DTF Transfers: How to Create Stunning Designs Easily

DTF transfers, or Direct to Film transfers, have revolutionized the way we approach high-quality fabric printing, making it easier than ever to create stunning designs. With its ability to apply vibrant graphics onto various fabrics, this innovative method offers a versatile solution for both amateur crafters and professional designers alike. As you explore how to create DTF designs, you’ll discover the seamless DTF printing process that ensures durability and vivid color output. From selecting the right custom DTF transfers to understanding the essential DTF transfer materials, this guide covers all the necessary steps to elevate your fabric printing skills. Let’s dive into the captivating world of DTF transfers and unlock your creative potential!

When it comes to modern textile arts, Direct to Film (DTF) methodologies are increasingly being favored for their efficiency and quality. These transfers, also known as DTF prints, utilize a unique printing approach where designs are infused onto a specially coated film before being applied to fabric. This technique not only ensures superb color vibrancy and detail, but it also allows for application across a diverse array of materials. As you embark on your journey to master DTF prints, familiarizing yourself with the associated tools and processes will set the stage for producing bespoke designs that stand out. Embrace the artistry of DTF techniques and bring your creative vision to life!

Understanding the DTF Printing Process

The DTF printing process is a meticulous yet straightforward methodology that combines creativity with technology. This technique begins by designing your artwork with precision software, ensuring that every detail reflects your vision. Once your design is completed, you print it onto a special DTF transfer film using a DTF printer. The printing employs vibrant inks that deliver rich colors and high-resolution outputs, which are crucial for captivating designs.

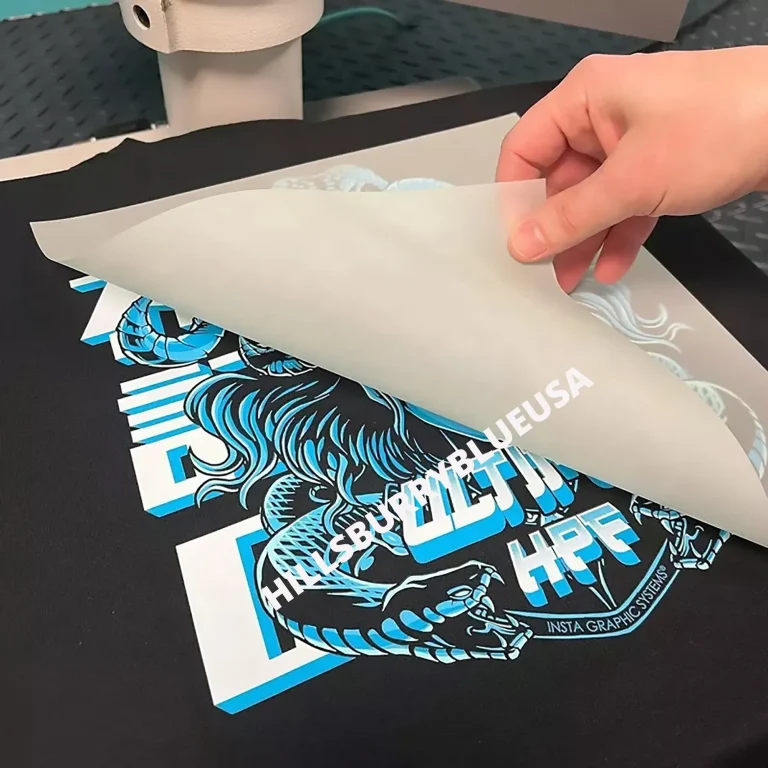

After printing, the next step involves applying adhesive powder while the ink is still wet. This adhesive is not merely a bonding agent; it plays an essential role in ensuring the longevity and durability of the final product. Once the adhesive is applied, a heat source, such as a heat press, is used to cure the design, solidifying the adhesive into a robust bond with your fabric. This process not only guarantees a dynamic overall appearance but also enhances the wearability of the design on various fabric types.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process involves printing high-quality designs onto a special film using a DTF printer. Once printed, adhesive powder is applied, and the design is heat transferred onto various fabrics, resulting in vibrant and long-lasting prints.

How do I create DTF designs for my projects?

To create DTF designs, use design software like Canva or Adobe Illustrator to craft your artwork. Ensure the design is saved in the correct format, and print it using a DTF printer on the appropriate film for optimal results.

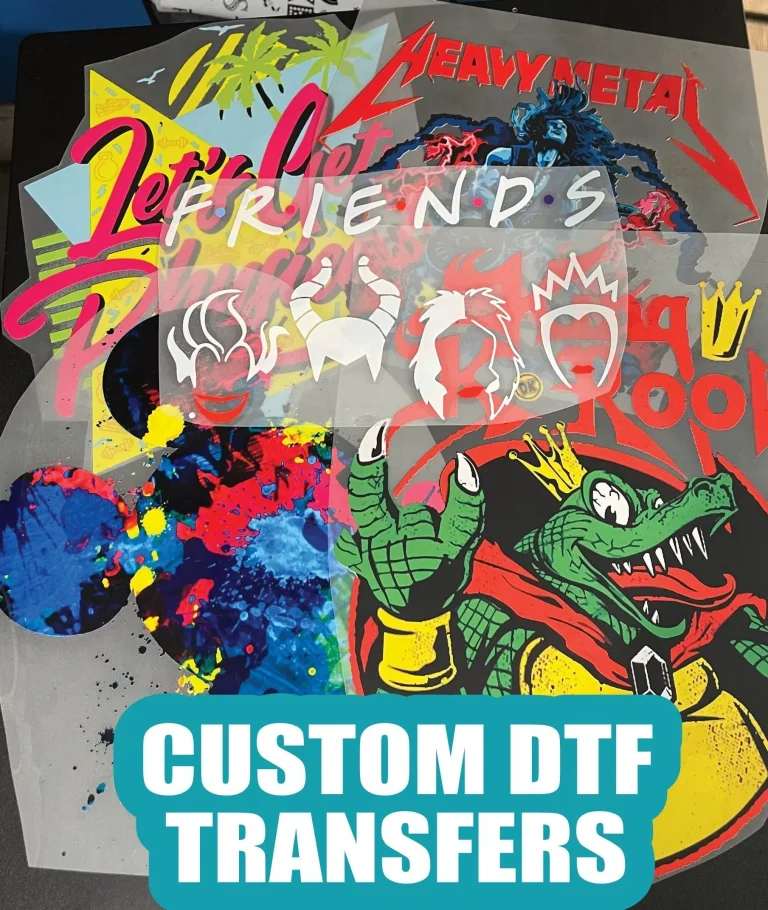

What materials do I need for custom DTF transfers?

For custom DTF transfers, you will need a DTF printer, high-quality DTF transfer film, a heat press machine, adhesive powder, and design software to create your artwork.

Can I use DTF transfers on any type of fabric?

Yes! DTF transfers are versatile and can be applied to a wide variety of fabrics, including cotton, polyester, and blended materials, making them ideal for many projects.

What are the advantages of using DTF transfer materials?

DTF transfer materials offer advantages such as durability, vibrant colors, ease of use, and compatibility with various fabrics, making them a popular choice among crafters and designers.

How can I troubleshoot common issues with DTF transfers?

To troubleshoot DTF transfers, ensure proper heat and pressure settings on the heat press, use high-resolution images for printing, and check printer settings to avoid fading or air bubbles in the transfers.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF transfers allow high-quality designs to be printed on a special film and transferred to fabrics. They are known for durability and vibrant colors. |

| Benefits of DTF Transfers | Durability, versatility across fabric types, vivid color output, and ease of use make DTF transfers appealing for creators. |

| Required Materials | DTF printer, transfer film, heat press machine, adhesive powder, design software. |

| Step-by-Step Process | 1. Design artwork, 2. Print on DTF film, 3. Apply adhesive powder, 4. Cure adhesive, 5. Cut transfer, 6. Heat press onto fabric, 7. Peel film. |

| Tips for Success | Use high-resolution images, ensure color matching with printer settings, and experiment with fabrics and designs. |

| Common Issues | Issues like designs not adhering or faded prints can be resolved by checking settings and using even pressure during application. |

Summary

DTF transfers present a unique method for transferring vibrant designs onto fabric, making them a popular choice for both beginners and experienced crafters alike. The ease of use, durability, and broad fabric compatibility of DTF transfers ensure that users can create professional-quality designs with minimal effort. With the right materials and techniques, your creativity can shine through every project. Explore the world of DTF transfers, where you can turn your artistic visions into stunning reality.