DTF Supplies: The Ultimate Guide for Successful Printing

DTF supplies are revolutionizing the garment printing landscape, offering a cutting-edge solution for creators and businesses alike. With Direct-to-Film (DTF) technology, you can achieve vibrant and long-lasting prints on a variety of fabrics, making it a favorite among custom apparel makers. Essential DTF supplies include high-quality DTF printers, specially formulated DTF ink, and durable transfer films, all of which contribute to superior print quality and performance. Moreover, utilizing a heat press for DTF applications ensures that designs adhere seamlessly to garments, enhancing their overall appeal. This comprehensive guide will delve into every aspect of DTF supplies, equipping you with the knowledge to make informed decisions and elevate your printing projects.

When it comes to modern fabric decoration methods, Direct-to-Film (DTF) materials stand out for their efficiency and effectiveness. This innovative approach employs specialized printing technology to effortlessly transfer designs onto textiles, paving the way for unique, personalized garments. Essential tools such as a dedicated DTF printer, quality ink formulated specifically for this process, and high-grade transfer films come into play, ensuring exceptional results. Heat application techniques via heat presses further enhance the durability and vibrancy of printed designs. As you explore this exciting field of print technology, understanding the nuances of DTF supplies will be crucial to your success in this dynamic market.

The Importance of Choosing the Right DTF Printer

Selecting the right DTF printer is essential for achieving high-quality designs and prints that can captivate your target audience. A dedicated DTF printer, such as those from the Epson SureColor series, can greatly enhance your printing capabilities. These printers are designed to deliver exceptional color accuracy and detail, ensuring that your printed designs look vibrant and professional. Investing in a quality DTF printer not only improves the output but also streamlines your overall workflow, reducing issues commonly faced in printing.

Moreover, the features of a DTF printer can significantly impact your production efficiency. For example, some printers offer high printing speeds and the ability to handle larger media sizes, allowing you to scale your operations as demand increases. When choosing a DTF printer, consider factors such as print resolution, ink compatibility, and maintenance requirements, all of which will play a vital role in your printing success and business growth.

Understanding DTF Ink and Its Impact

DTF ink is a critical component in the Direct-to-Film printing process, as it directly influences the quality and durability of the final prints. Formulated specifically for DTF printing, this water-based ink provides excellent flexibility, allowing for vibrant colors and intricate designs to come to life on various fabrics. Top brands like Rowmark and Kiwo offer high-performance inks that are engineered to deliver long-lasting results, making them popular choices among professionals in the industry.

Additionally, using high-quality DTF ink reduces the risk of washing or fading issues that can deter customers from repeat business. The right ink enhances not just the visual appeal but also the tactile feel of the printed material, providing a soft, comfortable finish that customers appreciate. Therefore, selecting the best DTF ink is crucial for maintaining a competitive edge in the garment decoration industry.

Choosing the Right Transfer Film for DTF Printing

The choice of transfer film significantly impacts the quality of DTF prints. Transfer films come in various types, such as matte, glossy, clear, or opaque, and each offers distinct advantages depending on the design and the fabric used. Opting for the right thickness and quality not only supports the adhesion of the ink but also contributes to the overall durability of the transfer. For intricate designs or delicate fabrics, a thinner film may provide better detail retention, while thicker options might be preferred for heavier materials.

It’s also important to consider the compatibility of the transfer film with the DTF ink you are using. The combination of high-quality transfer film and the right DTF ink can lead to superior adhesion and longevity, ensuring that your prints can withstand repeated washing without fading or peeling. Therefore, investing time in researching and testing different transfer films will help you achieve optimal results and client satisfaction.

The Role of Adhesive Powder in DTF Printing

Adhesive powder is an integral part of the DTF printing process, serving as the binding agent that ensures the longevity of transfers on garments. This powder is applied before heat pressing, enabling a strong bond between the ink and the fabric. High-quality adhesive powders are specially designed to work with DTF inks, providing an effective solution to prevent issues like lifting or fading of the prints over time.

Selecting the right type of adhesive powder can enhance the performance of your DTF prints significantly. Products that are too coarse or low-quality can lead to poor adhesion and increased likelihood of wear. Therefore, it’s essential to choose adhesive powders specifically labeled for DTF use, as they will provide optimal sticking power and durability, thereby assuring your customers of high-quality products that last.

Investing in a Reliable Heat Press for DTF Printing

A reliable heat press machine is essential for the DTF printing process, as it applies the necessary heat and pressure to transfer designs properly onto garments. When selecting a heat press, consider features such as adjustable temperature settings, consistent heat distribution, and pressure controls. These aspects are crucial to achieving uniform results across various fabric types and thicknesses, ensuring your prints look professional every time.

Additionally, the right heat press can help minimize common issues such as inconsistent transfer quality, peeling, and misalignment. Investing in a reputable brand ensures that you get a machine built for durability and performance, which can handle high-volume production demands without compromising on quality. Moreover, regular maintenance of your heat press will further enhance its longevity and effectiveness, making it a cornerstone of your DTF printing setup.

Staying Current with Market Trends in DTF Printing

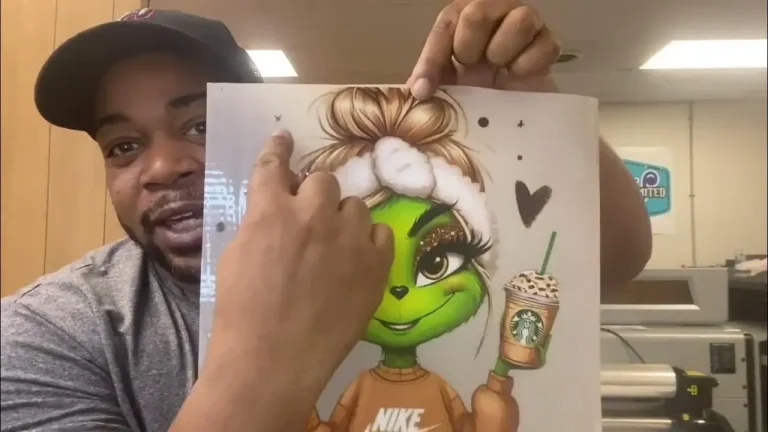

As the garment decoration industry continues to evolve, staying abreast of market trends is vital for any business involved in DTF printing. The demand for personalized apparel is on the rise, driven by consumers seeking unique, customized items. This presents a lucrative opportunity for businesses that can adapt quickly to market changes, incorporating new designs and printing techniques to attract a diverse customer base.

Furthermore, understanding emerging trends can help you effectively market your DTF services, leveraging social media and online platforms to showcase your work. Engaging with potential customers through visually appealing content can boost your brand’s presence, encouraging more people to explore your offerings in the growing custom clothing market. By remaining agile and responsive to these trends, you lay the groundwork for lasting success in DTF printing.

Frequently Asked Questions

What are the essential supplies required for DTF printing?

To successfully engage in DTF printing, you’ll need several essential supplies including a DTF printer, DTF ink, transfer film for DTF, adhesive powder, and a reliable heat press for DTF. Each of these components plays a vital role in producing high-quality prints on various fabrics.

How does a DTF printer differ from traditional printers?

A DTF printer is specifically designed for Direct-to-Film printing, utilizing a specialized inkjet mechanism to deliver vibrant prints onto transfer films. Unlike traditional printers, DTF printers require DTF ink and are optimized for the unique requirements of the DTF process, ensuring better color accuracy and adhesion.

What type of DTF ink should I use for best results?

For optimal results in DTF printing, it is crucial to use high-quality, water-based DTF ink. Brands like Rowmark and Kiwo are popular choices as they are specifically formulated for DTF, providing flexibility, durability, and vibrant color output.

How do I select the right transfer film for DTF printing?

Choosing the right transfer film for DTF printing involves considering the thickness and type of film, whether clear or opaque. The quality of the transfer film directly impacts adhesion and durability, so select films that are specifically designed for DTF processes to achieve the best results.

Why is a heat press important in DTF printing?

A heat press for DTF printing is essential because it applies the necessary heat and pressure to transfer the print from the film to the fabric. A reliable heat press allows for precise temperature control and even distribution of heat, minimizing issues such as peeling or fading of prints.

What kind of design software is recommended for creating DTF prints?

Recommended design software for DTF prints includes industry standards such as Adobe Illustrator and CorelDRAW. These programs offer robust tools for creating detailed graphics compatible with DTF printers, ensuring high-quality outputs and precision in design.

| Key Supplies for DTF Printing | Description |

|---|---|

| DTF Printer | Essential for high-quality prints. Recommended models include the Epson SureColor series. |

| DTF Ink | Specially formulated, water-based inks like Rowmark and Kiwo ensure durability and color vibrancy. |

| Transfer Film | Used to transfer designs onto garments, available in clear and opaque options. |

| Adhesive Powder | Binds ink to fabric during heat transfer. Essential for longevity of prints. |

| Heat Press | Applies necessary heat and pressure for successful transfers, influencing print quality. |

| Design Software | Programs like Adobe Illustrator and CorelDRAW help in creating compatible designs. |

Summary

DTF supplies are crucial for anyone looking to succeed in the burgeoning field of Direct-to-Film printing. This innovative technology allows printers to transfer vibrant and intricate designs onto various fabrics, making it ideal for custom apparel. To excel in this niche market, you need to equip yourself with the right DTF printer, high-quality inks, suitable transfer films, adhesive powders, a reliable heat press, and proficient design software. By focusing on these key supplies and keeping informed about market trends, you can create unique, high-quality garments that meet consumer demand. Staying engaged with educational resources will further enhance your skills, ensuring your success in the competitive landscape of DTF printing.