DTF Transfer Paper and Inks: Your Complete Guide

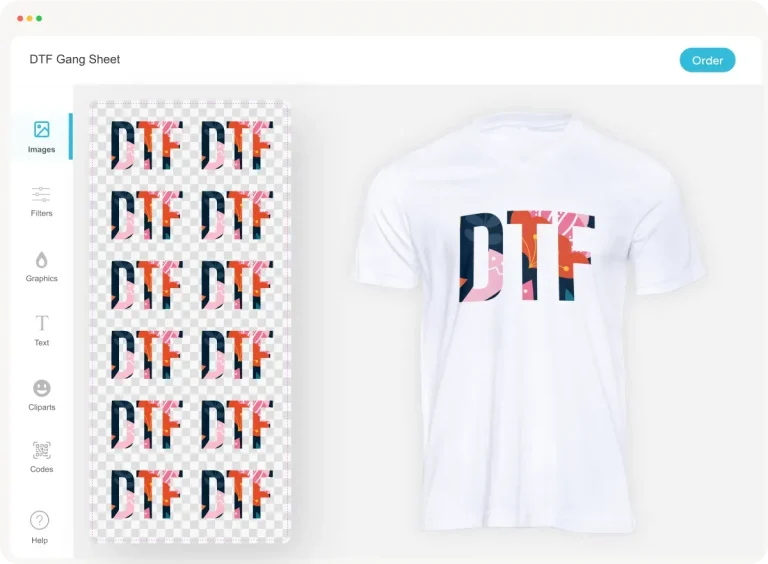

In the innovative world of custom printing, DTF transfer paper and inks play a pivotal role in delivering top-notch results. This Direct-to-Film (DTF) technology is transforming how designs are applied to fabrics, resulting in vivid and long-lasting prints that stand out. Selecting the best DTF transfer paper is essential for ensuring that the images you create come to life with clarity and brilliance. Additionally, pairing the right DTF inks with your chosen paper enhances the overall quality and durability of your prints. In this guide, we will explore crucial aspects of choosing DTF printing supplies to help you elevate your projects to a professional level.

In the realm of digital printing, products like Direct-to-Film (DTF) substrates and ink formulations are crucial for creating high-quality designs. The process of transferring graphics onto various surfaces has improved dramatically, allowing creators to achieve striking results. Understanding the nuances of selecting the most suitable DTF paper and the right inks is vital for anyone interested in custom apparel and creative printing. Moreover, recognizing the impact of different brands and their products can significantly influence the outcome of your prints. This article provides a comprehensive overview of essential factors to consider when navigating the world of DTF materials.

The Importance of Selecting Quality DTF Transfer Paper

Choosing the right DTF transfer paper is paramount for achieving vivid and lasting prints. High-quality DTF papers are formulated to provide a smooth surface that optimizes ink adhesion, ensuring that the colors appear sharp and vibrant. Additionally, the paper’s thickness can affect the transfer process—thicker papers may provide better results on uneven surfaces, while thinner papers are ideal for soft and flexible fabrics. Therefore, understanding the specifications of your DTF transfer paper can enhance the overall quality of your finished product.

Furthermore, the compatibility of transfer paper with your specific printer cannot be overlooked. Many printers have distinct requirements for paper types, and using incompatible paper can lead to subpar results, such as smudging or improper transfer of inks. It’s essential to refer to your printer’s manual to identify the best DTF transfer paper options tailored for optimal performance. Ensuring that your materials work harmoniously will drastically improve the success of your DTF printing projects.

Types of DTF Transfer Paper for Different Fabrics

DTF transfer papers are meticulously designed to cater to various fabric types, and understanding these differences can significantly elevate your printing outcomes. For instance, light fabric DTF papers are perfect for pastel or white garments, as they allow colors to shine through with remarkable clarity and richness. In contrast, dark fabric DTF papers feature a specific white backing that enhances color vibrancy on darker clothing, providing an excellent solution for complex designs. Recognizing these options will enable you to select the most suitable transfer paper for your specific needs.

In addition to color considerations, the texture of the fabric plays a crucial role in the effectiveness of the transfer. For instance, silky or smooth fabrics may benefit from lightweight DTF transfer paper to maintain their luxurious appearance, while heavier, textured fabrics might require more robust options that can withstand the rigors of heat pressing. Assessing the characteristics of both the paper and the fabric you plan to print on will assist you in making informed decisions and ultimately improve the quality of your prints.

What to Look for When Choosing DTF Inks

Selecting the right DTF inks is critical for producing high-quality transfers, as inks play a significant role in the vibrancy and longevity of printed designs. DTF inks are primarily formulated as pigment-based and water-based inks, which not only provide a wider color gamut but also result in enhanced durability against washes and wear. The concentration of pigments in DTF inks is another crucial factor—inks with higher pigment concentrations deliver more robust colors and improved heat transfer results, which can dramatically affect the final appearance of your prints.

Moreover, the type of DTF inks you choose should align with your printer’s specifications. Not all printers operate effectively with every type of ink; therefore, confirming compatibility is essential to avoid printing issues, such as clogging nozzles or inconsistent color application. By investing time in researching the various brands and their formulations, as well as consulting user reviews, you can significantly up the quality of your prints and ensure that the inks you select truly meet your project demands.

Understanding Ink Quality: Brand Matters

The brand of DTF ink can have a profound impact on the quality of the printed results. Renowned brands often adhere to stricter quality control measures in their manufacturing processes, which leads to higher reliability and consistency in their products. High-quality DTF inks exhibit better adhesion to transfer papers and offer superior durability when subjected to washing or abrasion. Therefore, investing in reputable brand inks could be the difference between a vibrant, long-lasting print and one that fades or peels over time.

It’s also noteworthy that different brands may offer unique formulations tailored for specific printing temperatures or fabric types. For instance, some brands might have specially formulated inks that perform better on cotton versus synthetic fabrics, providing superior washability and color retention. As you embark on your DTF printing journey, scrutinizing user experiences and expert reviews will help you navigate the myriad of options available, ensuring that your chosen inks complement your overall printing strategy.

Key Factors to Consider in DTF Printing Supplies

Successful DTF printing extends beyond merely selecting transfer paper and inks; it also involves comprehending the complete ecosystem of DTF printing supplies. Printers, heat presses, and pretreatment solutions are all integral components that contribute to the overall effectiveness of your printing. For example, utilizing a high-quality printer endowed with precision capabilities ensures that ink is applied correctly, while an efficient heat press guarantees optimal transfer results. Each element must work in unison to maximize the quality of your final output.

Moreover, considering the specific needs of your projects can guide your choices in DTF printing supplies. If you frequently work with a variety of fabric types or anticipate using bold colors, selecting versatile inks and papers becomes crucial. Always prioritize quality over quantity; investing in superior materials will yield better prints, elevating your projects from amateurish to professional. Thoroughly researching each aspect of your supplies will empower you to make educated decisions as you navigate the DTF printing landscape.

Expert Tips for Improving DTF Printing Results

Improving results in DTF printing isn’t solely about the materials you use; it also involves refining your technique. Understanding the optimal heat press temperature and duration is essential for ensuring proper ink transfer. Each fabric type can react differently to heat, so experimenting to find the perfect settings for your specific combination of transfer paper, ink, and fabric is highly recommended. Misjudging these elements can lead to issues like incorrect adhesion or burnt designs, so taking the time to find your ideal settings is crucial.

Additionally, it’s beneficial to conduct test prints before diving into larger projects. This practice allows you to assess color accuracy, fabric compatibility, and overall transfer quality in a low-stakes environment. Moreover, seeking advice from seasoned DTF printers and engaging with online communities can provide valuable insights and techniques that may enhance your results. By gathering tips and tricks from others who are experienced in DTF printing, you can improve your skills and ensure that your prints reflect your creative vision.

Frequently Asked Questions

What factors should I consider when choosing DTF transfer paper and inks?

When choosing DTF transfer paper and inks, consider printer compatibility, fabric type, and the quality of materials. Ensure that the DTF transfer paper is suitable for your specific printer model, and select DTF inks known for their vibrancy and durability. High-quality materials are essential for achieving the best print results.

What is the best DTF transfer paper for dark fabrics?

The best DTF transfer paper for dark fabrics is the type that features a white backing. This design allows the images to stand out vividly against darker materials, ensuring vibrant results. Make sure to choose high-quality papers from reputable manufacturers to enhance your printing outcomes.

How do DTF inks affect print quality?

DTF inks greatly influence print quality due to their formulation and pigment concentration. High-quality DTF inks that are pigment-based and water-based provide vibrant colors and durable prints. Using inks specifically designed for DTF printing ensures the best results and enhances the longevity of your designs.

Can I use any DTF transfer paper with any DTF inks?

No, not all DTF transfer paper is compatible with every type of DTF inks. It’s crucial to choose transfer papers and inks that are specifically designed for each other. Always check manufacturer guidelines to ensure that both your DTF paper and inks work harmoniously for optimal performance.

What is the importance of brand when selecting DTF inks?

The brand of DTF inks is important as it can significantly impact the quality of your prints. Reputable brands typically have strict quality control, leading to better results and reliability. Research user reviews and recommendations to choose trusted brands that enhance your DTF printing experience.

How can I determine the best DTF transfer paper for my projects?

To determine the best DTF transfer paper for your projects, consider the type of fabric you are using, read user reviews, and gather insights from expert comparisons. Look for papers specifically designed for your intended fabric color (light or dark) to achieve optimal print quality and durability.

| Key Factor | Considerations |

|---|---|

| DTF Transfer Paper Quality | Select high-quality paper that is compatible with your printing equipment, consulting the manufacturer’s guidelines. |

| Types of DTF Paper | Choose ‘Light Fabric DTF Paper’ for lighter fabrics and ‘Dark Fabric DTF Paper’ for darker materials. |

| Ink Selection | Use pigment-based, water-soluble inks to ensure vibrant colors and durability, ensuring compatibility with your printer. |

| Brand Impact | Opt for reputable brands known for quality control to enhance reliability in your prints. |

| Considerations for Fabrics | Different fabrics may require various types of DTF materials for optimal results, so always consider the fabric type. |

Summary

DTF transfer paper and inks are essential components in the world of modern printing, as they play a pivotal role in the quality and vibrancy of the finished product. By selecting the right materials, you can ensure that your prints not only look stunning but also last through multiple washes and wears. Understanding the nuances of paper types, ink quality, and compatibility will guide you in making informed decisions that enhance your overall printing experience. High-quality DTF transfer materials are worth the investment for anyone looking to create professional-grade designs.