DTF Transfers: Unlocking Quality and Versatility in Printing

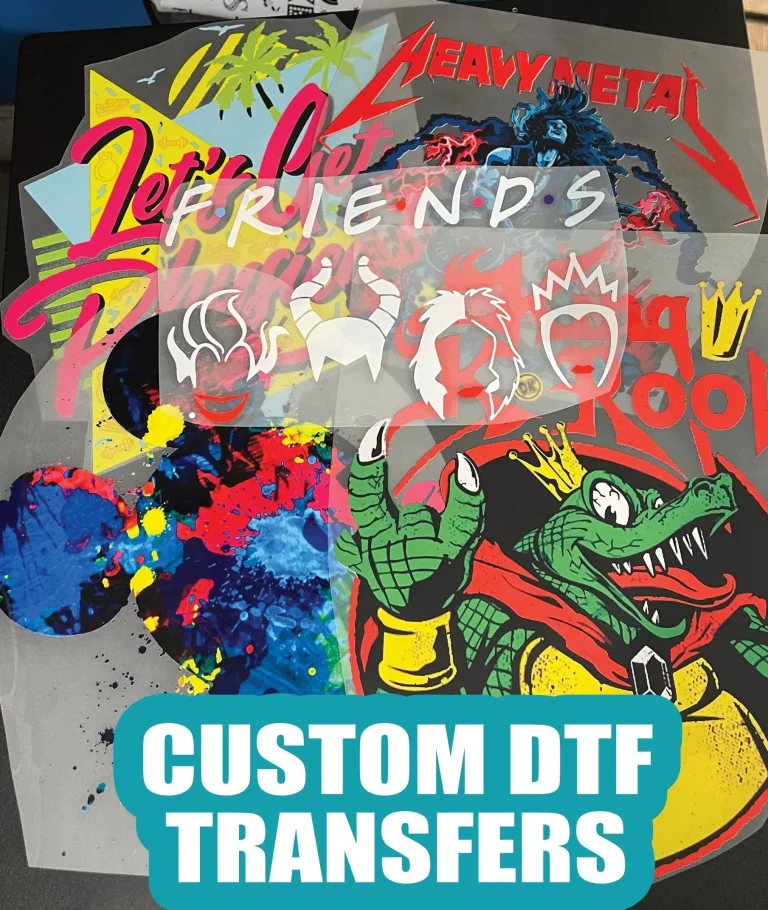

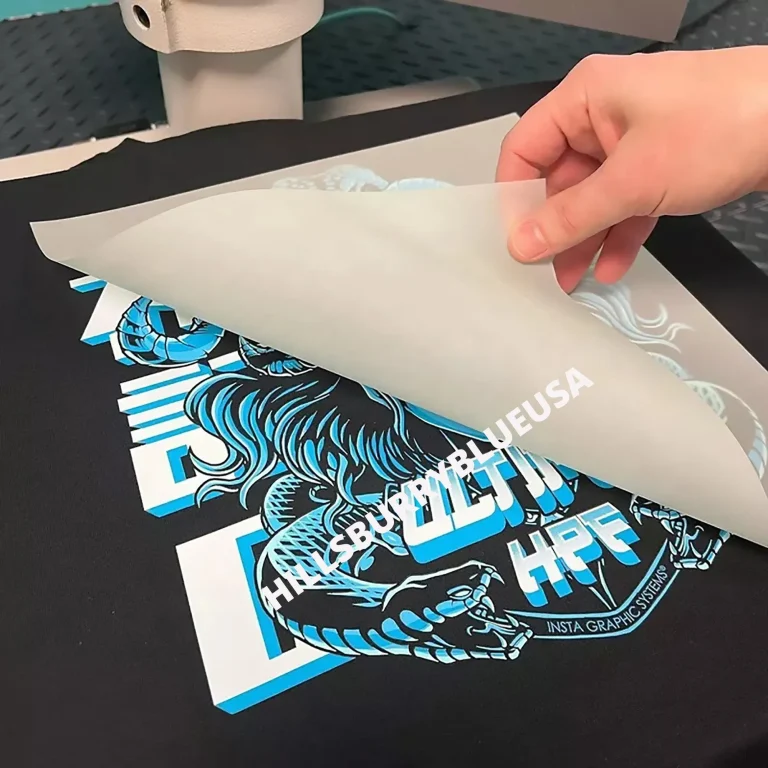

DTF Transfers, or Digital Transfer Film Transfers, have swiftly emerged as a vital innovation in the world of custom printing, enabling creators to produce high-quality designs with remarkable efficiency. This cutting-edge technology allows for seamless printing on a variety of fabrics, ensuring vibrant colors and durability that meet today’s consumer expectations. Whether you’re a small business owner or a passionate hobbyist, DTF transfers provide a compelling solution for vibrant heat press transfers that stand out in the crowded marketplace. With a focus on sustainable printing practices, these transfers utilize water-based inks that are gentle on the environment while delivering exceptional results. In this article, we’ll explore the myriad benefits of DTF transfers and why they are revolutionizing the way custom printing is approached.

Often referred to as digital heat transfer solutions, DTF transfers represent a transformative approach to garment decoration and personalized products. This technique leverages the versatility of innovative printing methods that can be applied to various materials, from textiles to leather. By providing quality printing solutions, this technology allows businesses to streamline their operations and expand their offerings with ease. As interest in eco-friendly practices grows, digital transfer film serves as an ideal alternative for those looking to produce customized items sustainably. In this discussion, we will uncover the reasons behind the increasing popularity of digital heat transfer solutions and their impact on the custom printing industry.

Understanding DTF Transfers and Their Technology

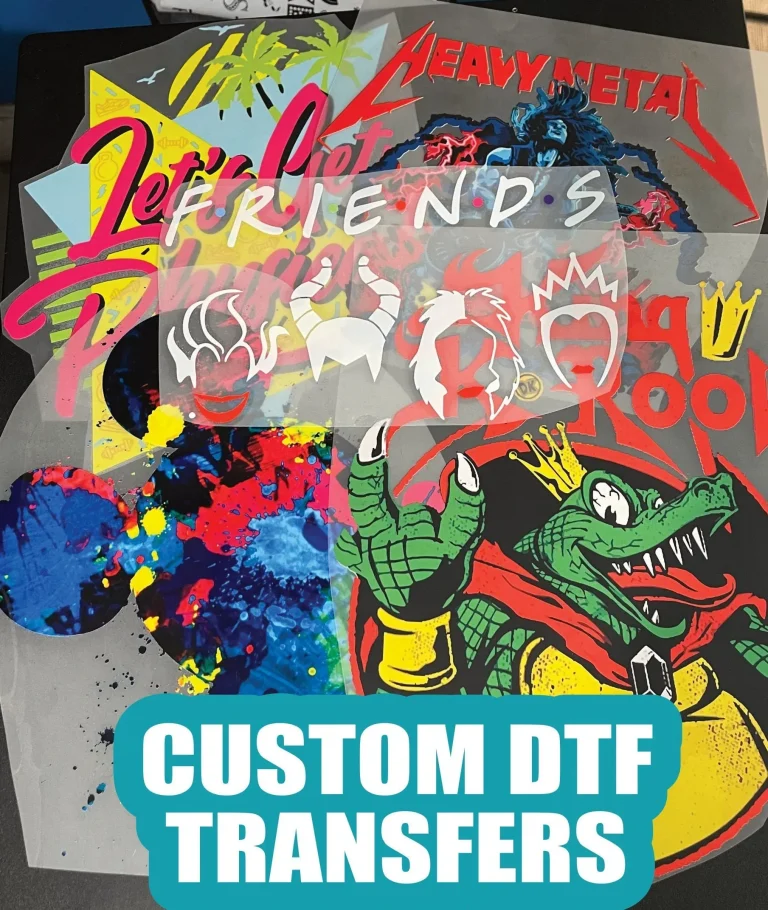

DTF Transfers, or Digital Transfer Film Transfers, represent a significant advancement in custom printing technology. At the heart of this process is the innovative use of water-based inks that allow for vibrant colors and detailed designs to be transferred onto various substrates. Unlike traditional methods, DTF employs a unique combination of transfer film and adhesive, resulting in prints that not only look great but are also incredibly durable. With this technology, businesses can achieve a professional finish that appeals to customers seeking high-quality custom apparel.

The DTF process allows print shops to create intricate designs that capture the nuances of the original artwork. This level of detail is essential for brands looking to establish strong visual identities. Furthermore, DTF transfers can be applied easily through heat pressing, making the production process straightforward even for those new to the custom printing industry. As more creators and businesses discover the efficiency and quality of DTF, it’s clear that this technology is reshaping the landscape of digital printing.

Versatile Applications of DTF Transfers

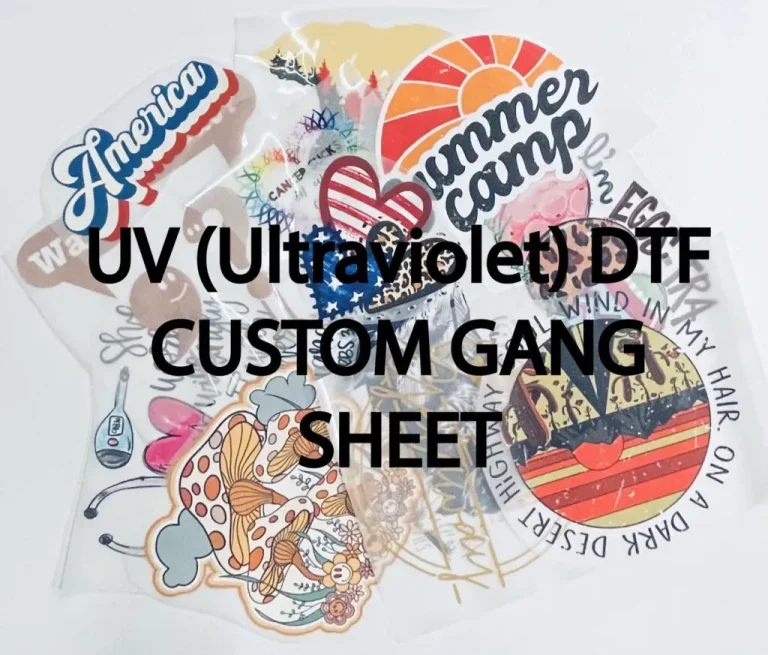

One of the most compelling advantages of DTF transfers is their versatility in application. DTF technology is compatible with a wide array of materials, including cotton, polyester, leather, and even synthetic fabrics. This flexibility means that businesses can diversify their product range, moving beyond just t-shirts to include items like hoodies, bags, and even promotional stickers. The ability to print on various substrates without compromising quality allows custom printing shops to cater to a broader demographic.

Moreover, the versatility of DTF transfers is not only limited to the types of materials but also extends to the types of products that can be created. For instance, companies can create customized apparel for sports teams, branded merchandise for events, and personalized gifts for special occasions. This adaptability can streamline production and open up new revenue streams, allowing businesses to tap into niche markets that require high-quality, custom printing solutions.

Cost-Efficiency of DTF Printing

Cost-effectiveness is a pivotal factor in the decision-making process for businesses entering the custom printing market. DTF printing stands out due to its lower setup and operational costs compared to more traditional printing methods like screen printing. This is particularly advantageous for startups and small businesses, as it allows them to produce high-quality prints without significant upfront investment. The efficiency of DTF transfers also reduces material waste, which can lead to further savings in both time and resources.

Additionally, DTF transfers enable businesses to offer competitive pricing while maintaining a high standard of quality. This means that even small-run projects can be economically viable, a crucial aspect for freelancers and hobbyists looking to break into the market. By utilizing DTF technology, companies not only minimize overhead costs but can also provide customers with affordable, high-quality custom apparel that meets their unique needs.

Sustainability in DTF Printing Technology

Sustainability is becoming increasingly important in today’s printing industry, and DTF transfers are paving the way for more eco-friendly practices. The water-based inks used in DTF printing minimize environmental impact, aligning with the growing consumer demand for sustainable printing solutions. Brands that prioritize eco-friendly production methods can enhance their reputation and attract a customer base that values environmentally responsible practices.

By adopting DTF technology, businesses can demonstrate their commitment to sustainability while also delivering high-quality customized products. Not only does this approach help to protect the environment, but it also positions companies favorably among consumers looking to make conscientious purchasing decisions. Sustainable printing practices not only contribute to a healthier planet but also foster brand loyalty among environmentally conscious buyers.

As the demand for sustainable products continues to grow, integrating eco-friendly practices into the custom printing process can provide a competitive edge. DTF transfers reflect an industry-wide shift towards responsible production, offering businesses a way to remain relevant while serving a conscientious market.

Streamlined Production with DTF Transfers

The ease of use associated with DTF transfers is another significant benefit that sets this technology apart. Traditional printing methods often require multiple steps, specialized equipment, and extensive training. In contrast, DTF printing simplifies the workflow by allowing creators to produce high-quality designs using just a heat press. This reduces technical barriers for newcomers in the custom printing industry, enabling them to quickly learn and operate the equipment with minimal training.

The streamlined production process associated with DTF transfers not only saves time but also allows for faster turnaround on orders. This quick response time is crucial for businesses looking to meet consumer demand and seize market opportunities. By adopting DTF technology, businesses can efficiently manage small and large orders alike, making it an invaluable asset in today’s fast-paced printing landscape.

The Rising Popularity of DTF Transfers

As we advance through 2023, the popularity of DTF transfers continues to rise among businesses looking to elevate their custom printing capabilities. This technology’s capacity to deliver high-quality results with remarkable efficiency has caught the attention of many in the industry. Reports indicate that a growing number of companies are embracing DTF printing for their garment decoration and promotional products, as the benefits become more widely recognized.

In an environment where competition is fierce, leveraging DTF technology can provide a crucial edge. Businesses that utilize DTF transfers can offer stunning, durable customized products more efficiently, making them more appealing to potential customers. As awareness regarding the advantages of DTF printing grows, those who integrate this innovative technology will likely find themselves leading the pack in meeting evolving consumer demands and enhancing their product offerings.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Digital Transfer Film Transfers, utilize a unique printing process where high-quality, water-based inks are printed onto a special film. This film is then used to transfer vibrant designs onto various materials using a heat press. The method simplifies application and produces durable, high-quality prints that are suitable for a range of fabrics.

Are DTF Transfers cost-effective for small businesses?

Yes, DTF Transfers are highly cost-effective, especially for small businesses. The lower setup costs and efficient application process help reduce overall expenses compared to traditional screen printing. Additionally, the minimized material waste associated with DTF printing allows businesses to maintain quality while saving on resources.

What types of materials can DTF Transfers be applied to?

DTF Transfers are versatile and can be used on a wide array of substrates, including cotton, polyester, leather, and certain plastics. This flexibility allows custom printing businesses to cater to diverse markets, expanding their product offerings beyond just apparel to include promotional items and accessories.

How do DTF Transfers compare to traditional printing methods in terms of quality?

DTF Transfers are known for their high-quality output, producing vibrant colors and intricate designs with exceptional clarity. Unlike some traditional methods that can result in fading or cracking, DTF prints are designed to withstand multiple washes without losing their quality, making them ideal for custom apparel.

What are the environmental benefits of using DTF Transfers?

DTF Transfers are generally more eco-friendly due to the use of water-based inks that minimize environmental impacts. By choosing DTF printing technology, businesses can align themselves with sustainable practices and attract environmentally conscious consumers who value eco-friendly products.

Why are DTF Transfers becoming increasingly popular in the custom printing industry?

The popularity of DTF Transfers is rising due to their ability to produce high-quality, durable prints efficiently. As businesses seek innovative solutions to meet customer demands for personalized products, DTF technology offers the versatility and quality needed to stand out in a competitive marketplace.

| Key Point | Details |

|---|---|

| High-Quality Output | Produces vibrant colors and intricate designs that are durable and wash-resistant. |

| Versatility of Application | Can be applied to various substrates including textiles, leather, and plastics. |

| Enhanced Ease of Use | Requires only a heat press for application, simplifying the process for users. |

| Cost-Effectiveness | More economical than traditional printing methods, minimizing waste and overhead. |

| Environmental Considerations | Utilizes eco-friendly, water-based inks, appealing to sustainability-conscious consumers. |

| The Growing Popularity of DTF Transfers | Increasing adoption by businesses in the custom printing industry due to its advantages. |

Summary

DTF Transfers are transforming the custom printing industry with their remarkable quality, versatility, and ease of use. As demand for personalized products rises, businesses are increasingly turning to DTF technology to deliver high-quality prints that meet consumer expectations. This innovative method not only provides stunning visual results on a variety of materials but also supports eco-friendly practices with water-based inks. By integrating DTF Transfers into their production processes, companies can respond to market trends efficiently and position themselves ahead of their competitors while catering to the growing consumer preference for sustainable options.