DTF transfers 101: Beginner’s Guide to Fabric Printing

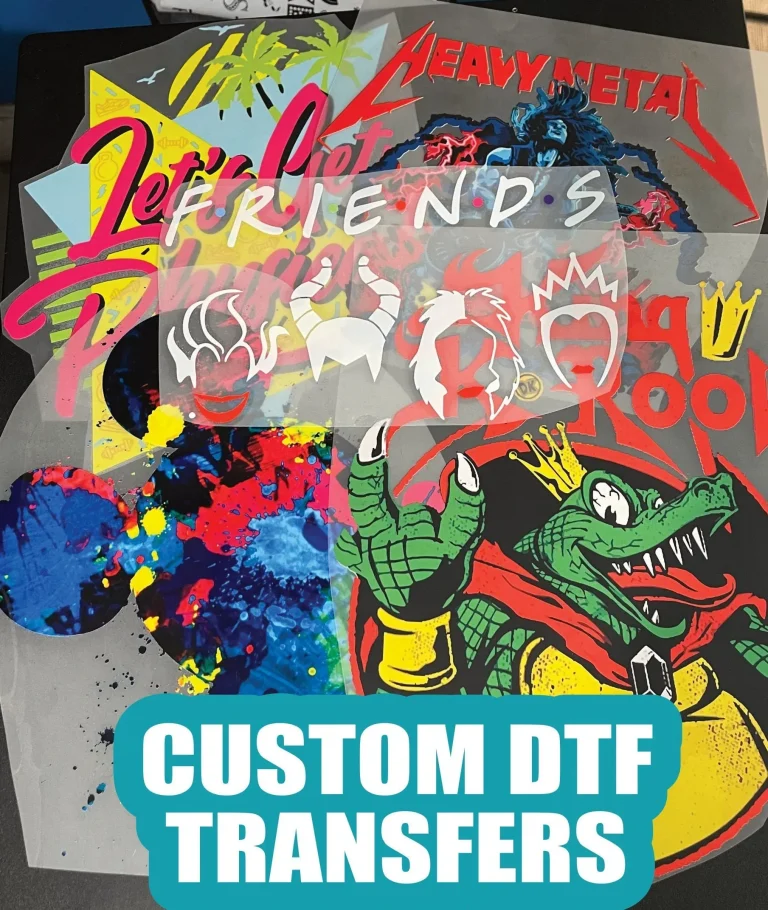

DTF transfers have quickly become a popular option for hobbyists and small businesses looking to print high-quality designs on fabric. This method, short for direct-to-fabric transfers, combines inkjet printing with heat-press technology to deliver vibrant, durable results on a wide range of textiles and is a key part of the DTF printing process. If you’re new to fabric printing, understanding the direct-to-fabric printing process can unlock design possibilities without bottlenecks. DTF transfer applications span T-shirts, hoodies, tote bags, and home textiles, offering versatility for custom shops and makers. Compared with DTG and traditional screen printing, DTF vs screen printing highlights a balance of setup simplicity, color richness, and fabric compatibility.

From a different angle, this fabric-transfer technology can be described as heat-transfer printing for textiles, emphasizing on-demand customization and strong color fidelity. The process relies on a printable PET film, an adhesive powder, and a heat press to fuse artwork onto cotton, polyester blends, and more. In the broader fabric printing ecosystem, this approach is known as garment transfer printing, transfer-on-textile workflows, or dye-transfer style methods that share the same core steps. Understanding these alternative terms helps designers and buyers align expectations around opacity, durability, and care when comparing DTF printing options to other methods.

DTF transfers and direct-to-fabric printing: essential guide for beginners

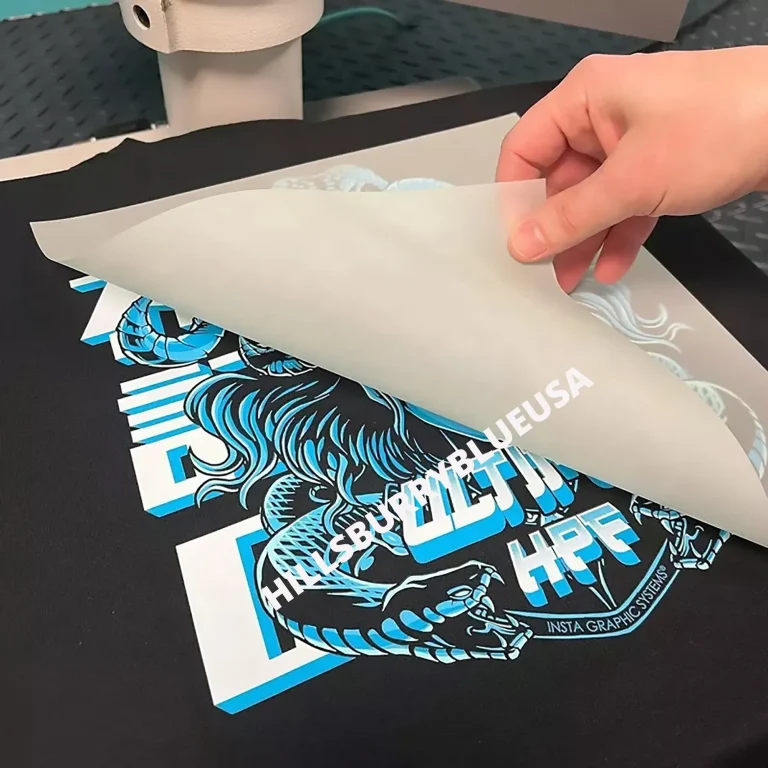

DTF transfers and direct-to-fabric printing offer a beginner-friendly path to vibrant, durable designs on a wide range of textiles. In a typical DTF workflow, a design is printed onto a PET film with a white underbase to improve opacity on dark fabrics. After printing, hot-melt adhesive powder is applied and cured, and the finished film is heat-pressed onto the garment to fuse the image into the fabric.

Compared with other methods, DTF transfers provide a practical middle ground between direct-to-garment (DTG) printing and traditional screen printing. DTF vs screen printing: for small- to medium-sized runs you can achieve rich color and detail with less upfront setup, and it works on many fabric types beyond cotton. The DTF printing process is also compatible with a variety of printers, films, and powders, making it accessible to hobbyists as well as small businesses.

DTF transfer applications and the practical workflow: from design to fabric

DTF transfer applications span T-shirts, hoodies, tote bags, athletic wear, and even home textiles, illustrating the versatility of direct-to-fabric printing. The DTF printing process typically starts with artwork preparation and color management, followed by printing onto the PET film and applying a white underbase if needed. After the powder adhesive is added and cured, the film is placed on fabric and bonded with heat and pressure to create a durable transfer.

For beginners, developing a practical workflow means focusing on testing and standardization. Start with simple designs, test on several fabric types, and document printer profiles, film choices, powder types, and heat-press settings so you can reproduce successful results. By exploring DTF transfer applications across different fabrics and orders, you’ll learn which combinations of materials and parameters deliver consistent color, opacity, and adhesion for your specific garments.

Frequently Asked Questions

What is the DTF printing process and what are common DTF transfer applications?

DTF transfers are created through the DTF printing process: the design is printed onto a PET film (often with a white underbase for opacity), a hot-melt adhesive powder is applied and cured, and the film is then bonded to fabric with heat and pressure. In direct-to-fabric printing workflows, common DTF transfer applications include T-shirts, hoodies, tote bags, athletic wear, and soft goods, across cotton, polyester blends, and other fabrics.

How does the DTF vs screen printing comparison affect decision-making for small runs and dark fabrics?

DTF transfers offer easier setup and strong color on many fabrics for small-to-medium runs, thanks to the DTF printing process, including good opacity with a white underbase. Screen printing, while cheaper for large volumes, requires screens and more setup. For direct-to-fabric printing, choosing DTF transfer applications can enable faster turnaround and on-demand printing for diverse fabric types.

| Topic | Key Points |

|---|---|

| Definition |

|

| Direct-to-Fabric printing process |

|

| DTF vs other methods |

|

| Equipment and materials |

|

| Design considerations and color management |

|

| Applications and use cases |

|

| Troubleshooting and optimization |

|

| Cost, maintenance, and ROI considerations |

|

| Best practices for beginners |

|

Summary

DTF transfers offer a versatile, beginner-friendly path into the world of direct-to-fabric printing. By understanding the fundamental steps of the DTF printing process, selecting the right materials and equipment, and paying attention to color management and testing, you can achieve vibrant, durable results across a wide range of fabrics. Whether you’re printing for a small business, custom orders, or personal projects, the combination of high-quality prints, manageable setup, and flexible application makes DTF transfers a compelling option. As you gain experience with direct-to-fabric printing, you’ll discover how to optimize each stage—from artwork preparation and printing to powder curing and bonding—so your designs come to life on fabric with precision and consistency. Remember, success in DTF transfers comes from thoughtful planning, careful testing, and steady practice with the DTF transfer process. Embrace the potential of direct-to-fabric printing, and you’ll be well on your way to delivering standout garments and products that attract attention and drive growth.