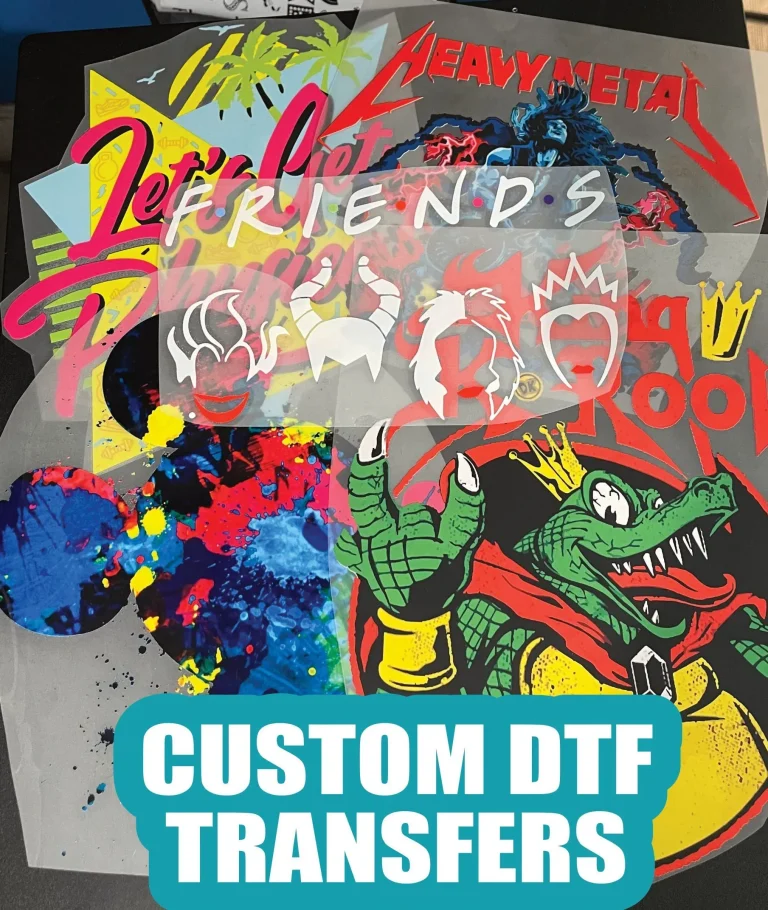

DTF transfers have revolutionized textile decoration by delivering vibrant colors and durable finishes. For apparel, accessories, or promo items, choosing the right DTF transfer materials and understanding the DTF film and powder is essential. The DTF curing process plays a critical role in how the final print feels and lasts when washed. Optimizing heat-press settings and using high-quality DTF printing materials ensures color fidelity and a soft hand. This guide introduces the key materials, the curing steps, and practical tips to achieve consistent, long-lasting results.

In other words, this approach is a film-based transfer method that uses a PET film as the carrier. Commonly referred to as direct-to-film printing, the process relies on pigment inks, a bonding powder, and a curing step before heat pressing onto fabric. Alternative terms you may encounter include direct-to-film application, film-to-garment transfer, and PET film printing technology, all pointing to the same family of processes. Understanding these synonyms helps you navigate suppliers and resources while focusing on color fidelity, durability, and wash performance.

Choosing DTF transfers: A Practical Guide to DTF Film, Inks, and Powder

Selecting DTF transfer materials sets the foundation for reliable color and adhesion. Start by evaluating DTF transfer materials as a cohesive system—DTF film and powder with compatible inks and bonding agents—and ensure they are designed to work together with your printer and heat-press setup. This alignment reduces variability and helps reproduce sharp detail, accurate color, and durable hand-feel across lots.

Consider fabric type and processing conditions when choosing DTF transfer materials. Cotton, polyester, and blends respond differently to heat and moisture, so check the recommended ranges for curing temperatures and press times on the fabrics you plan to use. Proper handling and storage of DTF printing materials, especially film and powder, also protect performance and longevity.

Mastering the DTF curing process and DTF heat press settings for durable, vibrant prints

Understanding the DTF curing process is essential to a lasting transfer. After printing, powder is applied to the wet ink, then fused with heat to create a robust adhesive layer on the film. Cooling and inspection ensure a uniform surface before transfer. When the curing is done well, the final print delivers consistent color fidelity and wash-fastness when applied to fabric.

Optimizing DTF heat press settings is critical for durability. Temperature, time, and pressure must be calibrated to the film, ink, and fabric. Typical ranges—such as curing around 120-160°C for the powder, and transfer around 160-170°C for 12-20 seconds—are guidelines; always consult the film maker. Use test transfers to lock in precise DTF heat press settings for your substrates, avoid scorching, and ensure a clean finish with a brief cold peel if recommended.

Frequently Asked Questions

What DTF transfer materials should I choose for reliable results, and how do DTF film and powder and the curing process influence the transfer outcome?

For reliable results, select DTF transfer materials that are designed to work together within the DTF printing materials ecosystem—specifically, choose compatible DTF film and powder. The curing process activates the powder and stabilizes the coating on the film, which is essential before transfer. Always verify compatibility among the film, powder, and recommended DTF printing materials from the manufacturer, and run a few test transfers to confirm color accuracy, adhesion, and wash durability.

How do DTF curing process and DTF heat press settings affect transfer quality across different fabrics, and what role do DTF transfer materials play?

The DTF curing process and DTF heat press settings directly impact transfer quality on each fabric type. Use fabric-specific curing temperatures and transfer times and apply consistent medium pressure during pressing to avoid image distortion. Always consult the film maker’s guidelines and maintain standardized DTF transfer materials (film and powder) to ensure consistent results; test on representative samples when changing material batches.

| Aspect |

Key Points |

| Introduction |

- DTF transfers offer high color vibrancy and durable finishes for textiles.

- Understanding the materials and curing process is essential for apparel, accessories, or promotional items.

- The right combination of materials, curing, and heat-press settings differentiates flawless prints from disappointing ones.

|

| What Are DTF Transfers and Why Materials Matter? |

- DTF transfers are made by printing on PET film with pigment inks, applying bonding powder, curing, then transferring the image to fabric with heat and pressure.

- Three core pillars: film and inks, powder/adhesive, and curing/transfer steps.

|

| Choosing the Right DTF Transfer Materials |

- DTF film and PET film provide the carrier for the print and should allow clear transfer and color accuracy.

- DTF inks are pigment-based for color density and wash-fastness; consistency matters.

- Printing materials/substrates include liners and protective layers that affect how the image sits on fabric.

- Powder/adhesive bonds the print to fabric when heat is applied.

- Curing equipment and settings (dryer/heat source) are needed to fuse the powder before transfer.

|

| How to Pick DTF Transfer Materials That Work Together |

- Compatibility: Ensure the film, inks, and powder are marketed for DTF and designed to work with each other.

- Fabric compatibility: Different fabrics (cotton, polyester, blends) have unique heat and moisture handling. Check material specs for recommended curing temperatures and press times on the fabrics you plan to use.

- Print quality: Look for inks with good color fastness, a wide color gamut, and stable drop sizes to reproduce detailed designs on the film.

- Handling and storage: DTF materials can be sensitive to humidity and temperature. Store film and powders in a controlled environment to maintain performance.

|

| The DTF Curing Process: From Powder to Transfer |

- Powder application: after printing, the printed film is dusted with polymer powder. The powder adheres to the sticky areas of the wet ink, forming a uniform coating that will bond to fabric.

- Powder curing: The coated film is cured with a heat source to melt and fuse the powder onto the film. This step eliminates loose powder and ensures that the adhesive layer is evenly distributed.

- Cooling and inspection: Once cured, allow the film to cool briefly and inspect for any dusting or uneven areas. A uniform, powder-coated surface is essential for consistent transfers.

- Transfer with heat: The final step uses a heat press to transfer the design onto the garment or substrate. Correct heat, time, and pressure settings are crucial for a durable result.

|

| Optimal Temperature and Time Ranges (Guidelines) |

- Curing temperature: Typically around 120-160°C (250-320°F) for a short period to fuse the powder without scorching the film.

- Transfer temperature and time: Often in the range of 160-170°C (320-338°F) for 12-20 seconds with medium pressure, followed by a brief cold peel or a post-press if recommended by the film maker.

- Pressure: Consistent, moderate pressure generally yields the most even transfer. Too little pressure can lead to incomplete bonding; too much can cause image distortions.

|

| Why Curing Affects End-Use Quality |

- Durability, color fidelity, and wash-fastness depend on proper curing; cured powder forms a robust layer that bonds with garment fibers during heat transfer.

- Incomplete curing can cause a powdery feel, snagging, or early cracking when stretched or washed.

- Over-curing or overheating can alter pigment density, cause gloss differences, or reduce film flexibility on curved areas.

|

| Practical Tips for Great DTF Transfers |

- Use fresh powder and store in a dry place to avoid clumping or moisture absorption, which can affect bonding.

- Calibrate your dryer or curing station so the powder fuses evenly across the film—avoid hot spots that cause uneven curing.

- Run small test transfers when changing any material (film, ink, or powder) to confirm compatibility before producing larger runs.

- Keep the transfer area clean and free of dust; debris on the film can cause imperfect adherence or misregistration.

- Align garments carefully before pressing. Misalignment can negate the benefits of vibrant color and crisp outlines.

|

| Common Issues and Troubleshooting |

- Uneven bonding: Check powder coverage and ensure proper curing. Uneven powder with hot spots can create adhesive gaps.

- White edges or halos: This often results from improper pre-press or misalignment. Trim or re-align precisely and ensure no moisture on fabric.

- Cracking or peeling after washing: Revisit curing temperature and time, and verify your heat-press settings for the fabric you use.

- Color shifts or dullness: Ensure inks are compatible with your film and calibrate the color profile in your printer to account for the working gamut.

|

| Best Practices for Longevity and Consistency |

- Standardize the material chain: Use a consistent set of DTF transfer materials (film, inks, powder) across jobs to reduce variability.

- Pre-press and moisture control: Pre-pressing removes moisture from the fabric, improving adhesion and reducing warp.

- Temperature and humidity control in storage: Keep films and powders in a climate-controlled environment to preserve performance.

- Documentation and testing: Record your process parameters for each material batch and fabric type. Maintain a small library of test transfers to reference when scaling production.

|

| Applications and Market Trends |

- DTF transfers are widely used for apparel branding, sportswear customization, event merchandise, and fashion items.

- The ability to reproduce vivid gradients and intricate details makes DTF particularly attractive for designs that require a wide color range and soft hand-feel.

- Materials quality and curing discipline are the main drivers of success in this field. As technology evolves, manufacturers are releasing more specialized DTF transfer materials—films designed for stretch fabrics, powders with improved bonding characteristics, and inks with enhanced wash durability—expanding the possibilities for creators and brands alike.

|

Summary

DTF transfers offer a compelling blend of color fidelity, durability, and versatility across fabrics. By understanding and aligning the right materials, curing processes, and heat-press settings, designers and manufacturers can achieve consistent, professional results on apparel, accessories, and promotional items. The key to success lies in choosing compatible film, inks, and powder, properly curing, and documenting parameters for repeatability. As the field evolves, ongoing refinement of materials and workflows ensures longer-lasting prints that withstand washing and wear.