DTF Transfers: The Future of Textile Printing Explained

DTF transfers, or Direct to Film transfers, are revolutionizing the landscape of textile printing technology. This innovative printing method enables intricate designs to be printed onto a special film, which can then be seamlessly transferred onto different fabric substrates. As businesses and creators seek to produce vibrant, durable prints, the advantages of DTF printing come to the forefront, showcasing its potential for custom applications across a range of materials like cotton and polyester. With the impressive capabilities of DTF transfers in terms of quality and efficiency, we are witnessing a shift that positions this technology at the precipice of the future of textile printing. Companies like EazyDTF and Mimaki are leading the charge in enhancing this printing solution, highlighting the remarkable growth in the market.

Direct to Film printing, often referred to as DTF transfers, represents an innovative leap in the world of printed fabric applications. This advanced method allows for seamless integration of artistic designs onto textiles, resulting in exceptional detail and vibrant colors. As we explore the landscape of contemporary textile decoration, it becomes evident that the benefits of using custom DTF transfers go beyond traditional constraints, offering enhanced versatility and durability. The increasing popularity of this innovative printing technology reflects the broader trends driving the evolution of fabric customization, which is essential for businesses looking to stay competitive. From the latest releases in printing technology to the rising demand for personalized designs, the future of textile printing is indeed leaning towards DTF solutions.

Understanding the Technology Behind DTF Transfers

Direct to Film (DTF) transfers have revolutionized the way designs are transferred onto fabric. This innovative process involves printing high-quality graphics onto specialized film using advanced printing methods. The films are coated with a transfer adhesive that is activated by heat. Once the film is printed, the design can be applied to various textiles, including cotton and polyester. This method ensures vibrant colors and intricate details that are typically challenging to achieve with traditional printing techniques.

The core advantage of DTF technology lies in its versatility. Unlike some methods that are limited to certain fabric types, DTF transfers can effectively adhere to a wide range of materials, making them suitable for diverse applications such as apparel, bags, and promotional items. This adaptability not only benefits larger businesses but also empowers small-scale creators and custom shops to produce high-quality garments that cater to niche markets.

Exploring the Advantages of DTF Printing

DTF printing offers several key advantages, one of the most notable being its cost-effectiveness. With fewer setup costs compared to traditional screen printing, it allows for production runs of any size, which is particularly advantageous for small businesses and independent designers looking to minimize their financial risk. Additionally, the process generates less waste, contributing to a more environmentally sustainable solution for printing.

Quality is another pivotal advantage of DTF transfers. The technology produces prints that are not only vibrant and detailed but also extremely durable, resisting fading and cracking even after multiple washes. This longevity is a significant selling point in a competitive market where consumers increasingly seek high-quality, long-lasting products. Businesses can assure their clients of superior quality, thus fostering customer loyalty and repeat sales.

Recent Innovations Shaping the DTF Landscape

The recent launch of Snuggle DTF is a landmark event in the evolution of DTF technology. By creating a user-friendly web-to-print platform, Snuggle DTF is making it easier than ever for businesses and resellers to capitalize on the advantages of DTF transfers. This platform simplifies the customization process, enabling users to create unique garments with minimal effort, thus lowering the entry barrier for aspiring entrepreneurs.

EazyDTF’s expansion into large-format printing capabilities further underscores the commitment to advancing DTF technology. By investing in additional printers, EazyDTF is positioning itself as a leader in quick turnarounds and high-volume orders, which is essential for meeting the fast-paced demands of the modern apparel industry. This infrastructural growth not only enhances their operational capacity but also reaffirms the industry’s confidence in the future of DTF printing.

The Customization Revolution with DTF Transfers

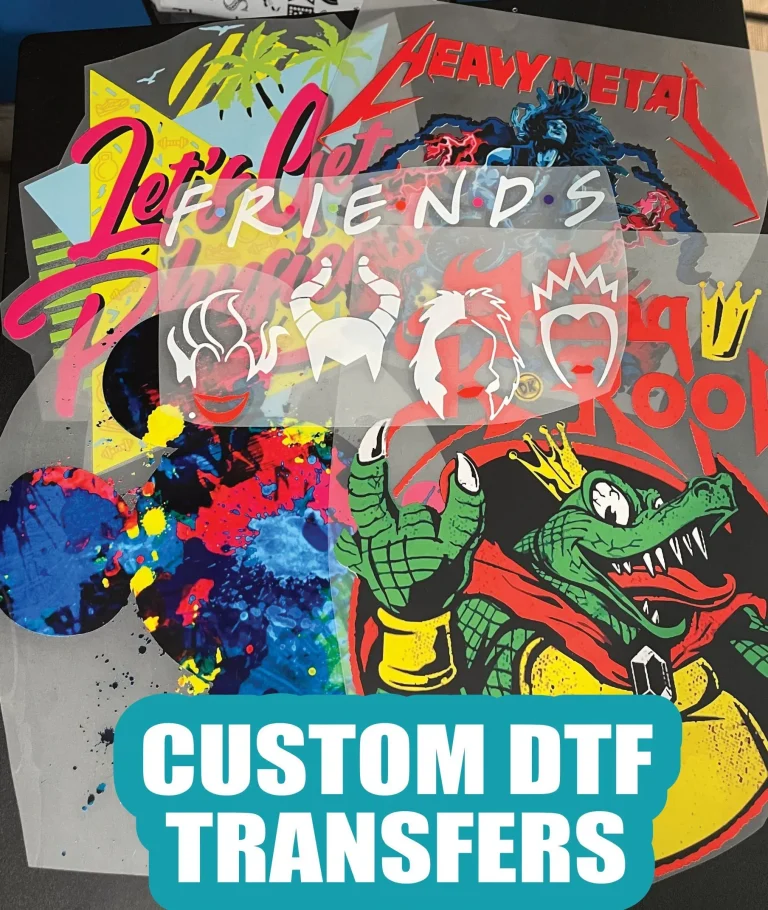

One of the most exciting aspects of DTF transfers is the rise of custom DTF printing services. As consumers shift towards personalized and unique apparel, businesses that harness DTF technology can offer highly customizable options — from custom graphic tees to one-of-a-kind accessory designs. The ease of use and quality output make DTF an attractive solution for on-demand printing, fulfilling the growing appetite for individualized products.

The ability to produce short runs of highly detailed designs without the significant costs associated with traditional methods provides a competitive edge. This opportunity not only caters to the consumer demand for personal expression but also allows small businesses to thrive by providing unique offerings that attract a dedicated customer base. As customization continues to trend, DTF transfers will likely play a pivotal role in shaping the future of textile printing.

Emerging Trends in Textile Printing Technology

The textile printing industry is experiencing rapid advancements, with DTF technology at the forefront of this transformation. Innovations such as Mimaki’s UV DTF technology highlight the potential for printers to produce more than just fabric prints; they can also create high-quality stickers and promotional material. This versatility signifies a shift in how DTF can be utilized, expanding beyond traditional garment printing to various applications.

As these technologies evolve, they are set to revolutionize production methods in the textile sector. The implications of these advancements may lead to more sustainable practices, as efficient production processes minimize waste while enhancing quality. The future of textile printing appears bright, with DTF technology paving the way for new possibilities in customization, efficiency, and quality.

Forecasting the Future of DTF and Textile Printing

The future of DTF transfers seems promising as advancements in technology continue to reshape the textile printing landscape. Companies investing in this technology are likely to gain a competitive advantage by offering innovative, high-quality products that appeal to consumers’ desires for customization and quality. As the industry evolves, we can expect to see DTF technology becoming a preferred choice for both large manufacturers and small print shops.

As the trends suggest, the increasing demand for DTF transfers will not only drive improvements in quality and efficiency but also inspire new patterns of collaboration among businesses. As more enterprises adopt this technology, we will likely witness a transformation in how apparel is designed, produced, and marketed, setting the stage for an exciting new era in textile printing.

Frequently Asked Questions

What are DTF Transfers and how do they work in textile printing?

DTF Transfers, or Direct to Film transfers, are a textile printing technology that allows designs to be printed on a specialized film, which can then be transferred onto various fabrics using heat and pressure. This efficient process delivers vibrant colors and exceptional details, making DTF ideal for T-shirts, hoodies, and more.

What are the key advantages of using DTF printing technology?

The advantages of DTF printing include versatility across different fabric materials, quick production times, cost-effectiveness ideal for custom garments, and high-quality durability with vibrant colors that resist fading. These benefits make DTF transfers a popular choice for both businesses and individual creators.

How does DTF printing compare to traditional textile printing methods?

Compared to traditional textile printing methods, DTF printing offers enhanced versatility and the ability to produce intricate designs with high detail. Additionally, its streamlined process facilitates faster production times and lower costs, making it more accessible for custom garment printing.

What role do companies like EazyDTF play in advancing DTF transfers?

Companies like EazyDTF are pivotal in advancing DTF transfers by investing in new technology and expanding operations. Their recent addition of large-format DTF printers enhances production capabilities, allowing for same-day printing services, which meet the increasing demand for quality DTF prints.

Why is Snuggle DTF significant for custom DTF transfers?

Snuggle DTF is significant as it offers a web-to-print platform specifically for businesses and resellers, streamlining the process of creating custom DTF transfers. This innovation makes it easier for companies to implement DTF technology into their garment printing services, improving overall efficiency.

What innovations can we expect in the future of DTF transfers and textile printing?

The future of DTF transfers in textile printing looks promising with ongoing advancements, such as Mimaki’s new UV DTF technology that expands the application of DTF beyond fabrics to stickers. As companies continue to invest in this printing method, we can expect greater versatility and new creative possibilities in the textile industry.

| Key Points | Description |

|---|---|

| What are DTF Transfers? | A printing method that transfers designs from a special film onto fabrics using heat and pressure. |

| Versatility | Can be applied to various materials like cotton, polyester, and blends for garments. |

| Time-Efficiency | Streamlined production process leading to quicker fulfillment times. |

| Cost-Effectiveness | Competitive production costs yield high profit margins for businesses. |

| Quality and Durability | Offers vibrant colors that resist fading with washes, enhancing garment lifespan. |

| Recent Innovations | Key developments by Snuggle DTF, EazyDTF, DTFPrinter, and Mimaki enhancing DTF capabilities. |

Summary

DTF Transfers represent a significant leap in the textile printing industry, merging innovation with practicality. As a highly versatile and cost-effective printing method, DTF technology is shaping the future of garment customization. Its unique ability to deliver vibrant, durable prints across a variety of fabrics makes it an appealing choice for both businesses and individual creators. With ongoing innovations from leading companies like Snuggle, EazyDTF, and Mimaki, the potential for DTF Transfers to revolutionize how we approach textile printing is immense. Businesses that embrace DTF technology will not only meet the demands of a dynamic market but also enhance their competitive edge.