DTF Transfers: Understanding Their Science and Effectiveness

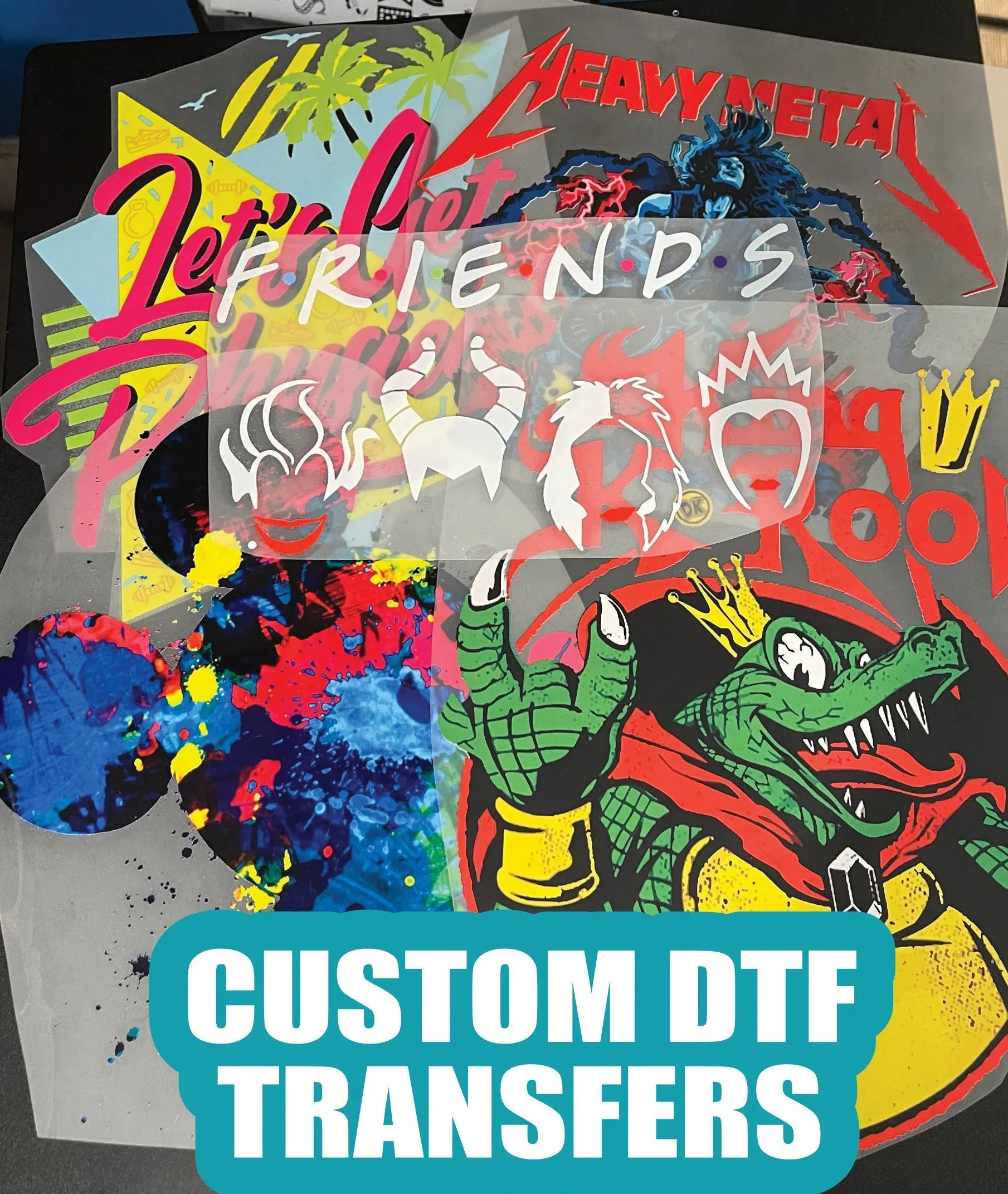

In recent years, DTF transfers, or Direct-to-Film transfers, have emerged as a revolutionary technique in the textile printing industry. By utilizing advanced technology, DTF printing allows for high-quality designs to be transferred onto various fabrics quickly and efficiently. This method not only offers a vibrant array of colors but also provides excellent durability, making it perfect for custom apparel. With an understanding of how DTF transfers work, users can fully appreciate the benefits of DTF printing, from its cost-effectiveness to its versatility in fabric choices. Whether you’re a professional printer or a DIY enthusiast, this DTF printing guide will walk you through everything you need to know to create stunning designs.

Direct-to-Film transfers, often referred to as DTF printing, represent a modern approach to printing designs onto textiles. This method leverages specialized films and inks to achieve results that rival traditional techniques. Many people are discovering the advantages of printing with DTF technology, especially when comparing DTF to DTG printing, where each method serves unique printing purposes. With the growing interest in custom apparel DTF, it’s vital to explore the various applications and best practices associated with this innovative printing solution. Not only does DTF enhance the scope of creative possibilities, but it also simplifies the intricate processes previously associated with other printing techniques.

How DTF Transfers Work: A Detailed Overview

DTF transfers function through a unique process that begins with the creation of the design, which is printed directly onto a specialized PET film using high-quality CMYK DTF inks. This step is crucial, as these inks are designed to maintain vibrant colors and detail throughout the transfer process. Once the design is printed, an adhesive powder is applied to the wet ink, enabling a strong bond when subjected to heat. This innovative method sets DTF apart from traditional printing techniques, as it can adapt to various fabric types without compromising quality.

Following the initial printing, the film undergoes a curing process involving heat, which solidifies the adhesive. This ensures that when heat and pressure are applied via a heat press, the design transfers seamlessly onto the garment. The versatility of DTF transfers is evident, as they can be successfully used on diverse materials such as cotton, polyester, and blends, catering to a broad range of printing needs. This ability to print on both light and dark fabrics enhances its appeal in the custom apparel market.

The Benefits of DTF Printing: Why Choose This Technique?

One of the main benefits of DTF printing is its versatility in application. Unlike many other printing formats, DTF can easily adapt to various fabrics, including those that most techniques, like Direct-to-Garment (DTG), cannot handle. This flexibility makes DTF transfers an ideal choice for custom apparel, enabling designers to work with a wider array of textiles and colors, enhancing their creative options while also meeting client demands.

Moreover, the durability and quality achieved through DTF printing are significant advantages as well. The combination of quality inks and advanced transfer methods results in long-lasting designs that resist fading and peeling, even after multiple washes. This reliability ensures that apparel produced via DTF printing maintains its aesthetic value over time, making it a preferred option for both consumers and businesses looking for cost-effective, high-quality apparel solutions.

Comparing DTF to DTG Printing: Diverging Paths in Customization

When discussing custom apparel, it’s essential to differentiate between DTF and DTG printing technologies. DTF offers a higher level of versatility compared to Direct-to-Garment printing, as it can effectively print on multiple fabrics, including both cotton and polyester blends. While DTG is primarily limited to cotton and requires pretreatment for successful printing, DTF transfers streamline the process by eliminating this extra step, greatly simplifying production and reducing costs for businesses. This comparison highlights how functionality can dictate a business’s choice of printing method.

In addition to fabric versatility, DTF printing can handle larger and more complex designs without the constraints that DTG might impose. This capability allows businesses and designers to produce intricate artwork with ease, promoting a broad range of creative possibilities. For those looking to establish their brand through unique designs on varied substrates, DTF provides significant advantages over DTG, particularly for those working with diverse product lines.

DTF vs Screen Printing: Understanding the Differences

Comparing DTF to screen printing reveals notable differences in application and efficiency. While screen printing is renowned for vibrant colors and durability, it becomes less practical for small or custom orders due to the setup costs involved for each new design. DTF printing, conversely, excels in customization, accommodating multi-color prints without needing a large setup or additional screens for different hues. This flexibility makes DTF an attractive solution for smaller runs and diverse product offerings, as it allows printers to respond quickly to changing demands.

Additionally, DTF transfers support a variety of design complexities, which can be limited in traditional screen printing. The intricate detailing possible with DTF technology means that artists and designers can explore more advanced creative avenues. As businesses grow and customer tastes diversify, the need for adaptable printing methods will increase, positioning DTF as a leading choice in custom printing applications.

Custom Apparel and DTF Transfers: The Perfect Match

Custom apparel is where DTF transfers shine, providing an ideal solution for producing high-quality, personalized items. Businesses can easily create unique designs for events, merchandise, or personal use, capitalizing on the flexibility offered by DTF printing. From sports teams to corporate branding, the potential applications are vast, allowing designers to print anything from intricate logos to colorful graphics with precision and vibrancy.

Moreover, the durability associated with DTF transfers ensures that the designs maintain their integrity even with frequent wear and washing. This longevity adds value for consumers, making DTF a wise investment for companies looking to produce apparel that stands out while withstanding the test of time. As the demand for custom-designed clothing continues to rise, DTF technology is increasingly becoming a favored method within the industry.

Exploring the Applications of DTF Printing Beyond Apparel

While custom apparel is a primary focus of DTF printing, its versatility extends far beyond clothing. Promotional goods, such as tote bags, caps, and other merchandise, can also benefit significantly from DTF technology. The ability to create vibrant, high-quality prints makes DTF a powerful tool for branding efforts and giveaways, allowing companies to effectively promote their messages on various products.

Additionally, artists and crafters can utilize DTF transfers for creative art projects, providing a platform for expressing individuality through fabric. With the capacity to print customized designs, this technology opens doors for innovative creations, making it an excellent option for hobbyists and professionals alike looking to enhance their craft projects with unique, personalized imagery.

Frequently Asked Questions

How do DTF transfers work?

DTF transfers operate by printing designs onto a special polyethylene terephthalate (PET) film using vibrant CMYK inks. After applying an adhesive powder, heat is used to cure the ink, creating a solid bond for transferring the design onto fabrics. This method offers versatile applications, allowing for prints on various materials beyond cotton, such as polyester and blends.

What are the benefits of DTF printing over other methods?

DTF printing offers several key benefits, including versatility across different fabric types, durability of designs that withstand washing, precision in detail for intricate designs, and cost-effectiveness for small orders compared to traditional methods like DTG and screen printing.

Can DTF transfers be used for custom apparel?

Absolutely, DTF transfers are popular in the custom apparel industry, allowing creators to produce personalized items for events, merchandising, or individual wear. The technology enables vibrant prints on a variety of fabrics, making it ideal for diverse custom apparel projects.

What distinguishes DTF printing from DTG printing?

The main difference between DTF and DTG printing lies in the materials they can print on. DTF transfers can print on a wider range of fabrics, including synthetic options, whereas DTG printing is primarily effective on cotton fabrics. Additionally, DTF does not require pretreatment, simplifying the printing process.

Is DTF printing suitable for promotional goods?

Yes, DTF printing is highly suitable for promotional goods. Businesses often utilize this method to create custom-branded items such as tote bags and caps, thanks to its ability to produce high-quality, colorful designs that enhance branding and appeal in giveaways.

How does DTF printing compare to screen printing?

DTF printing offers advantages over screen printing, particularly for small orders, as it does not require extensive setup and allows for full-color designs without needing multiple screens. While screen printing excels in vibrancy, DTF enables flexibility and customization for a broader range of complex designs.

| Key Points | Details |

|---|---|

| Definition of DTF Transfers | A printing method that uses a specialized film to transfer designs onto various fabrics. |

| Versatility | Can print on a wide range of fabric types including cotton and polyester, suitable for both light and dark materials. |

| Durability | Produces designs that resist fading and peeling, making it ideal for frequently washed items. |

| Detail and Precision | Allows intricate design prints with high precision. |

| Cost-Effectiveness | Requires less expensive materials than traditional printing methods, beneficial for small print runs. |

| Comparison with DTG | DTG is best suited for cotton fabrics and requires pretreatment, while DTF supports diverse fabrics. |

| Comparison with Screen Printing | DTF allows for extensive colors and designs without needing multiple screens, making it economical for small batches. |

| Comparison with HTV | HTV is best for simple shapes, while DTF can print complex designs without cutting. |

| Applications in Custom Apparel | Widely used for creating custom designs for events, merchandising, and personal use. |

| Applications in Promotional Goods | Popular for creating branded items like tote bags and caps. |

| Applications in Creative Projects | Empowers artists to produce unique fabric-based designs. |

Summary

DTF transfers are a revolutionary development in the textile printing industry, combining advanced technology with the flexibility to print on various fabric types. This method facilitates the application of vibrant designs while ensuring durability and precision. The versatility of DTF transfers not only makes them suitable for custom apparel production but also for promotional goods and creative projects. With its cost-effectiveness and ability to produce intricate designs, DTF printing is becoming the go-to choice for businesses and DIY enthusiasts alike, positioning it as a frontrunner in the printing sector.