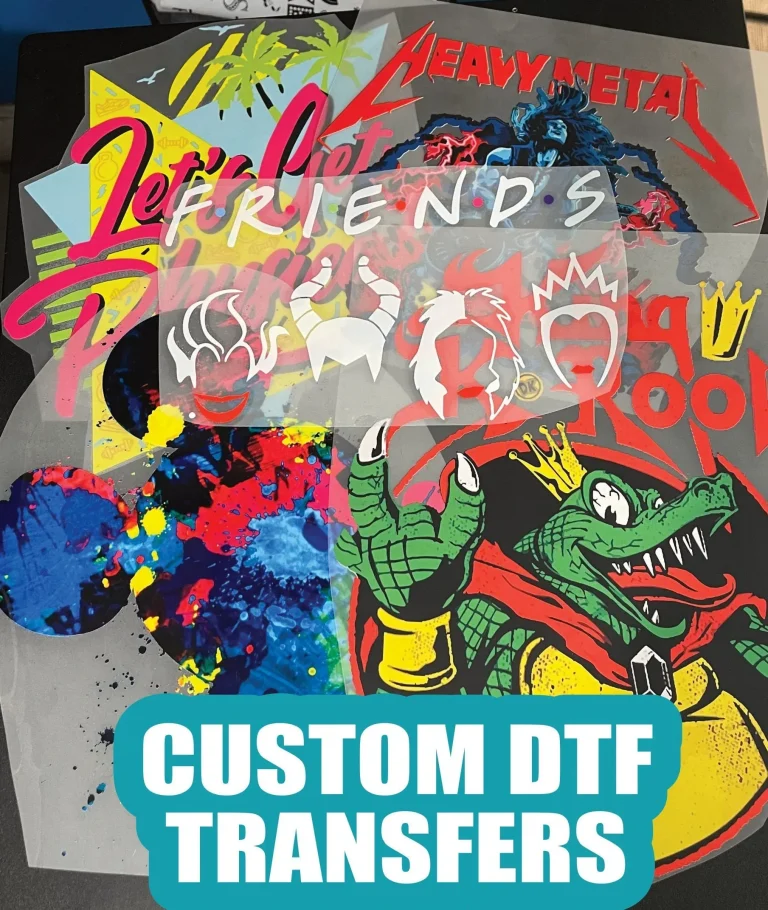

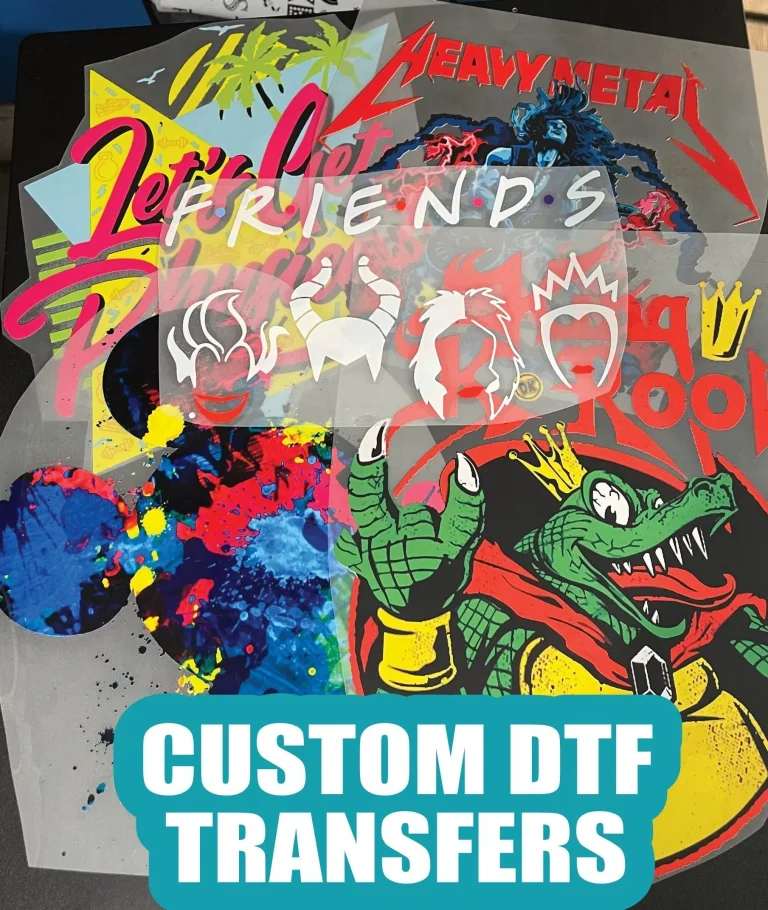

DTF transfers: Optimizing results with high-quality supplies

DTF transfers have emerged as a powerful method for decorating textiles, offering vibrant color, smooth gradients, and durable finishes. To maximize results, optimize the entire chain of DTF transfer supplies—from ink and powders to film and adhesive—so color accuracy in DTF transfers is consistent across fabrics. Premium DTF ink and powders—the best DTF ink and powders—translate into sharper prints, better saturation, and improved DTF printing quality across production runs. Calibrated DTF heat press settings and a repeatable workflow help secure uniform adhesion and stable finishes on different materials. Document test results and batch comparisons to build a library of references that supports reliable outcomes and stronger client confidence in DTF transfers.

Another way to describe this modern textile decoration approach is via digital textile transfer technology, where images are printed on a substrate and then applied to fabric. This method relies on the synergy of printer inks, curing powders, and a compatible film to deliver vivid color and durable hand feel. By focusing on material quality and process control, operators can achieve consistent results across garments, with attention to color fidelity and wash resistance. The workflow benefits from well-matched components, careful heat press timing, and standardized testing—concepts that align with Latent Semantic Indexing principles. In short, if you optimize the system—from supplies to settings—you unlock reliable, scalable prints that resonate with clients seeking vibrant, long-lasting graphics.

Understanding the Core of DTF Transfers: Materials, Mechanics, and Outcomes

DTF transfers rely on a stack of interdependent components: ink, powder, film, adhesive, and heat; the quality of each affects color, detail, and durability. In this system, the term DTF transfers refers to the final decorated fabric; achieving the look requires compatible supplies and precise process control. The base content described how good DTF supplies drive better results; this holds true across fabrics and designs, guiding you toward reliable production.

When one element underperforms, issues like color shifts, speckling, or poor adhesion can arise. By focusing on premium DTF transfer supplies and aligning printer settings, you establish a baseline that translates to consistent DTF printing quality across runs.

Choosing Premium DTF Transfer Supplies for Consistent Results

Selecting inks, powders, film, and adhesive with compatibility and performance is critical. Look for inks with wide color gamuts and good cohesion with the powder layer; choose powders with uniform granule size and quick tack. The broader concept here is that your DTF transfer supplies set the foundation for every print, and consistency matters.

Consider film curl, release properties, and adhesive bond across fabrics; build relationships with reputable suppliers who provide data sheets and support. This supports the best DTF ink and powders and reduces variability, boosting DTF printing quality across production runs.

Optimizing Color Management for Color Accuracy in DTF Transfers

Color accuracy in DTF transfers depends on printer calibration, RIP workflow, ink formulation, powder application, and heat press settings. Establish a standard test sheet including a color chart and grayscale to benchmark and compare results across sessions.

Document parameters and keep using the same DTF transfer supplies during tests to build a library of reference sheets. Over time, you’ll reduce guesswork and improve color reproduction, supporting color accuracy in DTF transfers overall.

Heat and Texture: Fine-Tuning DTF Heat Press Settings for Quality

Heat press parameters—temperature, pressure, dwell time—directly affect color fidelity and fabric feel. Too high heat can degrade colors; too little heat leads to poor adhesion and a stiff hand.

Develop a fabric-specific profile, test swatches, and record standard settings. Align heat press settings with film and adhesive to minimize edge lifting and texture inconsistencies, helping maintain high DTF printing quality.

Achieving Reliable Adhesion and Finish with Quality DTF Film, Adhesive, and Powders

Film quality influences curl, blistering, and edge lift; adhesives determine bond strength and any residue on the garment; powders influence how evenly the image coats and cures. Selecting reliable DTF transfer supplies helps prevent common defects that derail the finish.

Testing components within the same quality tier before switching parts reduces risk of color shifts or adhesion problems. This approach supports consistent color fidelity and finish across batches, reinforcing the value of premium DTF ink and powders.

Workflow and Quality Control: Building Repeatability into Every DTF Transfer

A documented standard operating procedure (SOP) for material selection, color management, print settings, powder application, curing, and post-processing creates a predictable workflow. When every team member follows the same steps and uses the same DTF transfer supplies, variability drops and overall DTF printing quality rises.

Regular reviews of the workflow, updates based on new supplies or techniques, and ongoing calibration keep your process current. Maintaining stable storage conditions and supplier reliability helps sustain color accuracy in DTF transfers and ensures long-term consistency.

Frequently Asked Questions

What are the essential DTF transfer supplies to maximize DTF printing quality?

Key DTF transfer supplies include high-quality DTF ink, compatible powders, a low-curl film, reliable adhesive, and appropriate heat press consumables. Investing in premium DTF transfer supplies helps achieve richer color, smoother gradients, and stronger wash durability, directly boosting DTF printing quality.

How can I improve color accuracy in DTF transfers using the best DTF ink and powders?

Use the best DTF ink and powders matched to your printer and film, run controlled test sheets with the same supplies, calibrate RIP color profiles, and document ink density and powder thickness. Keeping the same DTF transfer supplies across runs helps stabilize color accuracy in DTF transfers.

What DTF heat press settings are recommended to optimize transfers?

Start with manufacturer guidelines for temperature, time, and pressure, then fine-tune in small steps based on fabric type. Use a consistent DTF heat press settings protocol across batches and record the final values to maintain repeatability.

What common issues can arise with DTF transfers and how can premium supplies help?

Issues like color shifts, speckling, poor adhesion, or edge curling can occur when any component underperforms. Premium DTF transfer supplies—inks, powders, film, and adhesive—offer more consistent quality, reducing these problems. Always run test swatches and align curing parameters.

How do I build a repeatable DTF printing workflow for consistent results?

Document a standard operating procedure covering material selection (DTF transfer supplies), color management, print settings, powder application, curing, and post-processing. Using the same DTF transfer supplies and reviewing the workflow regularly minimizes variability and maintains DTF printing quality.

What should I consider when sourcing DTF transfer supplies to maximize finish and durability?

Look for reliable brands with data sheets, samples, and clear usage guidance. Ensure proper storage for inks and powders, stable environmental conditions, and strong support. Premium DTF transfer supplies typically deliver better color fidelity, wash durability, and consistent results.

| Topic | Summary |

|---|---|

| Value and impact of DTF transfers | DTF transfers decorate textiles with vibrant color, smooth gradients, and durable finishes. Optimizing the process yields consistency across batches, fabrics, and designs; good DTF supplies drive better results (inks, powders, film, adhesive, and heat press consumables influence color accuracy, finish, and wash durability). The central idea is to focus on materials and process control to elevate printing quality. |

| Key components and their influence | The transfer’s final look hinges on compatible film, secure adhesive, color inks, and coating powder. Each element affects color accuracy, finish, and longevity; the wrong combination can cause color shifts, speckling, poor adhesion, or a stiff hand feel. |

| Role of premium DTF transfer supplies | Premium supplies create a solid foundation for prints: ink improves color reproduction and saturation; powders promote even adhesion; film reduces curl; adhesive ensures strong bonding. All components influence perceived quality, and dependable supplies paired with a sound process yield predictable results. |

| Choosing the right DTF transfer supplies | Quality and compatibility matter. Look for inks with wide color gamuts and good cohesion with powder; powders with uniform granule size and quick tack; film with low curl and strong release; adhesives that bind well without residue; finishes durable after washing; and a consistent brand/supply chain. |

| Color accuracy and repeatability | Color accuracy depends on printer calibration, RIP/workflow, ink, powder, and heat press settings. Establish a baseline with a test sheet (color chart, grayscale, common design elements). Use the same supplies for tests and document parameters (ink density, powder thickness, curing time, temperature, pressure) to build a library of reference sheets. |

| Practical tips for optimization | Pre-test materials, calibrate printer and RIP, control the powder layer, optimize heat press parameters, use test swatches for each batch, and handle fabrics correctly (pre-wash/guidelines). Regularly test and document settings to catch issues early. |

| Common challenges and premium supplies | Low-quality inks/powders can cause muddy colors; substandard film may curl or misalign; adhesives with inconsistent tack cause uneven transfer. Prioritize good DTF transfer supplies and test alternative components within the same quality tier when issues arise. |

| Sourcing and maintenance | Source from trusted suppliers with technical data sheets and usage guidance; request sample packs; store powders and inks properly; maintain a stable environment; implement routine cleaning and maintenance for printers and curing equipment to prevent contamination. |

| Workflow optimization and cost considerations | Develop a documented standard operating procedure covering material selection, color management, print settings, powder application, curing, and post-processing. A repeatable workflow reduces variability. Higher upfront costs can be offset by less waste, fewer reprints, faster production, and stronger client relationships, especially when premium supplies deliver better color fidelity and durability. |

Summary

Conclusion: