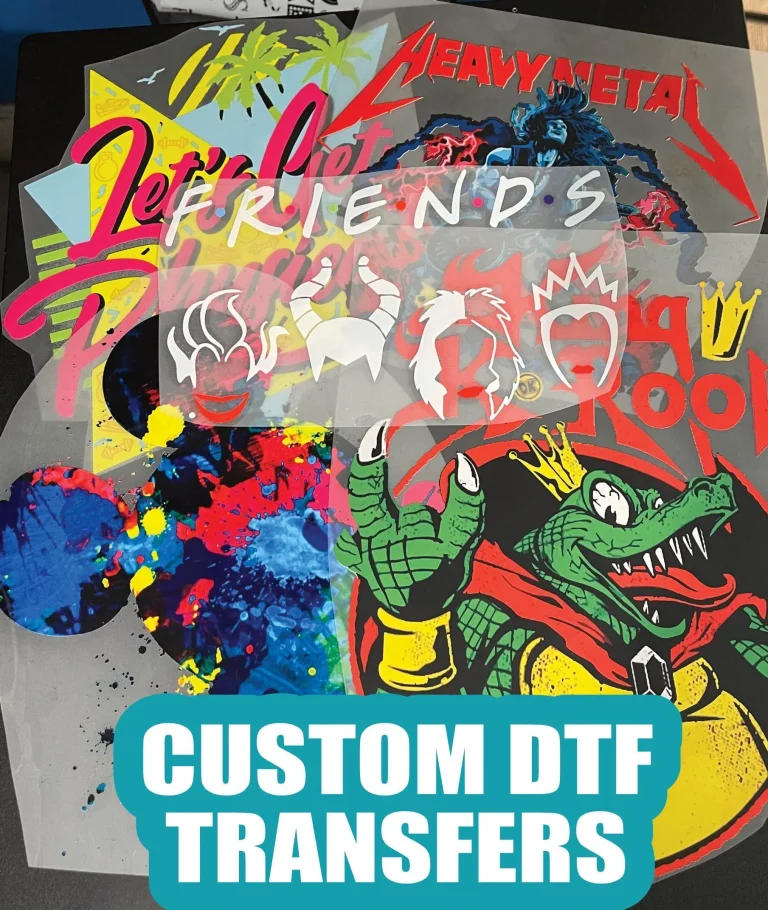

DTF Transfers: Achieve Consistent Results Every Time

DTF transfers are reshaping how creators decorate garments, delivering durable, vivid results for small businesses and hobbyists alike. To achieve consistency, you need the right mix of supplies, careful prep, and a reliable transfer workflow that minimizes variables. In this guide, you’ll find practical steps and tips aligned with DTF printing tips to help you reach uniform, high-quality DTF transfers across cotton, blends, and poly fabrics. From choosing DTF supplies for beginners to dialing in heat press settings, the process is presented as a coherent system, not a series of one-off attempts. By following the steps and recording what works, you can improve DTF transfer consistency and deliver reliable results batch after batch.

In other words, this film-based garment decoration method uses a printed design on a specialized sheet that is sandwiched with adhesive powder and fused to fabric with heat. Think of it as a modern print-on-film technique that applies a design to textiles via heat and a powdered adhesive. The approach emphasizes DTF film quality, substrate compatibility, and precise heat press settings to ensure durable, color-rich results. By framing the topic with alternative terms such as direct-to-film printing and adhesive-powder transfer, you align with search intent while preserving clarity for readers. Understanding these terms helps new users feel confident as they explore equipment and supplies for beginners.

DTF Transfers: Achieving Consistency with the Right Supplies and Workflow

DTF transfers are most predictable when you start with reliable, compatible components and a well-defined workflow. The quality of your supplies—DTF film quality, compatible inks, and uniform adhesive powder—sets the baseline for color accuracy and adhesion, while a careful, repeatable process helps minimize variables from file to file. By focusing on DTF transfer consistency and adopting printing tips that emphasize color management, calibration, and controlled post-print handling, you lay the groundwork for uniform results across cotton, blends, and synthetics.

To support beginners, build a core set of dependable DTF supplies and document your process. Create standardized work instructions that cover artwork checks, film and powder handling, and post-press steps, then expand as you gain experience with different fabrics. When you couple reliable supplies with a repeatable workflow, you’ll find that DTF supplies for beginners become a stepping stone to consistent, professional-quality transfers rather than a source of trial-and-error frustration.

DTF Film Quality and Heat Press Settings: A Practical Guide to Reliable Prints

The journey to reliable DTF prints starts with the film itself. DTF film quality directly influences how inks lay down, how evenly the adhesive transfers, and how cleanly the print releases at the end. A smooth, defect-free film minimizes color shifts and banding, helping you maintain consistency across batches. Coupled with proper powder application and curing practices, a high-quality film foundation supports durable, vibrant transfers on cotton, blends, and polyester.

Equally critical are the DTF heat press settings—temperature, time, and pressure must be tuned to the fabric and adhesive formulation you’re using. Start with a baseline (for example, around 180-200°C for 15-30 seconds with even, moderate pressure) and adjust based on fabric type, color density, and results from test swatches. Document these adjustments and perform regular calibration checks to ensure repeatability. By focusing on DTF film quality and precise DTF heat press settings, you’ll improve transfer consistency and achieve reliable, high-quality results with every batch.

Frequently Asked Questions

What are essential DTF printing tips to improve DTF transfer consistency across batches?

Start with a solid lineup of DTF supplies and a repeatable workflow. Prioritize DTF film quality and reliable inks, maintain color management with ICC profiles, run test prints, and fine-tune DTF heat press settings for each fabric. Document results to reproduce uniform DTF transfers on cotton, blends, or polyester.

How do you choose DTF supplies for beginners to ensure reliable DTF transfers and transfer consistency?

Begin with a core set of DTF supplies for beginners: high-quality DTF film quality, compatible inks, uniform adhesive powder, and fabric-friendly substrates. Check film quality, use recommended heat press settings, and run small trials to calibrate. This approach supports DTF transfer consistency and better outcomes across fabrics.

| Section | Key Points |

|---|---|

| Overview | DTF transfers are changing how small businesses and hobbyists approach custom garments. Success depends on the right combination of supplies, careful preparation, and a reliable transfer workflow. |

| Understanding DTF Transfers | Process: print on specialized film with pigment inks, apply adhesive powder, and transfer with heat/pressure. Enables vibrant color on many fabrics; consistency hinges on supplies, color management, heat settings, and post-print handling. |

| Choosing the Right DTF Supplies | Key components: DTF film quality, inks/printers, adhesive powder, substrate compatibility, and support tools. Invest in dependable supplies for repeatability and start with a core set. |

| Setting Up for Consistent Prints | Calibrate color management with ICC profiles; plan designs with bleed and margins; use high-resolution artwork (300 dpi or higher); run test prints; maintain printer health for reliable results. |

| From Film Quality to Powder Application | Film quality affects ink laydown; uniform powder application ensures even adhesion; cure/condition as needed; store film in a cool, dry environment to avoid moisture-related issues. |

| The Transfer Process: Heat, Time, and Pressure | Typical starting settings: 180-200°C (356-392°F); 15-30 seconds dwell; apply even, moderate pressure; use protective sheets; allow cooldown before removing carrier. |

| Achieving DTF Transfer Consistency Across Batches | Create standardized work instructions; maintain a transfer log (film, ink, powder, temp, time, pressure, substrate); perform regular calibration checks; use test swatches; optimize substrate preparation. |

| Troubleshooting Common Issues | Symptoms and fixes include color shifts (adjust color management), ghosting (check curing/ alignment), peeling (verify substrate compatibility and cooling), cracking (adjust heat/time), uneven brightness (inspect film and printer head). |

| Maintenance and Storage of DTF Supplies | Store films upright; seal inks and powders; clean printers and heat presses; replace worn components; label batches with date and lot numbers for traceability. |

| Substrates and Aesthetic Considerations | Cotton and blends yield vibrant colors with proper settings; polyester may require adjustments; dark fabrics often need a white underbase; testing on samples is advisable. |

Summary

Conclusion: A concise, actionable process for DTF transfers