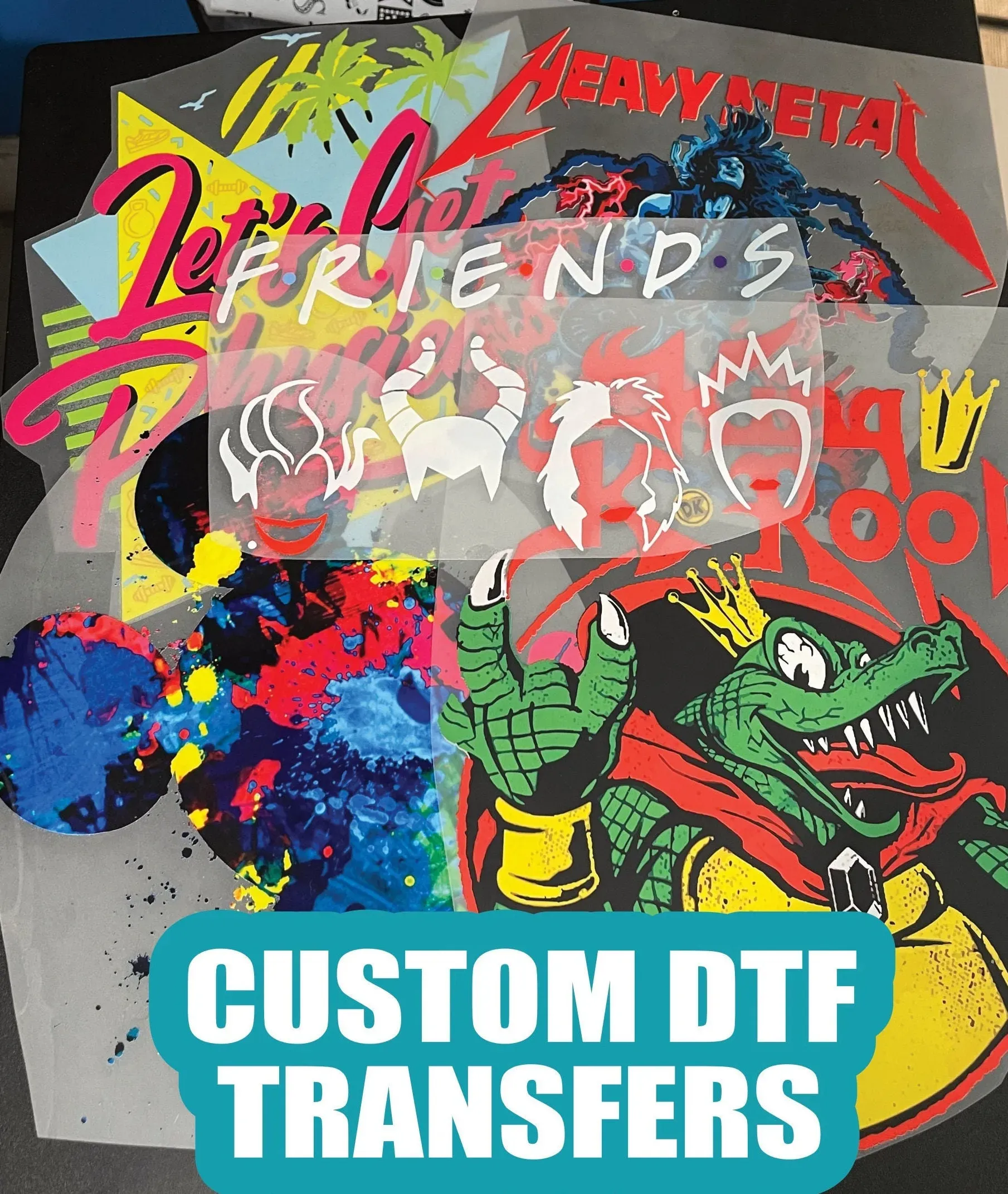

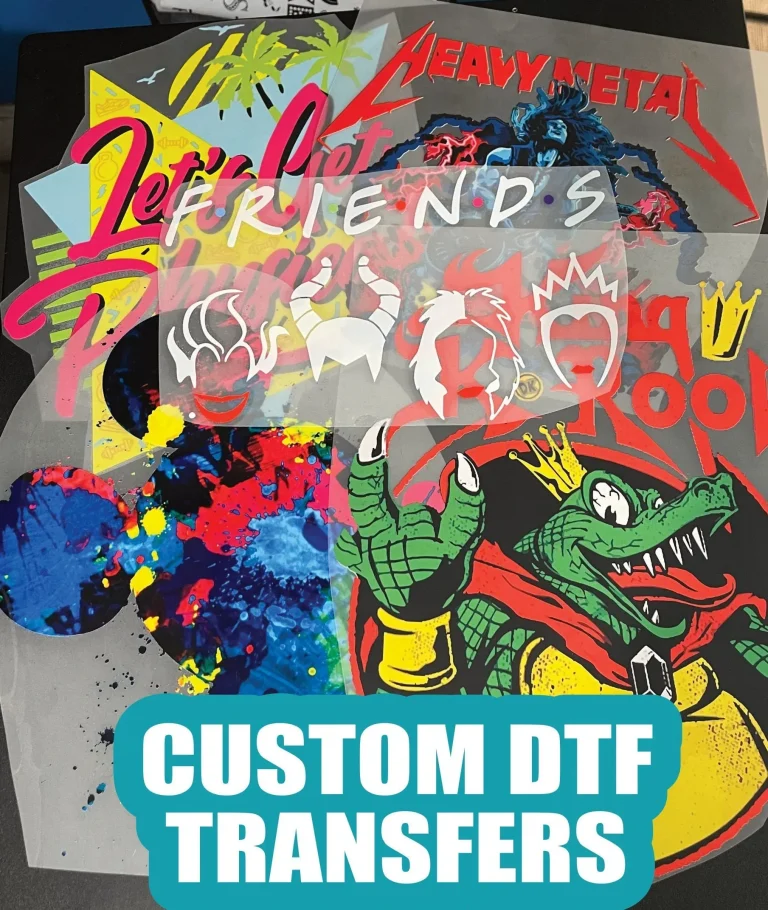

DTF Transfers Explained: Transform Your Printing Process

DTF transfers, or Direct-to-Film transfers, have revolutionized the custom apparel printing landscape by offering unparalleled quality and versatility. This innovative technology enables the creation of vibrant, high-resolution prints that adhere seamlessly to a variety of fabrics. As businesses and entrepreneurs seek more efficient and effective methods for personalized merchandise, DTF printing advantages become increasingly evident. With its user-friendly process and enhanced durability, DTF transfer technology captures the attention of both budding designers and established brands. Embracing sustainable DTF printing solutions, the industry moves towards eco-friendliness while meeting the demands of customization in a fast-paced market.

Exploring the realm of film-based printing, DTF transfers stand out as a premier technique for producing intricate and colorful designs on apparel. Often referred to as Direct-to-Film transfers, this method is gaining traction among businesses looking to keep up with consumer preferences for personalized products. By leveraging advanced printing methods that promise long-lasting quality and efficiency, custom apparel enthusiasts are reaping the benefits of this evolving technology. The process is not only cost-effective but also adaptable to various materials, making it a compelling choice for those aiming to innovate in the merchandising space. As the demand for unique and sustainable printing solutions grows, DTF transfer technology is becoming a cornerstone for modern textile printing.

Understanding DTF Transfers: A Game-Changer in Custom Apparel Printing

Direct-to-Film (DTF) transfers are revolutionizing the world of custom apparel printing by introducing a highly innovative and efficient method of achieving vibrant and intricate designs. This modern technique utilizes a specialized film to transfer designs onto fabric, allowing for a level of detail and color accuracy that is often unmatched by traditional methods. DTF transfers enable businesses to cater effectively to the growing demand for personalized and customized clothing, ultimately transforming the way garments are decorated.

The versatility of DTF transfers extends beyond just apparel; they can be applied to a variety of materials, including textiles and synthetic fabrics, making them ideal for merchandise and promotional products. As a result, more entrepreneurs are adopting this technology to enhance their offerings, facilitating a new wave of creativity and innovation in custom printing solutions. The ability to print on virtually any fabric makes DTF transfers a preferred choice for modern-day merchants looking to stand out in a competitive market.

The Advantages of DTF Transfers: Why They Stand Out

DTF printing presents multiple advantages that set it apart from traditional printing techniques like screen printing and vinyl transfers. First and foremost, the quality of the prints produced through DTF transfers is synonymous with high resolution and vivid colors, making them perfect for creating striking designs that capture attention. Furthermore, this method showcases remarkable durability, as the prints resist fading, cracking, and peeling, maintaining their appeal even after numerous washes.

Another benefit of DTF transfers is their cost-effectiveness. The setup costs are significantly lower compared to screen printing, making this technology an accessible option for small businesses and startups. The ease of use and streamlined process lead to faster production times, enabling businesses to efficiently meet customer demands and adapt quickly to changing trends. As the demand for high-quality, customizable apparel increases, DTF printing stands out as a viable solution for fulfilling these market needs.

Exploring Technological Developments in DTF Printing

The field of DTF printing is constantly evolving, driven by ongoing technological innovations that enhance its capabilities. For instance, advances in ink formulations are paramount in improving flexibility and washability, which in turn increases the longevity and appeal of the final products. This not only attracts businesses but also reassures consumers about the quality and durability of their purchases. As manufacturers continue to refine and develop new ink technologies, the potential for DTF transfers only expands.

Moreover, the introduction of specialized printers tailored for DTF technology marks a significant milestone in accessibility for both seasoned operators and new entrants to the market. Brands like Epson and Mimaki have designed printers that efficiently integrate the DTF process, making it easier for small businesses to produce high-quality prints. This democratization of printing technology opens the door for creative entrepreneurs to explore the possibilities of custom apparel printing without the substantial investment initially required for traditional methods.

Sustainability in DTF Printing: An Eco-Friendly Approach

With growing concerns regarding environmental impacts, sustainability has become a key consideration in the printing industry, including DTF printing. Recent trends show that many ink suppliers are now offering eco-friendly options for DTF transfers, reflecting a broader commitment to reducing the ecological footprint. By incorporating sustainable practices and materials, DTF printing is aligning itself with modern consumer values that prioritize environmentally responsible choices.

This shift towards sustainability is not only beneficial for the planet but also advantageous for businesses looking to attract conscientious consumers. By embracing eco-friendly DTF printing methods, companies can differentiate themselves in a competitive market, appealing to a customer base that increasingly seeks out green products. As innovations continue to emerge in this area, DTF printing has the potential to lead the way in developing sustainable solutions for the entire apparel industry.

Market Trends: The Rapid Growth of DTF Transfers

The adoption of DTF printing is witnessing significant growth, driven by a surge in consumer demand for personalized and high-quality apparel. Recent industry insights highlight that the DTF segment is expected to see substantial advancement due to trends favoring customization and sustainability. This evolving marketplace reflects a shift in consumer preferences, with more individuals gravitating toward unique clothing options that allow for personal expression.

As more businesses invest in DTF technology, the market landscape is transforming, showcasing an increasing variety of printed merchandise from clothing to accessories. The rise of e-commerce and social media has further fueled this growth, as consumers seek out unique and tailored pieces that reflect their personal style. In this dynamic environment, companies leveraging DTF transfers are well-positioned to capitalize on the expanding market for custom apparel, creating ample opportunities for growth and innovation.

Key Takeaways: Embracing DTF Transfers for Future Success

In conclusion, DTF transfers represent a transformative advancement in the printing industry, merging high-quality output with user-friendly operations. The benefits of utilizing DTF technology are numerous, ranging from exceptional detail and durability to affordability and rapid production capabilities. These features make DTF transfers a compelling option for both established businesses and newcomers eager to make their mark in custom apparel.

As consumer demands for customization and sustainability continue to rise, embracing DTF printing technologies positions companies to thrive in an increasingly competitive market. The ongoing evolution of this technology will likely yield further enhancements, making it crucial for businesses to stay informed and adapt to these advancements. Ultimately, the shift towards DTF transfers is not just a trend; it is a necessary step towards a more innovative and sustainable future in custom printing.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, are a modern printing technique where vibrant designs are printed on a special film. This film is then coated with an adhesive powder and applied to various fabrics through heat pressing. This method allows for high-resolution prints that are durable and ideal for custom apparel printing.

What are the main advantages of using DTF transfer technology?

DTF transfer technology offers several advantages, including exceptional print quality with intricate details, durability against washing and wear, cost-effectiveness compared to traditional methods like screen printing, and a rapid production turnaround, making it a favored choice for custom apparel.

How does DTF printing compare to other custom printing methods?

Compared to other methods like screen printing and vinyl transfers, DTF printing stands out due to its ability to achieve higher detail and more vibrant colors. Additionally, DTF transfers are more versatile, working well on a wide range of materials, from cotton to polyester, making them ideal for diverse custom apparel needs.

What recent innovations are enhancing DTF transfer printing?

Recent innovations in DTF transfer printing include improved ink formulations that enhance flexibility and washability, advanced printers designed specifically for DTF applications, and the introduction of eco-friendly inks that reduce the environmental impact, aligning with growing consumer preferences for sustainability.

Are DTF transfers a sustainable option for apparel printing?

Yes, DTF transfers are becoming increasingly sustainable. Many suppliers now offer eco-friendly inks and materials, helping to minimize the ecological footprint of apparel printing. This aligns well with consumer demand for sustainable practices in the fashion industry.

What future trends can we expect in the DTF transfer market?

The DTF transfer market is expected to grow significantly due to rising consumer demands for personalized and high-quality custom apparel. As technology evolves, we can anticipate further advancements in DTF printing equipment and inks, enhancing the overall printing experience and expanding its applications.

| Key Points | Description |

|---|---|

| What Are DTF Transfers? | A cutting-edge printing technique for high-resolution prints applied via heat pressing onto various materials. |

| Key Features | 1. Detailed Prints 2. Versatility of Materials 3. Streamlined Process |

| Advantages | 1. High Quality 2. Durability 3. Cost-Effectiveness 4. Rapid Turnaround |

| Recent Developments | 1. Improved Ink Formulations 2. Innovative Equipment 3. Eco-Friendly Options |

| Market Trends | Growing demand for personalized apparel has led to rapid adoption of DTF transfers in the market. |

| Key Takeaways | 1. Superior quality and detail 2. Sustainable practices 3. Anticipated growth in demand |

Summary

DTF transfers are revolutionizing the printing landscape by offering a unique solution that combines quality, efficiency, and versatility. As industries transition towards more customized and sustainable practices, DTF transfers are becoming increasingly essential. Their ability to produce vibrant, high-resolution prints makes them an ideal choice for businesses aiming to meet consumer demands for personalized apparel. With ongoing advancements in technology and an increasing focus on eco-friendly practices, DTF transfers stand as a key player in the future of printing. Companies looking to enhance their printing capabilities would be wise to consider integrating DTF transfers into their operations.