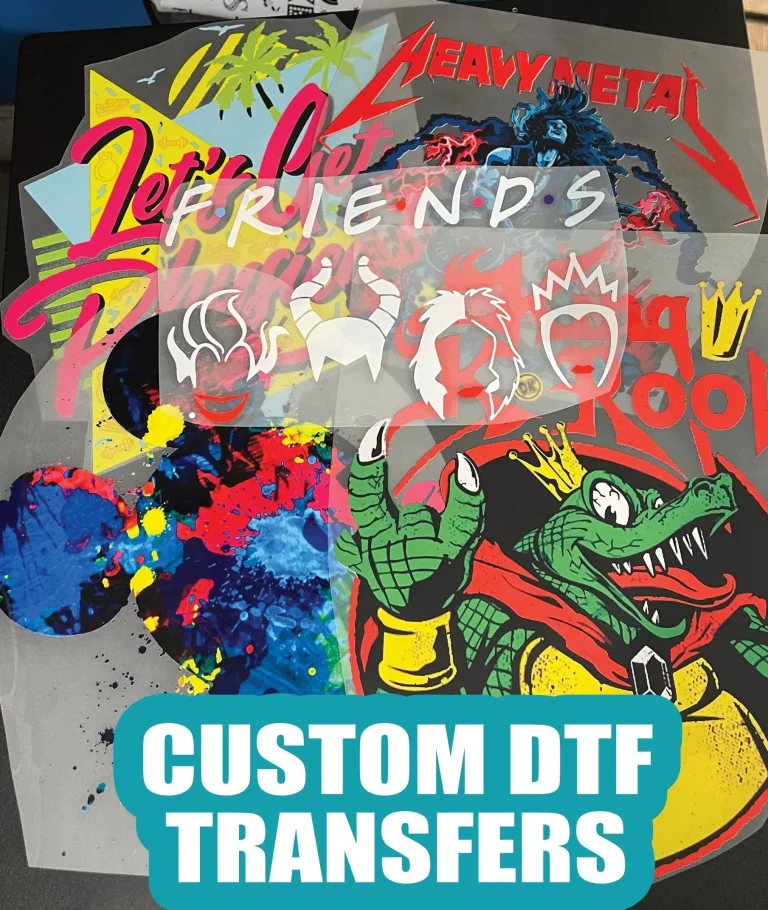

DTF transfers Transforming Custom Apparel in 2025 Today

DTF transfers are redefining how brands approach apparel customization, delivering bold visuals with durable results that stand up to frequent wear and washing. For teams pursuing custom apparel printing, this film based transfer approach offers high color fidelity, reliable edge detail, and a simpler setup compared with many traditional methods. The process works across a broad fabric spectrum, from cotton and blends to certain synthetics, enabling faster design iteration and more consistent results across orders without the need for costly setup changes. Shoppers notice a soft hand and robust wash performance, which helps margins when introducing on demand drops and limited editions. As market demand shifts toward flexible on demand production, these film based transfers are increasingly on the radar for shops seeking scalable color reproduction and faster turnaround.

From an alternative perspective, you can describe the approach as ink-on-film decoration, where a full color design is printed on a transfer film and then heat pressed onto fabric. Other phrases that express the same idea include film based transfers, heat transfer color methods, and on demand garment decoration, all pointing to the same core technology. LSI principles suggest weaving related terms such as color management, substrate compatibility, bonding agents, curing, and workflow optimization to create content that resonates with both people and search engines. Viewed this way, the technique remains a flexible option for short runs, customized drops, and broad fabric compatibility. By framing the topic with diverse language, you signal relevance to broader queries while keeping the focus on reliable, durable, and vibrant results.

DTF Transfers in 2025: Redefining Custom Apparel Printing and the DTF vs Screen Printing Debate

DTF transfers have emerged as a cornerstone for custom apparel printing, delivering vibrant color reproduction, flexible substrate options, and quick turnarounds. In 2025, brands and print shops are choosing direct-to-film transfers over traditional methods to expand their catalog—with durable garment prints that stay sharp through wash cycles and across multiple fabric types. This shift is reshaping workflows, cost considerations, and customer expectations, making DTF printing a strategic asset for on-demand and small-batch production.

Understanding how DTF transfers work—printing a full-color image onto film, applying a bonding agent, and transferring with heat—helps you evaluate the technology alongside DTG and screen printing. When comparing DTF vs screen printing, the film-based approach often offers quicker setup for multi-color designs and greater consistency on dark fabrics, while maintaining a cost structure that scales from small runs to mid-volume productions. For brands aiming for durable garment prints with rich gradients, DTF transfers provide a compelling balance of quality and flexibility.

Optimizing Quality with DTF Printing: Substrates, Curing, and Best Practices for Durable Garment Prints

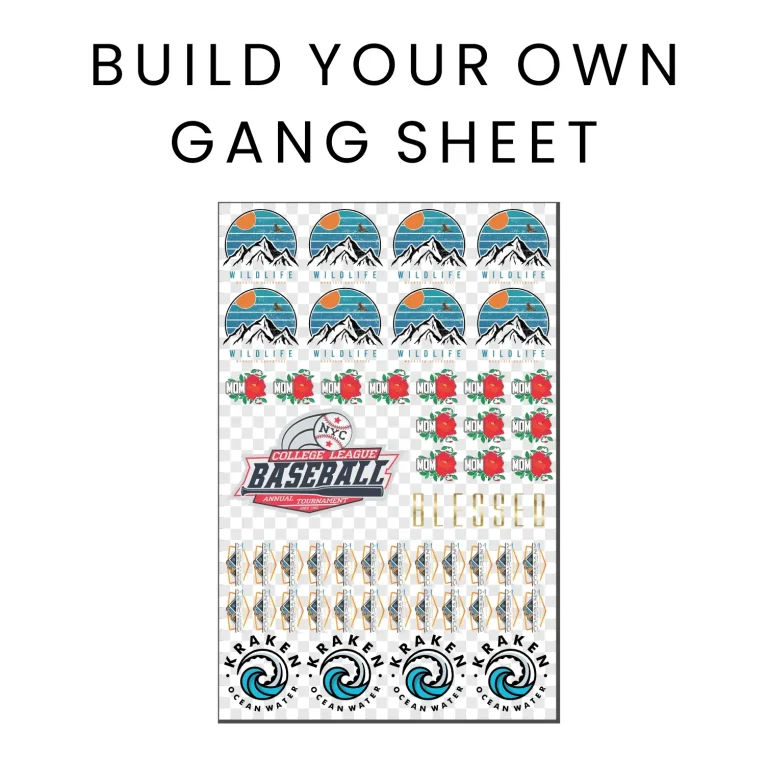

To maximize outcomes in custom apparel printing with DTF transfers, focus on substrate compatibility, adhesive selection, and precise curing. The technology supports cotton, blends, and some synthetics, enabling a broader product strategy without changing machinery. By aligning your DTF printing workflow with reliable curing options and film/powder supplies, you can consistently achieve durable garment prints that retain color fidelity after many wash cycles.

Practical tips include color-managed files, white underlays on dark fabrics to boost brightness, and careful testing before full production. Regular maintenance—calibrating heat presses, cleaning curing beds, and stocking spare films—helps maintain consistency across shifts. When used thoughtfully, DTF transfers can deliver a soft hand with durability, supporting an expanded catalog of custom apparel printing offerings.

Frequently Asked Questions

What are DTF transfers and how do they work for custom apparel printing?

DTF transfers, or direct-to-film transfers, start by printing a full-color design onto a specialized film using DTF printing. After applying a bonding agent, the image is heat-transferred to fabric, delivering a durable, high-resolution print. The process works well across fabrics and often yields a softer hand than vinyl-based methods, while maintaining strong color coverage on dark and light fabrics. DTF transfers enable quick turnaround and are well-suited to custom apparel printing, especially for small runs and on-demand orders. In 2025, improvements in films, powders, and curing options have boosted wash-fastness and color fidelity when properly cured.

DTF transfers vs screen printing: which method delivers durable garment prints for small to mid-volume runs?

DTF transfers, also described as direct-to-film transfers, generally outperform screen printing for small- to mid-volume runs and complex color designs due to easier setup, faster turnarounds, and strong color coverage on many fabrics. The resulting durable garment prints are reliable across cotton, blends, and some synthetics when properly cured and cared for. Screen printing remains cost-effective for very large volumes with simpler color palettes, but its setup, screens, and longer lead times can hinder customization speed. For custom apparel printing strategies in 2025, DTF transfers offer a scalable path for on-demand offerings, rapid quotes, and varied product lines, while maintaining consistent durability and appearance.

| Section | Key Points |

|---|---|

| What are DTF transfers and how they work? |

|

| Why 2025 is a pivotal moment |

|

| Benefits driving adoption |

|

| DTF vs other methods |

|

| Practical implications for your shop |

|

| Design and production tips for best results |

|

| Real-world impact: case studies and examples |

|

| Common myths and how to separate fact from fiction |

|

| The road ahead: trends shaping DTF in the next few years |

|

Summary

DTF transfers are reshaping the custom apparel landscape in 2025 by delivering vibrant color reproduction, fabric versatility, and practical production advantages. For brands and printers, the technology enables on-demand offerings, quicker time-to-market, and durable, high-quality prints across a wide range of fabrics. By embracing direct-to-film transfers and understanding how film, adhesive, curing, and fabric compatibility interact, you can craft a resilient production strategy that meets evolving customer expectations while reducing waste and inventory risk. As the industry evolves, DTF transfers stand as a flexible tool to expand product lines, offer customization, and sustain growth in a competitive market.