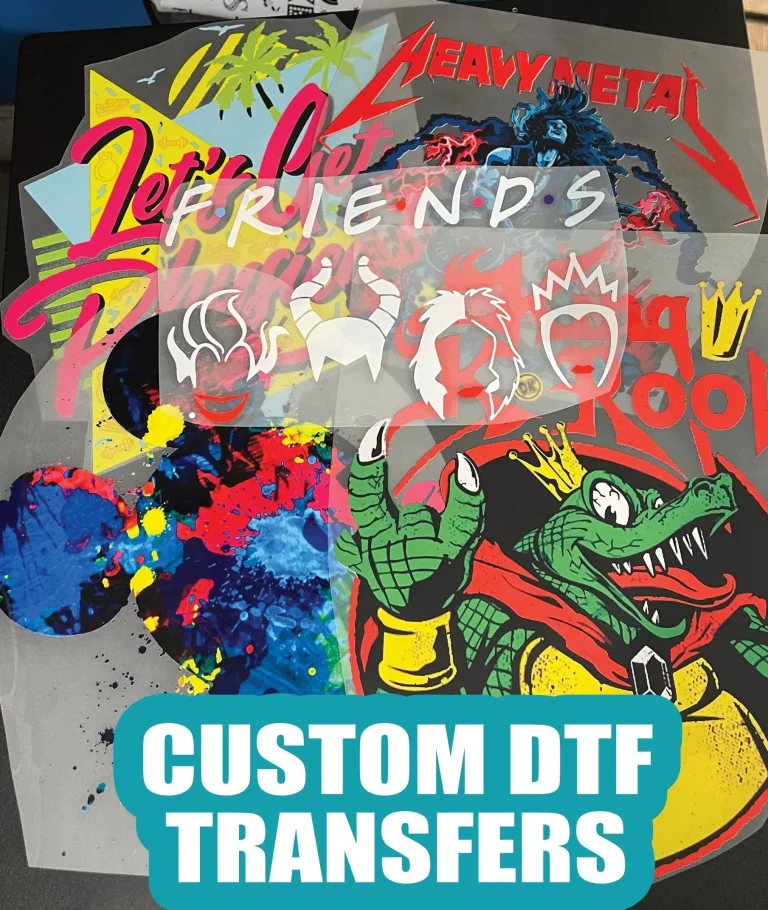

DTF Transfers: Color Vibrancy and Durability Explained

DTF transfers, or Direct-to-Film transfers, are revolutionizing the textile printing landscape with their exceptional ability to deliver vivid colors and remarkable durability. This innovative printing technology utilizes a unique process where designs are printed onto a special film and then transferred onto fabrics, making it an enticing choice for businesses and individuals alike. Known for the intense color vibrancy in printing, DTF transfers provide stunning visuals that stand out in any application, from clothing to promotional materials. Furthermore, the durability of DTF prints ensures longevity, resisting fading and wear, which is crucial in today’s fast-paced consumer market. As we explore the various DTF transfer applications, it becomes evident that this technology is not just a trend, but a reliable method poised to define the future of custom printing.

Direct-to-Film (DTF) printing technology is a game changer in the world of fabric decoration, offering an alternative to traditional methods like screen printing and heat transfer vinyl. This advanced printing technique allows for intricate designs featuring a wide spectrum of colors, deploying high-quality inks that enhance both the aesthetic appeal and durability factor of the prints. DTF transfer methods make it possible to create personalized merchandise, catering to the rising demand for unique and custom items in retail. The infusion of color vibrancy and robust print life adds great value, making it a preferred choice among entrepreneurs and small businesses looking to make their mark. As interest in this versatile printing approach grows, its adaptability continues to capture the imagination of designers and consumers alike.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology represents a substantial leap in textile printing methods. This innovative process involves printing designs onto a specialized film that is later transferred to fabric through heat. Utilizing water-based and plastisol inks, the DTF process is engineered to deliver a robust color gamut, allowing for highly detailed and vibrant prints. Unlike traditional methods such as screen printing, DTF facilitates more intricate designs without sacrificing quality or efficiency, making it a favorite among both small businesses and larger manufacturing entities.

The nuances of DTF printing technology also extend beyond color delivery. The method supports a variety of substrates, enhancing its appeal across different sectors. Our current era witnesses an increasing trend among decorators and entrepreneurs gravitating toward DTF for its versatility, accommodating everything from cotton and blends to unique fabric types while maintaining performance integrity. This adaptability contributes positively to its growing popularity in niche markets, such as custom clothing and personalized merchandise.

Color Vibrancy: The Key Advantage of DTF Transfers

One of the most commendable aspects of DTF transfers is their impressive color vibrancy. DTF printing leverages advanced ink formulations that promise deeper shades and lighter hues, resulting in an extensive palette for creative expression. High-quality inks utilized in the process not only amplify color vibrancy but also sharpen the clarity of minute details, leading to more striking visual outcomes. Artists and designers have the freedom to experiment with colors and designs without the fear of losing quality, establishing DTF as an essential tool for fresh and captivating fabric designs.

Moreover, the correlation between color vibrancy and fabric choice isn’t to be overlooked. While DTF prints shine on a variety of materials, they particularly excel on cotton and cotton blends, where colors appear rich and saturated. This compatibility ensures that recipients of printed items experience the full effusions of artistry, favorably impacting customer satisfaction and repeat business. Thus, the combination of high-quality ink and optimal fabric makes DTF transfers a prime choice for those pursuing dynamic and visually appealing merchandise.

Durability of DTF Prints: What You Need to Know

Durability stands as a hallmark of DTF prints, setting the technology apart from traditional printing methods. Whether it’s for uniforms, sports gear, or fashion items, the ability of DTF prints to withstand aspects such as washing and wear without significant degradation is impressive. The proprietary adhesive powder used in DTF printing plays a crucial role, binding the ink to fabric and ensuring that designs resist fading, cracking, or peeling over time. This reliability captures the interest of businesses, especially those in highly competitive industries where quality can define longevity.

Further enhancing the durability are the post-processing methods employed during the DTF transfer application. Adjustments in time and temperature based on fabric type can dramatically affect print lifespan. Properly executed procedures ensure that the vibrant colors of DTF prints not only last through countless washes but also maintain their vividness, ultimately translating to greater customer satisfaction. The robust nature of DTF prints places them as a superior choice for high-performance applications, making them increasingly favored across various markets.

The Transformative Applications of DTF Printing

DTF printing has rapidly found its place in multiple realms like clothing, accessories, and personalized merchandise, showcasing its transformative potential. As consumers seek unique and custom options, the versatility of DTF transfers allows businesses to respond to these evolving needs effectively. From vibrant T-shirts to custom tote bags, the technology enables businesses to create products that resonate with individual preferences while ensuring quality and durability.

Moreover, as small businesses and startups strive to carve out their niches in the market, DTF printing provides an efficient path for custom creations without the economic burden often associated with traditional methods. This convenience encourages a wave of creativity and experimentation, leading to products that stand out in a saturated market. The ability to produce small batches while maintaining consistent quality gives businesses an advantage, helping them thrive amidst varying demand.

Current Trends in the DTF Transfer Market

With rapid advancements in DTF transfer technology, the market is witnessing an unprecedented surge in innovation and adoption. New manufacturers are entering the arena, offering state-of-the-art printers and transfer films designed to enhance application diversity. This influx of talent and technology ensures that businesses can stay ahead of the curve without compromising quality. Retail adoption is on the rise, attributing to DTF’s scalability, allowing retailers to cater to both large and small orders seamlessly.

As competition escalates, the emphasis on cost-effectiveness becomes fundamental. Companies across the spectrum are recognizing the benefits of DTF technology, particularly its ability to simplify the production process while delivering exceptional results. This trend encourages retailers to capitalize on DTF’s advantages, bolstering a rapidly expanding ecosystem where both experienced manufacturers and enthusiastic newcomers can flourish.

Environmental Considerations for DTF Printing

As sustainability gains traction within the textile industry, considerations surrounding environmental impact become paramount. DTF printing is gradually shifting towards more environmentally friendly practices, with several manufacturers investing in the development of biodegradable ink formulations. These innovations not only address ecological concerns but also align with contemporary consumer preferences for sustainable products. Businesses adopting these methods will not only fulfill corporate social responsibility goals but will also attract environmentally conscious consumers.

In addition to ink sustainability, evaluating substrate compatibility and chemical use within the DTF process plays an essential role. Transitioning towards environmentally responsible materials ensures that the printing process maintains efficacy while reducing environmental footprints. As technologies advance and consumers grow increasingly aware of the ecological implications of their purchases, DTF’s commitment to sustainability can serve as a valuable differentiator in a crowded market.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special PET film using high-quality inks. The printed film is then heat pressed onto fabric, resulting in vibrant, durable prints. This technology is favored for its ability to deliver detailed graphics with excellent color vibrancy on various fabrics.

How does color vibrancy in DTF printing compare to other printing methods?

Color vibrancy in DTF printing is significantly enhanced by the use of top-grade, water-based inks that provide a wide color gamut. This surpasses many traditional methods, yielding prints with stunning colors and intricate details that stand out on garments, making DTF a popular choice for businesses seeking impressive visual impact.

What ensures the durability of DTF prints against fading and wear?

The durability of DTF prints relies on several factors, including the use of high-quality adhesive powder that binds inks to fabrics, ensuring long-lasting adhesion. Correct heat press techniques also play a role; when applied properly, they prevent fading, cracking, and peeling, contributing to the overall longevity of the transfers.

Can DTF printing be used on all fabric types?

While DTF printing offers versatility on many fabrics, it performs best on cotton and cotton blends. Users should note that it may not achieve optimal results on 100% polyester fabrics, where sublimation printing tends to excel. Understanding substrate compatibility is crucial for achieving desired printing outcomes with DTF transfers.

What are the main applications of DTF printing technology?

DTF printing technology is applicable across various sectors, including custom apparel, merchandise, and promotional products. Its adaptability makes it ideal for both bulk orders and one-off custom designs, providing businesses with the flexibility to cater to diverse customer needs without sacrificing quality.

How does DTF printing address sustainability concerns in the textile industry?

The DTF printing process is evolving toward sustainability, with recent innovations focusing on more biodegradable ink formulas. This development is essential for businesses aiming to adopt environmentally friendly practices, as it reduces the ecological footprint associated with traditional printing methods while maintaining high-quality output.

| Key Feature | Description |

|---|---|

| What Are DTF Transfers? | Involves printing a design onto special film, then heat transferring onto fabric, allowing for vibrant, long-lasting prints. |

| Color Vibrancy | High-quality, water-based inks provide broad color gamut and excellent detail clarity in designs. |

| Durability | Resistant to fading, cracking, and peeling; relies on high-quality adhesive powder and careful post-processing. |

| Market Trends | Rapid growth of DTF technology and adoption by small businesses due to its cost-effectiveness and scalability. |

| Considerations | Users must consider substrate compatibility and sustainability factors for successful DTF printing. |

| Future Innovations | Ongoing improvements aim to enhance adhesion, longevity, and sustainability in DTF printing practices. |

Summary

DTF transfers are revolutionizing the textile printing industry with their vibrant colors and exceptional durability. Businesses leveraging DTF printing can produce high-quality products tailored to the diverse market demands while enjoying ease of use and cost-effectiveness. This technology has opened new avenues for creativity, allowing companies to offer detailed and customizable merchandise. As the market evolves, innovations focused on sustainability and efficiency will further enhance the capabilities and popularity of DTF transfers, ensuring they remain at the forefront of fabric printing.