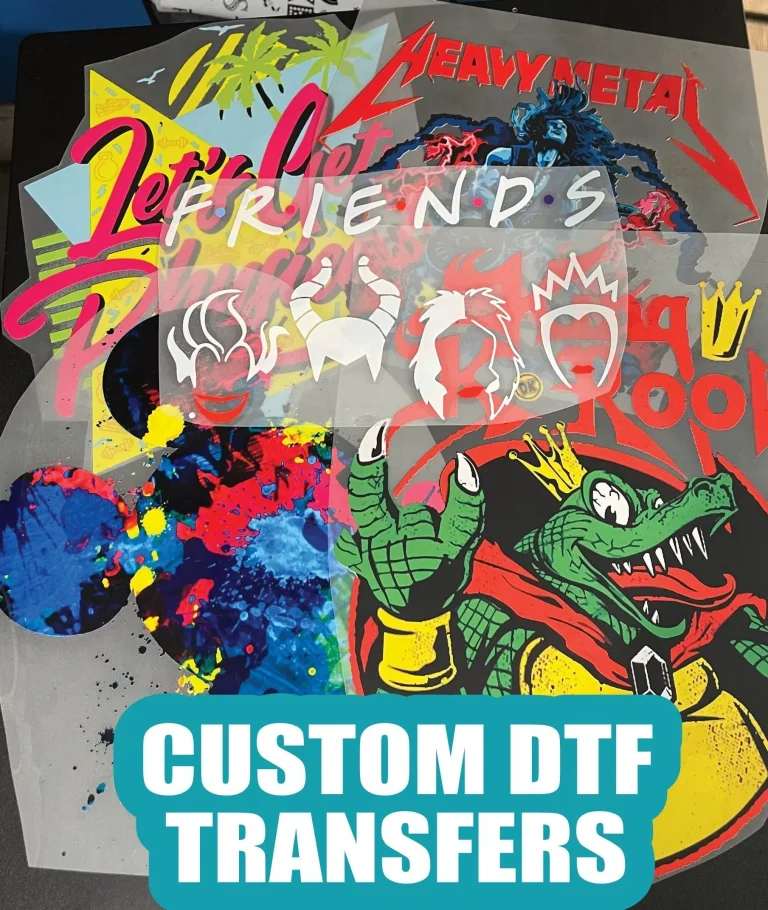

DTF transfers: Pros, Cons, and What to Expect in 2025

DTF transfers have emerged as a versatile and increasingly popular method for turning digital designs into high-quality fabric prints. For anyone evaluating custom apparel, understanding the key advantages and drawbacks—often discussed in terms of DTF transfer pros and cons—helps set expectations. This approach supports vibrant color, white underbase, and compatibility with a range of fabrics, which you’ll notice when exploring how DTF transfers work. From DTF printing on fabrics to a look at DTF vs screen printing, this overview helps you decide whether this method fits your project. By outlining practical considerations like cost, durability, and care, this intro sets the stage for deeper exploration of when this transfer method is the right choice.

In broader terms, this technique is often described as direct-to-film printing, or film-based transfer technology, a modern path for placing intricate artwork onto textiles. Using a clear PET film, special inks, and an adhesive powder, the process yields full-color images that can be applied to a wide range of fabrics. Compared with traditional screen printing, this approach is praised for flexibility, faster setup, and strong color reproduction on both light and dark materials. Understanding the mechanics—digital design on film, white underbase where needed, powder drying, and heat-press activation—helps buyers and makers forecast results and workflows.

DTF Transfers: How They Work and Why They Deliver Rich Color on Fabrics

DTF transfers explain the process from concept to craft: how DTF transfers work starts with preparing a digital design for fabric printing, then printing onto a PET film with a specialized printer capable of vibrant color and a solid white ink underbase. The white underbase is crucial for bright, opaque colors on dark fabrics, ensuring accurate color reproduction and sharp edges. After printing, an adhesive powder is evenly applied to the film, and a curing step fuses the powder to the film to create a durable printable transfer. Finally, the film is pressed onto the fabric with a heat press, transferring the inks to the textile as the design bonds to the fibers. This sequence yields a durable, full-color image that can stretch with the garment and withstand regular washing when properly executed.

DTF printing on fabrics offers versatility across a broad range of textiles while maintaining high fidelity in color and detail. Because the process starts with a digital print, you can reproduce complex artwork and photo-realistic imagery with gradients and fine lines that are often challenging for other methods. Proper curing and adherence to manufacturer guidelines for ink, film, and powder ensure a strong bond and longevity. For brands and hobbyists alike, understanding how DTF transfers work helps set realistic expectations for use, care, and wardrobe durability across cotton, blends, and some synthetic fabrics.

DTF Printing on Fabrics: Pros, Cons, and How This Compares to Screen Printing

DTF transfer pros and cons are an essential consideration for decision-making. On the positive side, DTF transfers deliver rich color, precise gradients, and the ability to render detailed artwork with solid white underbases that brighten on dark fabrics. The versatility across fabrics—cotton, blends, and some synthetics—makes DTF printing on fabrics appealing for diverse product lines and quick-turn projects. However, there are trade-offs, including upfront equipment and consumable costs, maintenance, and a potential tactile feel on some fabrics. Weighing these factors helps determine if DTF transfers align with your run sizes, budget, and desired fabric experiences.

When comparing DTF vs screen printing, the most relevant factors are run size, design complexity, and desired hand feel. DTF offers strong advantages for small runs and rapid design changes, avoiding screen setup costs and long lead times. In contrast, screen printing excels at very large orders and single-color or limited-color designs, often providing a softer hand when properly cured. For those evaluating DTF vs screen printing, it’s important to consider the total cost per piece, color complexity, and required durability. For many brands, DTF printing on fabrics delivers vibrant, durable results with flexibility for seasonal variations, while screen printing remains a robust option for high-volume, cost-efficient production.

Frequently Asked Questions

DTF transfers: What are the key DTF transfer pros and cons when printing on fabrics?

DTF transfers deliver vibrant color, smooth gradients, and a solid white underbase for dark fabrics, with broad compatibility across cotton, blends, and some synthetics. They’re cost-effective for small runs and offer relatively quick setup compared with screen printing. Cons include higher upfront equipment and consumable costs, ongoing maintenance, and a learning curve to optimize curing times and heat settings. Some users may notice a distinct hand on lightweight fabrics, and storage of films and powders requires proper handling to maintain quality.

How do DTF transfers work and how do they compare to DTF vs screen printing?

DTF transfers work by printing the artwork on a PET film with a white underbase, applying adhesive powder, curing, and then pressing the film onto fabric to transfer the inks. The result is durable, color-rich prints that can stretch with the fabric. When comparing DTF vs screen printing, DTF shines for small runs, complex multicolor designs, and fast design changes, while screen printing excels at large-volume orders with very bold, uniform colors and potentially a softer hand on certain fabrics. DTF printing on fabrics also benefits from white underbase for bright artwork on dark garments, whereas screen printing may require more setup for multiple colors.

| Aspect | Key Points |

|---|---|

| What is DTF transfers? | Direct-to-Film printing uses a PET film printed with vibrant color and a white underbase, then heat-pressed onto fabric to produce durable, high-quality prints. It works across fabrics such as cotton, blends, and some synthetics. |

| How DTF transfers work | A digital design is printed on PET film with a white underbase, adhesive powder is applied, the film is cured, and then the print is transferred to fabric with heat and pressure. The result is a color-rich print that can stretch with the fabric and endure regular washing when properly cured. |

| Pros of DTF Transfers |

|

| Cons of DTF Transfers |

|

| DTF Transfers vs Screen Printing |

|

| DTF vs Traditional Heat Transfer |

|

| What to Expect When You Start with DTF Transfers |

|

| Practical Tips for Great DTF Results |

|

| Common Mistakes and Troubleshooting |

|

| Care Instructions for DTF-Printed Garments |

|

| Applications and Real-World Use Cases |

|

Summary

DTF transfers offer a compelling blend of color quality, versatility, and practical value for apparel projects. They deliver vivid, durable prints that can be used on a wide range of fabrics, with relatively low setup for small runs compared with traditional screen printing. By understanding how DTF transfers work and following best practices for file prep, curing, and care, you can achieve professional results and scale your offerings across product lines. If you’re deciding between DTF transfers and other methods, this overview highlights key considerations to help you choose the right approach for your next project.