DTF Transfer Tips: Master Your Printing Game Today

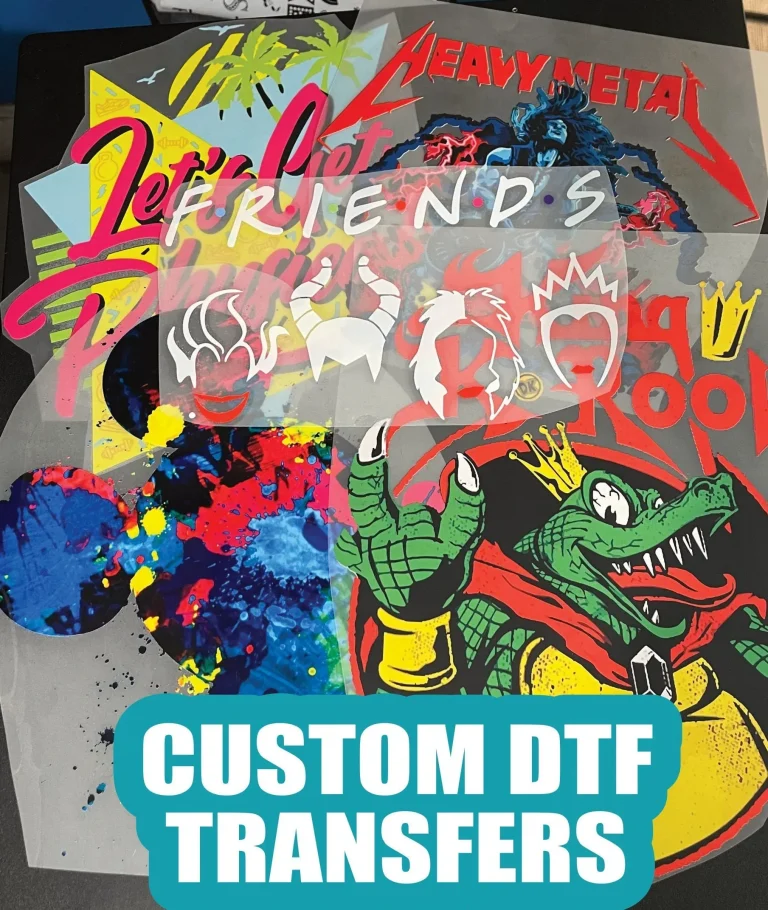

If you’re looking to improve your printing projects, understanding **DTF transfer tips** can be your stepping stone to success. Direct-to-Film printing, an innovative technique, is becoming increasingly popular due to its ability to deliver stunning visuals on various fabrics. For beginners, mastering the fundamentals of DTF printing is essential to achieving professional-quality results. Whether you’re interested in print quality or learning the best DTF printing techniques, the right tips can greatly enhance your skills. Join us as we explore crucial beginner DTF tips that will guide you through this exciting world of printing.

Exploring the realm of Direct-to-Film (DTF) printing offers a fresh perspective for those interested in fabric design and customization. Often referred to as film transfers, this method involves creating vibrant prints directly onto a special film, which can then be effectively applied to textiles. For novices eager to delve into this art, understanding the essential techniques behind DTF printing can be incredibly beneficial. By familiarizing yourself with optimal practices and insights, you can significantly elevate your craft and produce remarkable results. In this discussion, we will unveil some critical strategies that every aspiring DTF artist should know.

A Deep Dive into DTF Printing Techniques

Direct-to-Film (DTF) printing, a process that leverages specialized films for transferring designs onto various fabrics, can be incredibly beneficial to both novice and experienced printers. Understanding the intricate steps involved in DTF printing is crucial; it encompasses selecting the right film type, configuring printer settings, and applying appropriate heat and pressure during the transfer process. By mastering these techniques, beginners can produce vibrant designs that adhere properly to fabric, enhancing both the look and feel of the finished product.

Exploring different DTF printing techniques not only allows beginners to experiment with their creativity but also to optimize print quality. Techniques such as layering colors, experimenting with textures, and adjusting the ink-to-film ratio can dramatically affect the outcome. Furthermore, employing advanced options like fade and blend effects can help in developing unique designs that stand out in a competitive market.

Key DTF Transfer Tips for Beginners

For those just starting with DTF printing, heed these DTF transfer tips as they will significantly impact your results. Understanding the need for quality materials cannot be overstated; using subpar inks or films can lead to dull prints that do not adhere well. As a beginner, ensure that your inks are DTF-specific and match the requirements of your printer to achieve the best possible outcomes.

Additionally, calibration of your printer should not be neglected. Pay attention to the ink density and print speed as per the manufacturer’s recommendations. A well-calibrated printer not only saves materials but also enhances the overall print quality, ensuring that colors pop and details are sharp on your finished product.

How to Choose the Best DTF Printing Supplies

Choosing quality supplies is a cornerstone of successful DTF printing. High-quality films, inks, and adhesives are paramount. When selecting these materials, consider reputable brands known for their reliability and quality, such as INNOSUB and TechnoPrint. Investing in these products can yield significant returns in the form of vibrant prints and reduced chances of defects.

Moreover, understanding how different supplies can affect your printing process is vital. The variety of available DTF films can cater to various fabric types, offering varying results in texture and print vibrancy. Hence, do not hesitate to conduct trials with different materials to find the perfect match for your intended applications.

The Importance of Pre-Treatment in DTF Printing

Pre-treatment is a critical step in the DTF printing workflow that often gets overlooked. This process involves applying specific chemicals or sprays to fabrics, which enhances adhesion and affects the longevity of the print. To achieve the best outcomes, always follow guidelines for the type of fabric you are working with, as different materials may react differently to pre-treatment solutions.

Neglecting pre-treatment can lead to issues such as peeling or fading, detracting from the quality of your prints. By taking the time to properly pre-treat your fabrics, you set up a seamless transfer that looks professional and lasts longer, ensuring that your efforts yield the desired results.

Maintaining Optimal Print Quality

To ensure consistent high-quality results in DTF printing, regular maintenance of your equipment is essential. This includes cleaning your printer to remove any dust or ink build-up that could interfere with the printing process. Regular check-ups for clogs and ensuring that all components are in working order can prevent costly mistakes and subpar prints.

Furthermore, keeping an accurate log of maintenance activities can help track performance issues over time, allowing you to pinpoint areas needing attention. By integrating a routine maintenance schedule into your printing workflow, you can significantly enhance overall print quality and prolong the life of your equipment.

Staying Updated with DTF Printing Trends

Staying abreast of the latest trends in DTF printing not only informs your practice but can also inspire new design ideas. As printing technology continues to advance, new techniques and materials emerge, offering opportunities to elevate your craft. Following industry blogs, forums, and engaging in community discussions can provide valuable insights and keep your skills relevant.

Additionally, participating in webinars and workshops can expose you to cutting-edge practices and innovative uses of DTF printing technology. Networking with other printing enthusiasts can further enhance your knowledge and give you access to a broader range of ideas, techniques, and opportunities within the industry.

Frequently Asked Questions

What are some essential DTF transfer tips for beginners?

For beginners in DTF printing, essential tips include understanding the DTF process, investing in quality materials, and adjusting your printer settings for optimal performance. Additionally, using DTF-specific inks and properly pre-treating fabrics can significantly improve print quality.

How can I improve the print quality in my DTF printing process?

To enhance print quality in DTF printing, ensure you use high-grade films and inks. Adjust your printer settings according to manufacturer recommendations, and always perform test prints to calibrate color accuracy and adhesion before the final run.

What types of inks are best for DTF printing?

For DTF printing, it’s crucial to use DTF-specific inks as they provide better vibrancy and adherence than regular inkjet inks. These specialized inks enhance print durability and color quality, ensuring professional results.

What are effective DTF printing techniques for beginners?

Effective DTF printing techniques for beginners include properly pre-treating fabrics, experimenting with simple designs, and maintaining your printing equipment. Following proper curing techniques is also essential to secure durable transfers.

Why is pre-treatment of fabric important in DTF printing?

Pre-treatment of fabric is vital in DTF printing as it ensures strong adhesion between the design and the fabric. Each fabric type may require specific pre-treatment methods to prevent issues like peeling or fading.

How can I stay updated on DTF printing trends?

To stay updated on DTF printing trends, engage with online forums, subscribe to industry blogs, and participate in webinars or workshops. Networking with other printing enthusiasts can also provide insights into new techniques and best practices.

| Tip Number | Tips | Details |

|---|---|---|

| 1 | Understand the DTF Process | Familiarize yourself with how DTF printing works, including printing on film and transfer methods. |

Summary

DTF Transfer Tips are essential for anyone looking to excel in the realm of DTF printing. Understanding the process, preferring quality materials, tweaking printer settings, and using specific inks are just the beginning of mastering this innovative printing technique. By following the top ten tips outlined above, beginners can avoid common pitfalls and enhance their skills, thus achieving stunning, professional-quality prints. Consistent practice, maintenance of equipment, and staying abreast of industry trends will further ensure success and satisfaction in DTF printing ventures.