DTF Transfers: From Design to Durable, High-Quality Prints

DTF transfers have transformed how designers bring vibrant artwork to garments, delivering durability that rivals traditional screen prints while offering a soft hand and broad fabric compatibility. By adopting direct-to-film printing workflows, creators print onto PET transfer film, layering white and color inks to achieve bright images on a range of fabrics, from cotton tees to performance blends, with consistent color density and edge crispness. A fine layer of adhesive powder is applied after printing and then cured, where heat, time, and carefully controlled curing conditions bond the ink to the textile, forming a self-contained transfer that withstands repeated washing. The transfer sheet is trimmed, aligned on the garment, and prepared for application with protective sheets, alignment aids, and precise pressure to safeguard the print and ensure repeatable results across batches. With a well-tuned workflow and proper printer calibration, you can expect vivid color, sharp edges, and durable results that help brands deliver reliable, long-lasting apparel.

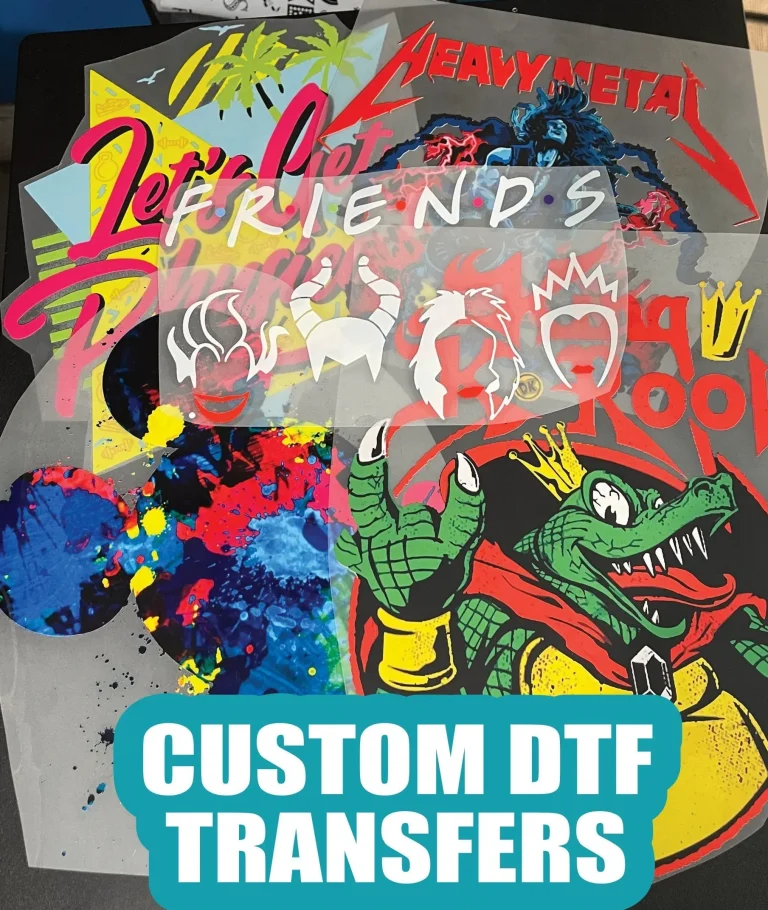

A film-based method for garment decoration uses digitally printed artwork that is prepared on a clear transfer sheet before being applied to fabric. This approach, often described as a film-coated, modern process, relies on precise ink layering, a post-print powder, and controlled heat to achieve durable color on a wide range of textiles. By framing the technique as a flexible option for small runs and custom designs, designers can optimize color management and workflow while expanding the fabrics you can decorate.

DTF transfers: Mastering direct-to-film printing for durable prints

DTF transfers offer a durable, vibrant option for decorating garments, and they are powered by direct-to-film printing technology. By printing onto a PET transfer film using white ink as a base, designers can achieve bold colors on dark fabrics and a soft hand feel once transferred. The process relies on a precise sequence of the transfer film, DTF powder, and controlled heat press conditions to lock the design into the fabric for durable prints.

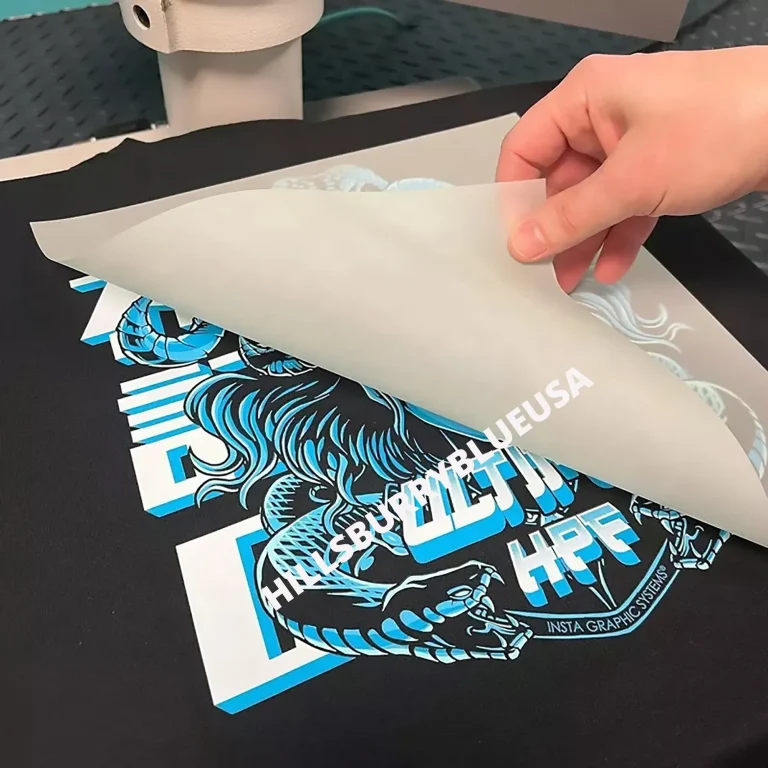

Understanding the full workflow—from design and prepress to curing, alignment, and post-press care—helps reduce waste and ensure color fidelity. Use a color managed workflow and ICC profiles to optimize direct-to-film printing results, and plan the white ink layer so the light areas align with the final garment. Proper curing of the DTF powder is critical for wash durability and edge crispness during the heat press transfer.

Optimizing the direct-to-film printing workflow for consistent results

To achieve consistent results with direct-to-film printing, invest in a reliable heat press, a quality transfer film, and a printer with stable white ink performance. Calibrate your printer and RIP workflow to maximize color accuracy, and use color charts and consistent lighting when evaluating proofs. A disciplined workflow helps ensure durable prints across a wide range of fabrics.

Practical fabric guidance keeps results predictable: cotton fabrics often deliver rich color and strong adhesion, while polyesters may require shorter dwell times due to heat sensitivity. For blends, test on swatches to determine the best balance of temperature and time. When working with dark fabrics, ensure the white base is tuned to maximize opacity, and always verify the adhesive cure with the heat press and transfer film to preserve wash durability of the final result.

Frequently Asked Questions

What are DTF transfers and how does direct-to-film printing create durable prints on fabric?

DTF transfers, or direct-to-film printing, involve printing your design onto a PET transfer film using a DTF printer equipped with white ink and color inks. After printing, an adhesive powder is applied and cured, creating a self-contained transfer sheet. The sheet is then placed on the garment and pressed with a heat press at the recommended temperature and time. When correctly executed, the combination of the transfer film, DTF powder, and proper curing yields durable prints that withstand multiple washes and maintain color vibrancy on a wide range of fabrics.

What are best practices to prevent common issues in DTF transfers and maximize durability?

Use a quality transfer film and reliable DTF powder, and follow a color-managed workflow from design to print. Pre-press the garment, align carefully, and cover with a protective sheet. Use a heat press at around 150–160 C (302–320 F) for 12–15 seconds with even pressure. Ensure the powder is fully cured to promote strong adhesion and avoid hotspots that can cause cracking, peeling, or color bleed. Peel at the recommended stage (hot or cold), and let the garment cool before washing. Proper care and curing are essential for maintaining durable prints on both light and dark fabrics.

| Topic | Key Points |

|---|---|

| What are DTF transfers | DTF transfers stand for direct to film transfers. The process starts with a digital design printed onto a PET transfer film using a DTF printer with white ink and color inks. The white base helps colors stay vivid on dark fabrics. After printing, an adhesive powder is applied and cured to bond the print to fabric, turning the film into a self-contained transfer sheet. |

| Materials and components | Transfer film, white and color inks, adhesive powder, a heat press, curing equipment, and, in some setups, a carrier sheet to protect the print until application. |

| Understanding the workflow | Workflow stages include: Design and prepress; Printing onto the transfer film; Powder application and curing; Preparing the garment and transfer sheet; The heat press transfer; Peel and finalize; Post press care and durability. |

| Why DTF transfers appeal | Works on a broad range of fabrics, reproduces gradients and fine details, can be cost-effective for small batch runs, requires less setup than some methods, and delivers a soft hand feel with good stretch and durability. |

| Choosing the right setup | A robust DTF printer with reliable white ink, quality transfer film, and consistent curing; proper adhesive powder; a well-tuned heat press; fabric type guiding temperature and time (lighter fabrics may need lower temps; darker fabrics benefit from a strong white base for opacity). |

| Color management and texture | Color management is crucial due to multiple layers and powder. Calibrate with color charts, maintain standard lighting, and anticipate texture variations by fabric type; test on sample fabrics before full production. |

| Durability and care guidance | Durability relies on proper powder curing and adherence. Follow manufacturer heat/time recommendations, avoid aggressive washing early on, pre-treat white areas on dark garments, and perform controlled tests to confirm wash performance. |

| Common mistakes and prevention | Inadequate curing can cause poor adhesion; uneven alignment leads to skewed results; white ink misalignment reduces brightness; overheating can scorch colors; poor edge definition from overfusing or moisture. Prevention includes proper curing, alignment tools, printer calibration, heat control, and dry designs. |

| Maintenance tips for longevity | Keep the DTF system clean and calibrated: clean print heads, monitor ink levels, verify film compatibility, maintain the heat press with even pressure, and store transfer film and powder in cool, dry environments. |

| Practical guidelines for different fabrics | Cotton often yields rich color and strong adhesion; polyesters may need curing adjustments due to heat sensitivity. For blends, test swatches; for dark fabrics, tune the white base for opacity; for light fabrics, rely less on white ink but maintain consistent curing. |

| Fabric-specific notes | Further tailoring your process to each fabric type helps optimize results and durability, including edge handling, ink density, and curing profiles. |

Summary

DTF transfers offer a versatile and efficient method to produce vibrant, durable prints on a wide range of fabrics. This descriptive overview summarizes the end-to-end workflow—from design and prepress to curing, pressing, and care—along with key materials and practical tips. For designers and makers, mastering DTF transfers can shorten production times, reduce waste, and enable scalable workflows across small batches and larger runs.