) is best for solid colors. In terms of hand feel, DTF is typically soft when cured properly, though the film layer can add a thin touch; HTV often feels more textured, especially with dense vinyl. Durability and washability are strong for both when correctly applied, with DTF generally showing reliable washfastness on cotton and blends. Setup and cost differ: DTF requires an inkjet printer, transfer film, adhesive powder, and a curing step, whereas HTV relies on a cutter and vinyl stocks. Best use: choose DTF transfers for artwork and photos; choose HTV for simple logos or typography and quick, small-batch runs.

DTF transfers vs HTV for high-volume apparel: how do costs and setup compare, and where does screen printing fit as an alternative—considering soft hand feel on fabric?

For large runs of color-rich artwork, DTF printing can provide strong color fidelity with fewer color-change steps than traditional multiple-color processes, while screen printing remains a staple for very high-volume, simple-color designs. HTV tends to be faster and cheaper per shirt for small, personalized batches with 1–4 colors. Setup and costs: DTF needs an inkjet printer, curing equipment, film, and powders; HTV requires a cutter and a range of vinyl; screen printing needs screens, ink, and setup per color. Hand feel varies: DTF can feel very soft when applied well; HTV may feel thicker or more textured depending on the vinyl used; screen printing outputs can feel heavier due to ink deposit. Use cases: DTF for complex, color-rich artwork across sizes; HTV for quick-turn personalization and simple designs; screen printing for very large volumes of basic colors. A hybrid approach—using DTF for complex elements and HTV for simple logos—can optimize workflow and margins.

| Key Point | DTF transfers | HTV |

|---|---|---|

| How designs are created | DTF: Printed on transfer film with water-based pigment ink, then powder adhesive and a top layer; cured and transferred with a heat press. | HTV: Cut or plot designs from vinyl, weed away negative space, and fuse onto fabric with a heat press. |

| Color capability | Full-color, smooth gradients, and photographic quality. | Solid blocks of color; multi-color designs possible with extra steps; printable vinyl options bridge the gap. |

| Feel/hand on fabric | Soft and flexible; the film layer adds some feel but remains relatively soft. | Texture is more noticeable, depends on vinyl thickness and density. |

| Durability & washability | Excellent washfastness on cotton/blends when applied properly. | Durable but depends on vinyl quality and application conditions. |

| Setup & cost | Printer, curing system, film, and adhesive powder; higher upfront but economical per-shirt for large runs. | Cutter and vinyl; quick for small runs; cost-effective for simple designs; ongoing vinyl inventory costs. |

| Color complexity | DTF naturally handles multi-color/photographic designs well. | HTV can achieve detail with printable vinyl but is more manual for many colors. |

| Best-use scenarios | Full-color artwork, photographs, gradients; scalable across sizes; lightweight hand. | Simple logos/text, personalization, small batches; tactile vinyl finishes. |

| Care and maintenance | Follow garment care; wash inside-out; avoid high heat drying when possible. | Similar care guidelines; avoid high heat; follow vinyl care recommendations. |

| Hybrid approach | Use DTF for complex artwork across sizes to streamline production. | Use HTV for simple logos/typography to speed up small runs; combine with DTF for complex pieces. |

Summary

DTF transfers vs HTV is a topic many small businesses and hobbyists weigh when deciding how to print custom T-shirts. DTF transfers excel at full-color artwork, gradients, and a soft hand, making them ideal for complex designs and photographic imagery across multiple sizes. HTV shines for simple logos, typography, and personalized items with fast setup and favorable per-shirt cost on small runs, especially when a tactile vinyl finish is desired. Your choice should consider design complexity, production volume, garment feel, and budget. A practical approach often blends the two: use DTF for intricate artwork and HTV for straightforward logos or typography to optimize workflow, cost, and margins.