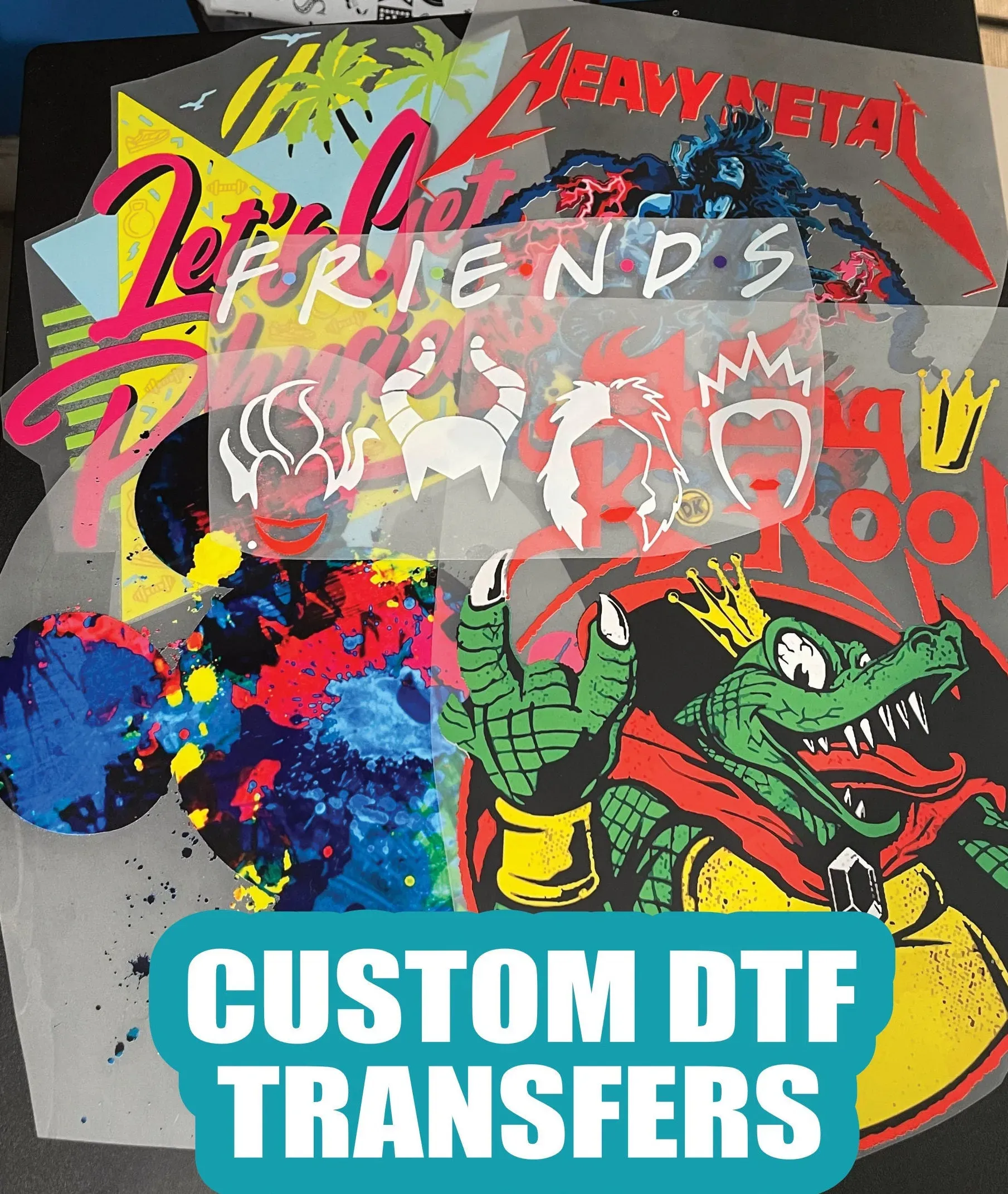

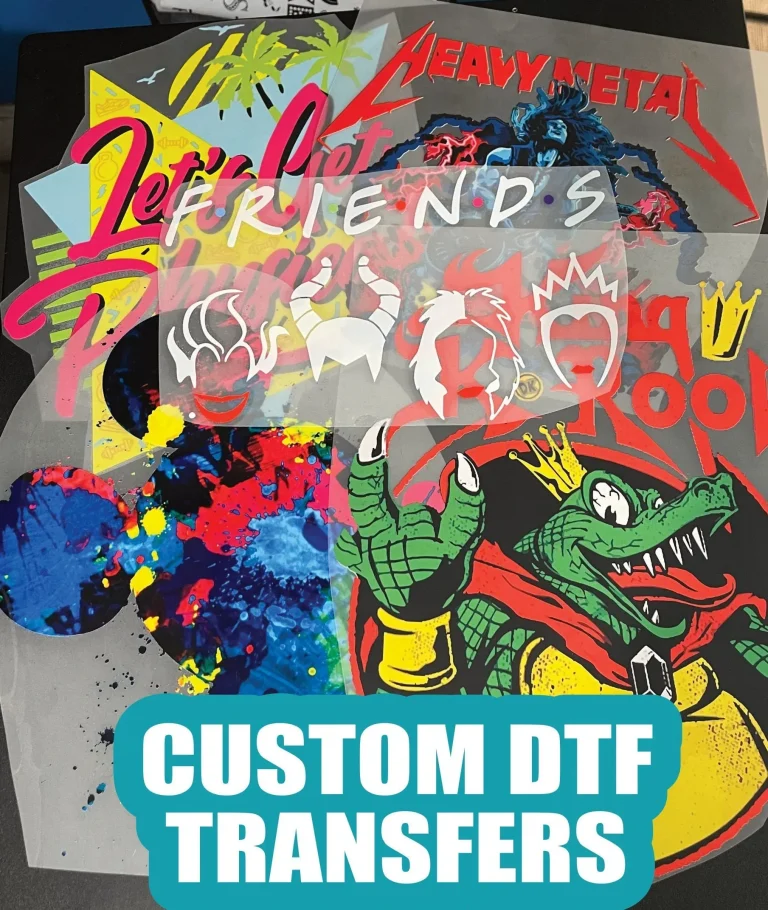

DTF Transfers: Comparing Printing Methods for Your Needs

DTF transfers, or Direct-to-Film printing, have rapidly emerged as a groundbreaking solution in the realm of custom transfer printing, revolutionizing how designs are applied to fabric. This innovative technique stands apart from traditional methods such as sublimation printing and screen printing, offering creators a versatile means to produce high-quality images on a variety of materials, including cotton and polyester blends. With vibrant colors and intricate designs achievable through DTF, users are empowered to push the boundaries of creativity while ensuring durability and longevity in their prints. In this article, we will delve deeper into the benefits of DTF transfers, comparing them against other popular printing methods and helping you identify which one suits your unique requirements best. Join us as we explore the expanding landscape of DTF printing and uncover the potential it presents for businesses and crafters alike.

Direct-to-Film technology, commonly referred to as DTF printing, is transforming the way we think about custom printing solutions. With its ability to transfer high-resolution images onto a wide array of fabrics, DTF stands out when compared to conventional processes such as traditional screen printing and sublimation methods. This sophisticated printing approach not only brings designs to life with rich, vibrant colors but also allows for greater flexibility when it comes to material choices. In this discussion, we will examine the core advantages offered by DTF technology, taking a closer look at how it addresses various printing challenges while providing users with an exceptional experience. Ultimately, understanding these nuances will guide you toward making an informed decision on the best printing method for your needs.

Understanding DTF Transfers in the Printing World

Direct-to-Film (DTF) transfers represent a significant innovation in the printing industry, merging technology with creativity. Unlike traditional methods such as screen printing and sublimation, DTF printing allows for color-rich, high-quality images to be transferred onto a variety of materials, including cotton and polyester blends. This versatility makes DTF a preferred choice for businesses looking to print custom designs on apparel or textiles. It caters not only to large production houses but also to smaller enterprises and hobbyists, establishing its place as a reliable option for custom transfer printing.

By using a specialized film, DTF printing creates a higher quality design that can withstand the rigors of wear and washing. This technique involves applying adhesive to the printed film before heat-pressing it onto the desired fabric. As a result, the vibrant colors and intricate details remain intact long after multiple washes, making it an excellent alternative to both screen printing and sublimation methods. Understanding the mechanics behind DTF transfers can help business owners and creators make informed decisions about which printing method aligns best with their operational needs.

The Advantages of DTF Transfers Over Other Methods

DTF transfers offer a myriad of benefits that set it apart from other printing methods such as sublimation and screen printing. One of the most significant advantages is its fabric compatibility. While sublimation printing is limited to polyester fabrics, DTF enables a broader spectrum of printing options, including cotton and blends. This diversity opens up new horizons for creativity in custom design and product offerings, allowing businesses to cater to various customer preferences and market demands.

Additionally, DTF printing boasts high color vibrancy and detail. The precision involved in the printing process allows for intricate designs and sharp images that capture attention. This is particularly beneficial for apparel businesses wanting their products to stand out. While sublimation also provides excellent vibrancy, the unique layering technique of DTF ensures durability and resistance to fading over time—even after several washes. Consequently, brands that invest in DTF transfers can deliver products that maintain their quality, further enhancing customer satisfaction.

DTF Printing Cost-Effectiveness Compared to Screen Printing

When evaluating the cost-effectiveness of DTF transfers versus screen printing, several factors come into play. Screen printing requires significant upfront investment, including screens, inks, and setup costs, which can be overwhelming for small businesses or independent creators. In contrast, DTF printing simplifies this process with a lower barrier to entry. Recent advances in DTF technology have resulted in more affordable printers and materials, making it easier for newcomers to enter the market without a financial strain.

Moreover, DTF printing allows for smaller batch sizes without incurring additional costs typically associated with screen printing. This flexibility means that companies can produce custom, one-off designs at a competitive price point, appealing to trends that favor personalized products. As businesses navigate a landscape that increasingly favors uniqueness and custom offerings, DTF transfers provide an economically savvy solution that does not compromise on quality.

The User-Friendly Nature of DTF Transfers

One of the standout features of DTF transfers is their user-friendly nature, which is advantageous for both printing veterans and newcomers alike. The DTF printing process is relatively straightforward compared to the complexities of screen printing, which involves intricate setup and process handling. Users can quickly become proficient in operating DTF printers, significantly reducing the learning curve associated with traditional printing methods.

This ease of use translates into quicker turnaround times for customer orders and enhances overall productivity for small businesses. Given the rapidly changing demands of the printing market, being able to pivot and respond to orders swiftly is crucial. Embracing DTF printing technology not only streamlines operational processes, but also provides creators and entrepreneurs with a reliable method to bring their designs to life efficiently.

Advancements in DTF Printing Technology

Recent advancements in DTF printing technology have further propelled its standing in the printing industry. Companies are continuously innovating to enhance the performance and capabilities of DTF printers. For instance, the introduction of large-format printers expands the production capacity for high-volume orders, allowing businesses to scale their operations while maintaining quality. This trend underscores the growing demand for DTF as a preferred choice for custom garment printing.

Additionally, user-friendly online platforms for DTF printing have emerged, facilitating easier access for businesses. These platforms enable users to manage their print orders from virtually anywhere, ensuring a streamlined experience for both crafters and commercial enterprises. With such advancements, DTF printing not only keeps pace with consumer expectations but also positions itself as a frontrunner in the dynamic world of print technology.

Comparative Analysis: DTF, Sublimation, and Screen Printing

Conducting a comparative analysis of DTF printing against sublimation and screen printing reveals distinct strengths and weaknesses inherent to each method. DTF printing shines with its flexibility in fabric compatibility and design capabilities, allowing users to print on multiple fabric types while achieving vibrant color reproduction that aligns closely with custom needs. In comparison, sublimation is limited to polyester fabrics and may not offer the same degree of design versatility when fabric variety is essential.

On the other hand, screen printing excels with high-volume production, providing cost benefits for bulk orders after initial setup costs are covered. However, unlike DTF, it struggles with intricate designs, often requiring multiple screens for different colors, which can complicate the printing process. By understanding these comparative aspects, businesses can better determine their strategic approach to selecting the most suitable printing method for their specific requirements.

Frequently Asked Questions

What are the benefits of using DTF transfers over sublimation printing?

DTF transfers offer greater versatility as they can be used on a wider range of fabrics, including cotton and blends, unlike sublimation which works best on polyester. DTF printing also produces vibrant colors and high-resolution images, making it a preferred option for intricate designs. Additionally, DTF has lower start-up costs compared to sublimation, making it more accessible for small businesses.

How does DTF printing compare to screen printing?

When comparing DTF printing to screen printing, DTF is more beginner-friendly with less complex setup and lower initial investment costs. While screen printing is ideal for large bulk orders, DTF works well for small to medium runs, especially custom orders. DTF also allows for multi-color designs in a single setup, streamlining the printing process compared to the multiple screens required in screen printing.

Can DTF transfers be used on all types of fabrics?

DTF transfers are highly versatile and can be applied to a variety of fabrics, including cotton, polyester, and blends. This versatility gives creators more options for customizing clothing and merchandise compared to other methods like sublimation, which is limited to polyester fabrics.

What makes DTF printing a scalable option for businesses?

DTF printing is becoming a scalable option for businesses due to its user-friendly platforms and recent advancements in technology that have reduced equipment costs. This makes DTF accessible to both large and small businesses, allowing them to meet varying customer demands efficiently, even for custom transfers.

Is the color quality of DTF transfers comparable to sublimation and screen printing?

Yes, DTF transfers provide excellent color vibrancy and detail, comparable to sublimation and often superior to screen printing when it comes to intricate designs. DTF prints are UV resistant and durable, ensuring that vibrant colors and high-quality images stand the test of time, even after multiple washes.

What are the key advantages of custom transfer printing with DTF technology?

Custom transfer printing using DTF technology offers advantages such as flexibility in fabric choices, cost-effectiveness with lower start-up costs, and the ability to produce vibrant, high-quality designs quickly. Furthermore, the recent launch of custom services for DTF printing enhances the accessibility for crafters and small businesses, making it easier to tap into the custom print market.

| Key Points | Description |

|---|---|

| What is DTF Printing? | A technique that prints designs onto a special film for transfer onto various materials. |

| Recent Developments | Custom services and production capacity enhancements make DTF more accessible. |

| Versatility with Fabrics | Compatible with cotton, blends, and some synthetics, offering more options. |

| Color and Design Quality | Produces vibrant colors and high-resolution images, durable after washes. |

| Ease of Use | Simpler process compared to traditional printing methods. |

| Lower Start-Up Costs | Lower barrier to entry than methods like screen printing. |

Summary

DTF transfers are establishing themselves as a significant method in the printing industry, thanks to their unique advantages over traditional techniques. The vibrant colors, ease of use, and compatibility with various fabrics make DTF printing an appealing option for creators and businesses alike. By embracing DTF transfers, crafters can simplify their processes and reduce expenses while still producing high-quality designs. The ongoing developments in DTF technology indicate that its popularity will continue to grow, making it essential for potential users to consider this innovative method as a viable choice for their printing needs.