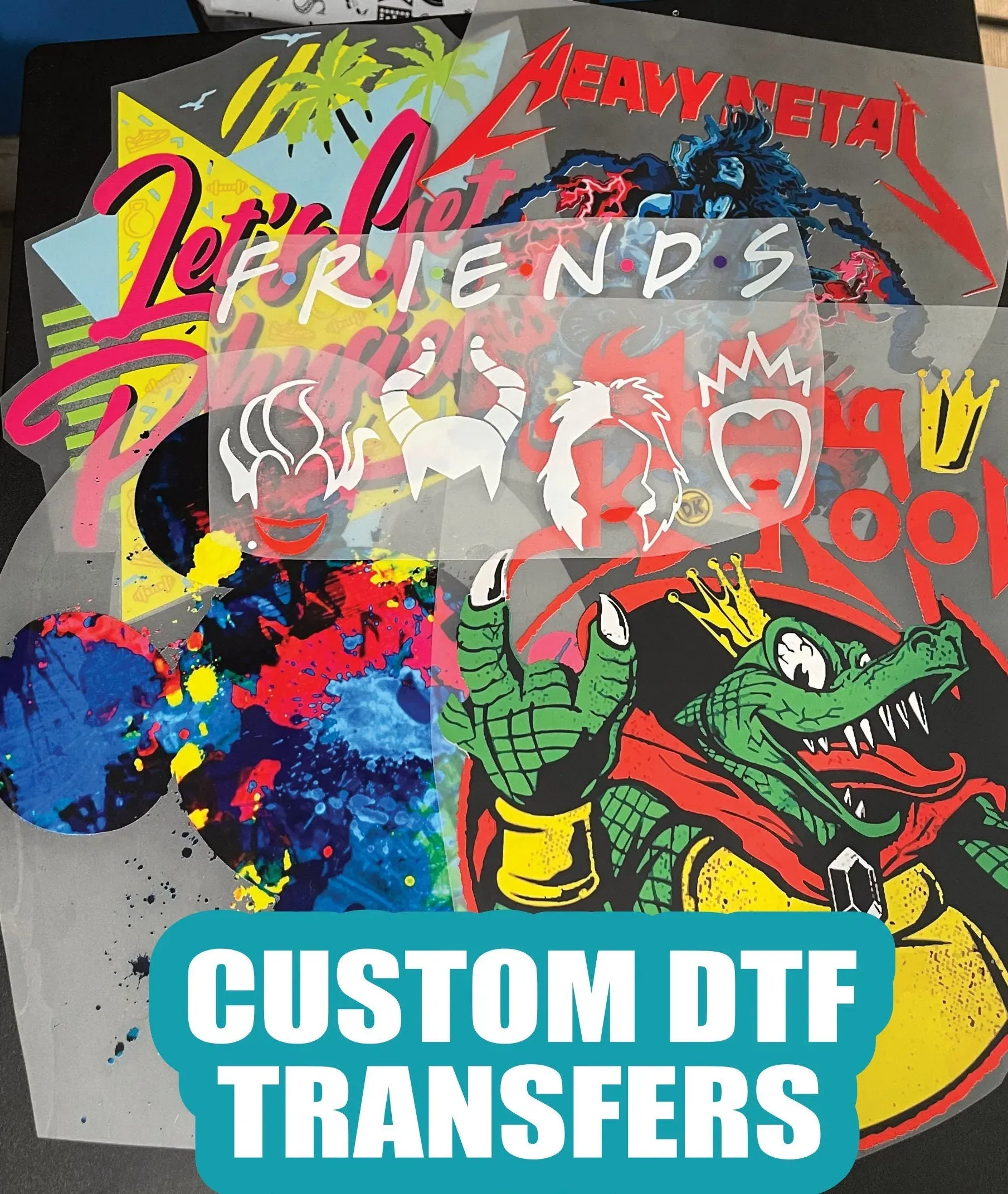

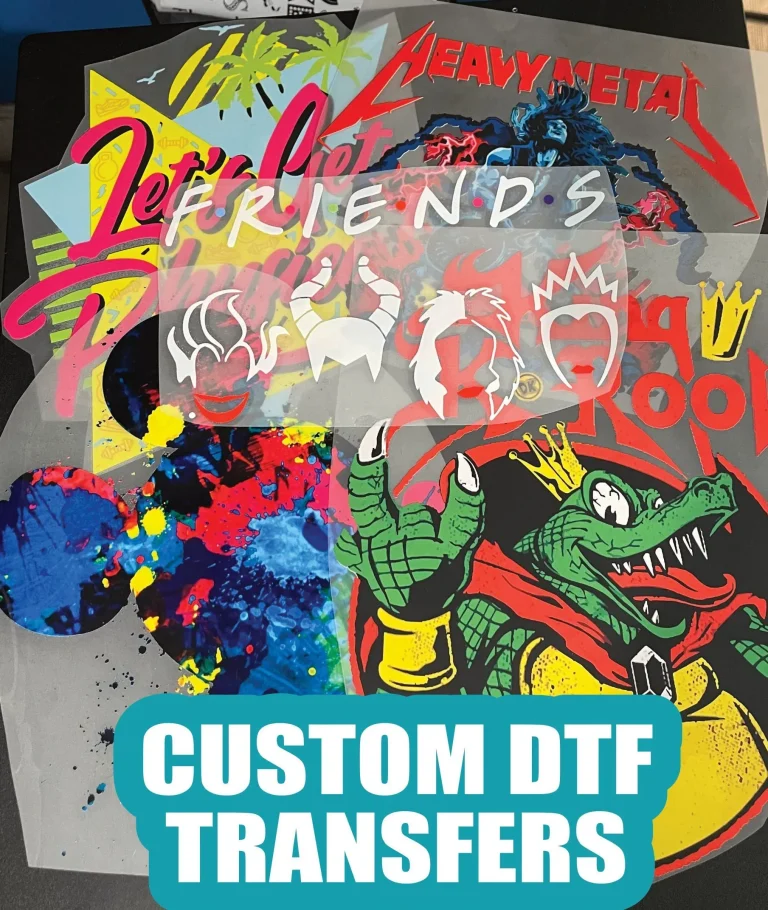

DTF Transfers: Maximize Your Profits in Garment Printing

In the rapidly evolving landscape of garment printing, **DTF transfers** are emerging as a revolutionary technology that is capturing the attention of businesses. Direct-to-Film (DTF) technology streamlines the garment printing process while providing unmatched affordability and versatility. With the ability to print vibrant, durable designs on a variety of fabric types, DTF printing is quickly becoming a preferred print method for custom apparel. The benefits of DTF printing, including lower setup costs and faster production times, make it an attractive choice for both startups and established companies looking to enhance their offerings. As more businesses discover the profound potential of DTF transfers, they are poised to transform the future of garment printing.

Direct-to-Film solutions, commonly referred to as DTF printing, represent a breakthrough in the world of custom textile decoration. This innovative print technology positions itself as a strong contender against traditional methods like screen printing and sublimation, offering unique advantages that meet the needs of modern businesses. By employing specialized film to transfer designs onto garments, these methods not only promote efficient production but also ensure high-quality, long-lasting results. As more companies pivot toward DTF technology, understanding its growing significance and the myriad of possibilities it presents is essential for anyone in the garment printing industry. With its emphasis on versatility and quality, DTF printing is set to reshape custom apparel production.

The Rise of Direct-to-Film (DTF) Technology in Garment Printing

As businesses in the garment printing industry seek effective solutions to enhance productivity, **Direct-to-Film (DTF) technology** has come to the forefront. This innovative method involves printing vibrant designs onto a special film, which are then heat-pressed onto various fabrics. The growth of DTF technology marks a shift from traditional print methods like screen printing, primarily due to its adaptability across different material types. Companies are now recognizing the ease with which they can incorporate DTF into their operations, streamlining the printing process and meeting diverse customer demands.

Furthermore, the adoption of DTF technology is not just a trend; it signifies a pivotal change in how businesses approach garment printing. The versatility of DTF allows for a broad range of fabric compatibility, making it ideal for custom apparel production. Retailers are increasingly seeking ways to differentiate themselves, and DTF offers unique designs and high-quality prints that cater to this need. The ongoing developments in this sector reveal that DTF will play an essential role in the future of garment printing.

Exploring the Benefits of DTF Printing

The **benefits of DTF printing** are plentiful, making it an attractive option for both new and established garment printing businesses. One major advantage is cost efficiency; DTF setups require significantly lower initial investment compared to conventional methods. For start-ups or smaller operations, this allows for greater flexibility in product offerings without the financial burden typical of larger scale print methods.

Moreover, DTF printing excels in producing high-quality and durable designs. Unlike traditional methods that might cause prints to crack or fade after multiple washes, DTF transfers are designed for longevity. This durability not only satisfies customers but also reduces returns and increases profit margins. By ensuring that each garment retains its integrity over time, businesses can cultivate a loyal customer base.

Comparative Analysis: DTF vs. Traditional Printing Methods

When comparing DTF transfers with traditional printing methods like screen printing or sublimation, it becomes evident that DTF holds several competitive advantages. One of the most significant distinctions is its ability to print on various materials, including cotton and blends, compared to the limitations that often accompany screen printing. This feature provides businesses with the flexibility to cater to a wider audience by diversifying their product lines.

Additionally, the speed of the DTF printing process is noteworthy. While traditional methods often involve intricate setup processes, DTF allows for quicker transitions from design to final product. This efficiency enables businesses to respond promptly to market trends and customer demands for custom apparel, ultimately leading to improved customer satisfaction and increased sales.

How DTF Transfers Enhance Custom Apparel Production

The demand for custom apparel has grown exponentially, with consumers seeking unique, personalized designs. DTF transfers play a crucial role in fulfilling this demand, providing businesses with the capability to produce intricate designs quickly and cost-effectively. The technology not only offers vibrant color reproduction but also supports the production of small batch runs, making it ideal for custom orders.

Moreover, the simplicity of the DTF process significantly reduces the learning curve for new operators, allowing businesses to scale their custom apparel offerings rapidly. With less technical expertise needed than traditional methods, teams can be trained more efficiently, leading to increased production rates and faster turnaround times. This capability positions businesses to seize opportunities in the custom apparel market more proactively.

Recent Innovations in DTF Technology

The advancements in **DTF technology** are noteworthy, particularly concerning new trade services and capacity expansions within the market. Companies like Snuggle and EazyDTF are making significant investments to enhance their DTF capabilities, ensuring that they can meet the increasing demand for efficient and high-quality garment printing. These developments not only indicate a robust growth trend within the DTF sector but also signal a shift in industry standards.

As these companies innovate and expand their operations, businesses utilizing DTF services gain access to sophisticated technology that rivals traditional methods. The improvements in printer technology and film formulations contribute to better production processes, leading to higher quality outputs and customer satisfaction. The rapid evolution of DTF technology ensures that businesses remain competitive and equipped to handle the complexities of modern garment printing.

Cost-Effectiveness of DTF Transfers for Small Businesses

For entrepreneurs in the garment printing industry, cost-effectiveness is a crucial factor. DTF transfers are particularly appealing to small businesses as they lower the overall setup costs associated with printing. The streamlined workflow of DTF technology allows business owners to focus their resources on creativity and customer service rather than managing expensive production overheads.

Additionally, the ability to produce short runs without sacrificing quality is another financial boon. Smaller operations can capitalize on niche markets or special orders, offering a range of customizable products without the financial risk associated with larger print runs. This flexibility empowers businesses to explore diverse opportunities and respond dynamically to market demands.

Frequently Asked Questions

What are the main benefits of using DTF transfers in garment printing?

DTF transfers offer several key benefits in garment printing, including versatility to print on various fabric types such as cotton and blends, exceptional quality with vibrant colors and durability against fading, cost-effective setup for smaller runs, and a simplified process that leads to quicker turnaround times. These benefits make DTF technology a compelling choice for businesses looking to optimize their garment printing operations.

How does DTF printing compare to traditional print methods like screen printing?

DTF printing has distinct advantages over traditional methods like screen printing. It allows for printing on a wider range of materials, not just polyester, making it suitable for diverse product lines. Additionally, DTF transfers have lower setup costs, especially for smaller production runs, and offer higher quality prints that resist wear over time, making this method an efficient and cost-effective alternative.

Can DTF transfers be used for custom apparel designs?

Yes, DTF transfers are ideal for custom apparel designs. The technology supports detailed, vibrant prints on various fabric types, allowing businesses to create personalized garments tailored to customer preferences. This customization capability enhances product offerings and meets the growing demand for unique apparel.

What is the process involved in applying DTF transfers to garments?

The DTF transfer process involves printing designs onto a special film, which is then heat-pressed onto the garment. This straightforward technique simplifies production, reducing complexity and skill requirements, thus enabling quicker production times and enhancing operational efficiency for businesses.

Are DTF transfers durable for long-term use on garments?

Absolutely, DTF transfers are known for their durability. The prints maintain their quality, resisting fading and cracking even after multiple washes. This longevity minimizes returns and enhances customer satisfaction, making DTF transfers a reliable choice for businesses focused on quality.

What kind of businesses can benefit from adopting DTF technology for garment printing?

Businesses ranging from startups to established garment printers can benefit from adopting DTF technology. Especially beneficial for companies specializing in custom apparel or small to medium production runs, DTF transfers provide cost-effective and versatile printing solutions that cater to various customer needs, enhancing overall profitability.

| Key Points | Details |

|---|---|

| Introduction | DTF transfers are an innovative printing solution enhancing productivity and maximizing profits. |

| Understanding DTF Transfers | Involves printing on a specialized film for heat pressing onto garments, competing with traditional methods. |

| New Trade Services | Snuggle DTF provides streamlined DTF processes for commercial clients. |

| Capacity Expansion | EazyDTF expands with new printers to meet increasing demand. |

| Comparative Advantages | DTF transfers can be used on more fabric types compared to sublimation. |

| Key Advantages | |

| Versatility | DTF can print on a variety of fabrics including cotton and blends. |

| Quality and Durability | DTF prints resist fading and cracking, ensuring long-lasting quality. |

| Cost-Effective Setup | Lower setup costs make DTF ideal for smaller runs. |

| Ease of Process | Simpler processes lead to quicker turnaround times. |

Summary

DTF transfers are revolutionizing the garment printing industry with their unique advantages. This innovative printing method not only enhances productivity but also allows businesses to produce high-quality prints across a wider variety of fabrics compared to traditional techniques. With lower setup costs and simpler processes, DTF transfers represent a cost-effective solution for businesses of all sizes, making them an attractive option for those looking to improve their printing capabilities. As industry leaders invest in the technology, it’s clear that DTF transfers are redefining standards in garment printing, making them not just a trend but a future necessity for businesses striving to stay competitive.