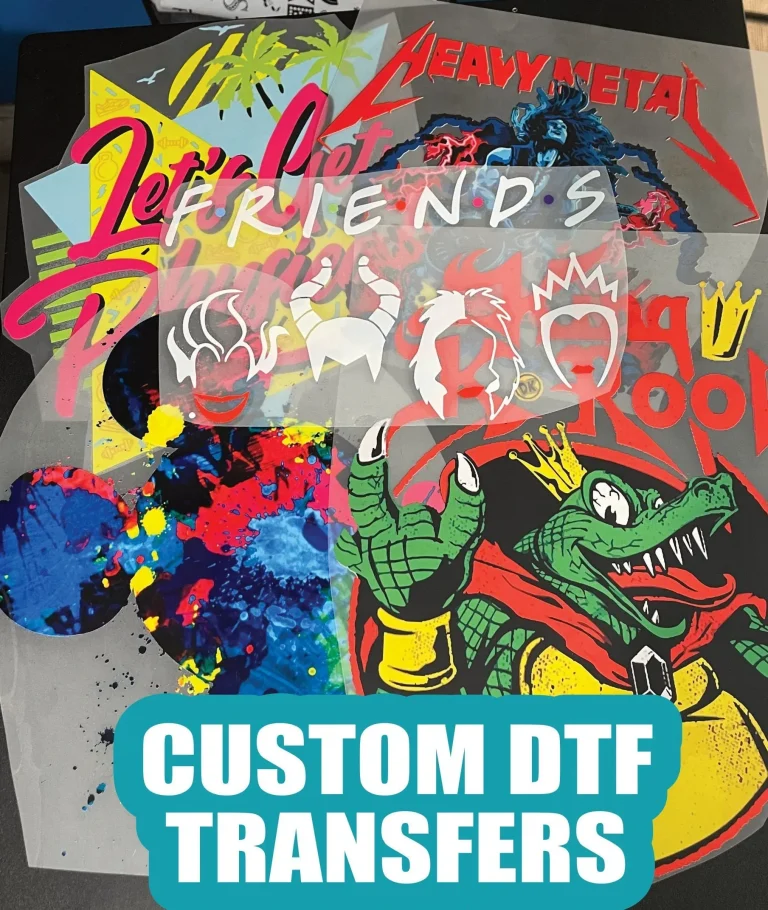

DTF Supplies: Unleash Your Creativity in Printing

DTF supplies are revolutionizing the way artists and businesses approach fabric printing. This innovative method, known as Direct to Film (DTF) printing, utilizes specialized materials such as DTF transfer films and DTF inks to create vibrant designs that adhere seamlessly to various fabrics. With the aid of a reliable heat press machine and adhesive powder, you can achieve professional-quality results that endure the test of time, even after multiple washes. In this guide, we will delve into essential DTF supplies, offering insights and tips to help you master this exciting printing technique. Get ready to unleash your creativity and explore the endless possibilities of DTF printing!

Often referred to as Direct to Film printing, DTF technology is reshaping the landscape of fabric decoration and design. It employs a unique process that combines film, specialized inks, and adhesives for an efficient and high-quality transfer of images onto textiles. The key components include transfer films, vibrant water-based inks, and a heat press machine to set the designs firmly into the fabric. By utilizing adhesives in the process, this technique ensures that prints not only look stunning but also last longer. As we delve deeper into this versatile printing method, you’ll discover how these innovative supplies are paving the way for personalized creations in fashion and beyond.

Understanding the Basics of DTF Printing

DTF printing, or Direct to Film printing, is a revolutionary technique that transforms how designers and crafters approach fabric printing. Utilizing special transfer films designed to capture vibrant colors, DTF printing allows users to print intricate designs directly onto a variety of fabrics. This method stands out thanks to its flexibility and cost-efficiency, particularly for those looking to create custom designs or small runs without the financial burden that traditional methods can impose.

One of the fundamental advantages of DTF printing is its versatility. It supports a range of fabric types, including cotton, polyester, and mixed blends. This adaptability is crucial for artists and designers who employ varied materials for their projects. Moreover, the prints maintain their quality and vibrancy, even after repeated washes, making DTF an excellent choice for garments and other fabric-based products.

Key Components of DTF Supplies

To successfully embark on a DTF printing journey, having the right supplies is essential. First and foremost, DTF transfer films form the backbone of this process. These films are coated to retain ink efficiently, enabling seamless transfers to fabrics. Choosing the right film that suits your printer and inks is pivotal, as this will dramatically impact the quality and durability of your final product.

In addition to transfer films, DTF inks play a crucial role in the printing process. Typically water-based and specifically formulated for DTF applications, these inks deliver vibrant, bold colors that resonate with consumers. It’s important to source high-quality DTF inks from reputable vendors to ensure that the prints remain vivid and intact, even after multiple cleans. Together, these components form the essential toolkit for any DTF printing enthusiast.

Importance of High-Quality Adhesive Powder

Adhesive powder is a critical element in the DTF printing process. It serves as the bonding agent that secures the ink to the fabric, ensuring that designs withstand wear and washing. When applied while the ink is still wet, the adhesive powder creates a lasting fusion once cured with heat. This powder ensures a smooth transfer without any peeling or fading over time, making it a vital supply for achieving professional-grade prints.

Selecting an appropriate adhesive powder is important as different formulations cater to various types of fabrics and printing demands. Whether you’re working with a lightweight cotton tee or a more robust polyester blend, the correct adhesive can enhance the overall quality and durability of your prints. Therefore, understanding the properties of adhesive powders and how they interact with other DTF materials is necessary for any successful printing endeavor.

The Role of a Reliable Heat Press Machine

A heat press machine is indispensable for transferring designs from DTF films onto fabrics. This equipment applies heat and pressure in a controlled manner, ensuring that the prints adhere correctly without damaging the materials. When choosing a heat press, look for a device that offers adjustable temperature and pressure settings. These features will allow you to tailor the settings according to different fabric types and designs, enhancing the success of your printing projects.

Furthermore, investing in a reliable heat press machine can significantly reduce the risk of misprints and ensure consistent results across various projects. A well-calibrated heat press not only makes the task easier but also provides peace of mind, knowing that your designs will be transferred impeccably each time. This critical tool ultimately contributes to the overall quality and professionalism of your printed items.

Best Practices for Achieving Stunning DTF Prints

Achieving high-quality prints through DTF requires attention to detail and adherence to best practices. One key step is preparing the fabric before starting the printing process. Ensuring that the surface is clean and free from debris is essential, as contaminants can affect the print’s adhesion and longevity. Pre-treating fabrics may also enhance the vibrancy of colors in the final design.

Additionally, following manufacturer guidelines for all supplies, including DTF transfer films and inks, can help users avoid common pitfalls. These guidelines provide specific temperature, pressure, and curing time recommendations, which are vital for ensuring optimal results. Moreover, conducting test prints is crucial for fine-tuning settings and materials before embarking on full production runs.

Exploring Trends in DTF Printing

The DTF printing industry is rapidly evolving in response to consumer demand for personalized products. With the rise of online platforms and social media, users can easily market and sell their unique DTF printed items. This trend has been further fueled by advancements in DTF technology, which have improved print quality and made supplies more accessible to hobbyists and professionals alike.

Additionally, consumers are increasingly drawn to custom designs, which has encouraged businesses to invest in DTF printing capabilities. The flexibility of DTF allows for quick prototyping and customization at lower costs compared to traditional printing methods. This trend signifies a promising future for DTF printing, as it accommodates an array of creative projects across various industries, including fashion, home décor, and promotional materials.

Frequently Asked Questions

What are DTF supplies and why are they important for DTF printing?

DTF supplies include essential items like DTF transfer films, DTF inks, adhesive powder, and heat press machines. These supplies are crucial as they directly affect the quality and durability of the prints produced during the DTF printing process.

How do I choose the right DTF transfer films for my projects?

When selecting DTF transfer films, look for those that are compatible with your specific DTF inks and printer. Prioritize films with strong adhesive layers and excellent durability to ensure successful transfers and vibrant, long-lasting prints.

What type of DTF inks should I use for the best results?

Always opt for high-quality, water-based DTF inks formulated specifically for use with DTF transfer films. Reputable suppliers ensure that their inks maintain color vibrancy and adherence post-wash, which is crucial for fabric printing.

Can I use any heat press machine for DTF supplies?

Not all heat press machines are suitable for DTF printing. Ensure your heat press has adjustable temperature and pressure settings, which will help achieve optimal bonding between the transfer film and fabric.

What role does adhesive powder play in the DTF printing process?

Adhesive powder is vital in DTF printing as it helps bond the ink on the transfer film to the fabric. It should be sprinkled on the wet ink before curing to ensure a strong adhesion that lasts even after washing.

What are some best practices to follow when using DTF supplies?

To achieve high-quality prints with DTF supplies, ensure your fabric is clean and debris-free, use high-quality transfer films and inks, follow manufacturer guidelines for settings, and conduct test prints to refine your process.

| Key Component | Description | Importance |

|---|---|---|

| DTF Transfer Films | Specially coated films for ink transfer. | Foundation for achieving quality prints. |

| DTF Inks | Water-based inks designed for DTF films. | Ensure vibrant and durable prints. |

| Adhesive Powder | Bonds the ink to the fabric during transfer. | Critical for successful prints. |

| Heat Press Machine | Machine for transferring designs to fabric. | Essential for controlling the transfer quality. |

Summary

DTF supplies are essential for anyone looking to dive into the world of Direct to Film printing, a revolutionary method that has transformed the way we approach fabric design. This printing technique combines creativity with cutting-edge technology to produce high-quality, durable prints that stand out in today’s market. The right DTF supplies, such as transfer films, inks, adhesive powder, and a heat press machine, are crucial for achieving the best results. By understanding the components and best practices involved, creatives can unlock their full potential, delivering unique designs that resonate with audiences, and elevate their products in the competitive landscape of fashion and home décor.