DTF Supplies: Maximize Your Creativity with Must-Have Tools

DTF supplies play a crucial role in the rapidly evolving landscape of custom garment printing, specifically within the realm of Direct to Film printing technology. This innovative method enables creators to produce high-quality prints with vibrant colors and intricate designs that can adhere to various fabrics. Whether you’re a small business embarking on a new venture or a hobbyist exploring your artistic potential, understanding the essential DTF supplies can elevate your creative output significantly. From investing in a reliable DTF printer to utilizing adhesive powder for DTF applications, each component is vital in achieving stunning results. This guide will delve into the must-have supplies that will maximize your creativity and transform your printing projects into mesmerizing works of art.

In the dynamic world of custom apparel production, utilizing essential materials for Direct to Film printing, often referred to as DTF, is key to unlocking your creative potential. This cutting-edge printing technology allows artists and businesses to transfer crisp, colorful imagery onto fabric with ease and efficiency. For those venturing into this realm, familiarizing oneself with necessary items like DTF printers, transfer films, and specialized adhesive powders will ensure successful outcomes. Moreover, with the right heat press machine for DTF, you can guarantee a seamless and high-quality transfer process. This article will cover the vital tools that every printer should consider for their project success.

Understanding DTF Printing Technology

DTF, or Direct to Film printing, is revolutionizing the custom garment industry by allowing vibrant and durable designs to be transferred onto fabrics. This innovative technology utilizes specialized printers to print designs onto a film that is then heat pressed onto materials. As a result, DTF printing stands out for its capability to manage intricate patterns with ease, making it an artist’s dream for creating personalized apparel.

Beyond just the visual appeal, DTF technology is celebrated for its compatibility with a variety of fabrics. Unlike traditional methods, it allows for smooth and seamless application, reducing the chances of cracking or fading over time. As printers become more affordable, many small businesses and hobbyists are embracing this method, leading to a surge in creativity within the garment printing sector.

Essential DTF Supplies for Success

To get the most out of your DTF printing projects, investing in essential supplies is critical. A quality DTF printer is the backbone of this operation, specifically designed to handle the printing of specialized DTF inks. Selecting the correct model can dramatically impact the vibrancy and durability of your prints.

In addition to the printer, the type of transfer film you choose plays a significant role in the quality of your output. High-quality films ensure that designs maintain their sharpness and clarity once transferred. Combined with the right adhesive powder, which helps to bond the ink to the fabric, you’ll find that the right supplies influence the overall success of your DTF projects.

Key Features of a DTF Printer

When selecting a DTF printer, there are several features to consider that can enhance your overall printing experience. First, think about the ink technology; printers that utilize high-quality DTF inks excel in producing vibrant and long-lasting colors. Additionally, the size and compatibility of the printer with various film types can expand your creative options.

Another important feature to look for is the print speed and resolution. A faster printer can increase production efficiency, while a high resolution will ensure that even the most intricate designs are printed with detail. Understanding these features will guide you in making an informed choice that aligns with your creative goals.

Importance of Adhesive Powder in DTF Printing

Adhesive powder is a crucial component in the DTF printing process, acting as a binding agent that ensures the printed design adheres to the fabric during heat transfer. Choosing the right adhesive powder specifically formulated for DTF applications can make a huge difference in the final quality of the print. If you encounter clumping or uneven application, it may signal that the powder is not suited for your particular DTF setup.

Additionally, the application technique is key. Properly applying the adhesive powder allows for a smoother transfer, resulting in vibrant prints without excessive buildup. Understanding how much powder to use and the application process can enhance your designs and ensure they stand the test of time.

Choosing the Right Heat Press Machine

A dependable heat press machine is essential for executing successful DTF transfers. When looking to invest in a heat press, consider the features that cater to your specific needs, such as adjustable temperature settings and even heat distribution. A dual heat press can also provide greater flexibility, allowing you to work on multiple projects simultaneously.

For optimal results, it’s critical to ensure that the pressure applied during the heat transfer is consistent. Machines with digital displays can help you monitor both temperature and time accurately, contributing to better consistency in your finished products. The right heat press machine will not only improve the quality of your DTF prints but also streamline your production process.

Creative Applications of DTF Printing

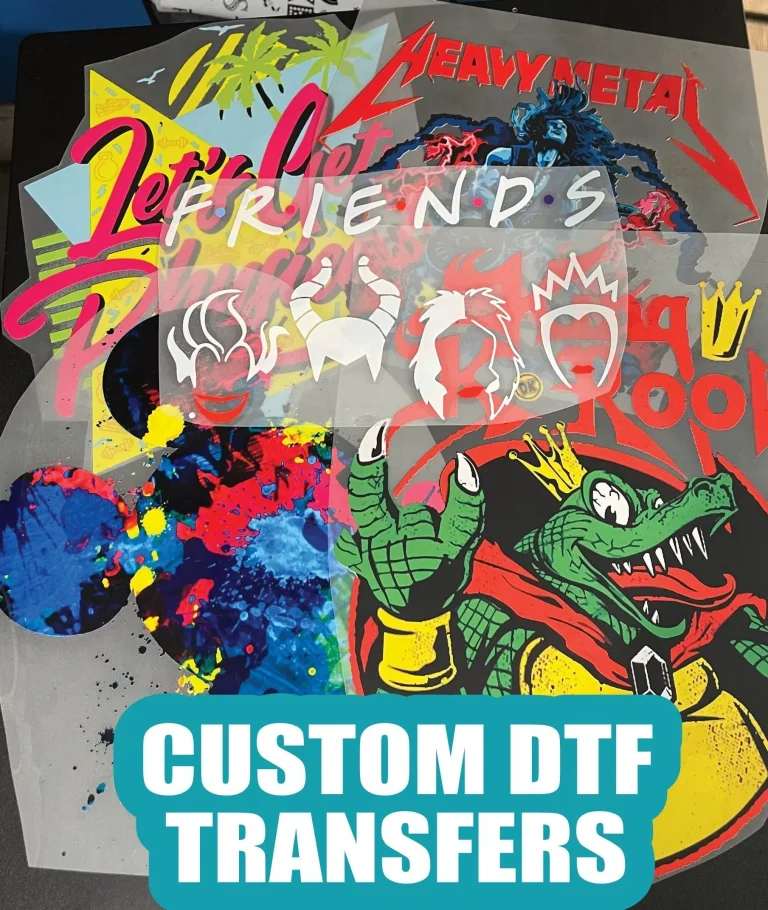

DTF printing opens up a world of creative possibilities for garment decoration. With its ability to apply intricate and colorful designs on various fabric types, artists and businesses can explore unique textures and visual effects. Whether you’re looking to create bold patterns, realistic images, or custom text, DTF is suited for a broad range of artistic applications.

Moreover, the customization potential offered by DTF technology allows creators to cater to niche markets. Businesses can offer personalized apparel, supporting trends such as custom team jerseys or fashion-forward streetwear. By leveraging DTF printing, you can elevate your designs and meet the diverse needs of your customers, fostering a space for innovation within your brand.

Frequently Asked Questions

What are the essential DTF supplies needed for Direct to Film printing?

To successfully execute DTF printing, you need essential DTF supplies including a specialized DTF printer, high-quality transfer film, adhesive powder specifically designed for DTF, a reliable heat press machine, and appropriate fabric. All these components work together to ensure vibrant and durable prints.

How does a DTF printer differ from other printers?

A DTF printer is specifically designed for Direct to Film printing, utilizing DTF inks that adhere well to transfer films and garments, unlike standard printers that may lack this specialized technology. This ensures the best print quality and durability necessary for garment decoration.

What role does adhesive powder play in DTF printing?

Adhesive powder is a critical component in the DTF printing process, applied to the printed design to ensure proper transfer adhesion to the fabric during heat pressing. Using high-quality adhesive powder designed for DTF prevents issues like clumping and enhances transfer effectiveness.

How do I choose the right heat press machine for DTF printing?

When selecting a heat press machine for DTF printing, look for features such as adjustable temperature and pressure settings, along with a suitable size for your designs. Consider dual heat press models for greater versatility, and opt for machines with digital displays for precise control.

What types of fabrics are best for DTF printing?

DTF printing works best on fabrics like cotton and cotton blends, which support vibrant ink adherence and durability. Choosing high-quality fabrics can improve the overall finished product. Additionally, consider organic or recycled materials to cater to eco-conscious consumers.

Is DTF printing suitable for small businesses and hobbyists?

Yes, DTF printing technology has become increasingly accessible and affordable, making it a great option for both small businesses and hobbyists looking to create vibrant and custom garment designs. The adaptability and ease of use of DTF supplies enable a wide range of creative possibilities.

| Key DTF Supplies | Description |

|---|---|

| DTF Printer | Essential for high-quality prints using DTF ink. |

| Transfer Film | High-quality PET film ensures sharp designs; thickness affects results. |

| Adhesive Powder | Used before heat transfer; choose DTF-specific powders for best results. |

| Heat Press Machine | Critical for even heat application; look for adjustable settings. |

| Design Software | Software like Adobe Illustrator aids in preparing print-ready graphics. |

| High-Quality Fabric | Cotton and blends yield top results, with a focus on sustainability. |

Summary

DTF supplies are crucial for unleashing your creativity in custom garment printing. By carefully selecting quality materials, such as specialized DTF printers, high-grade transfer films, and reliable adhesive powders, you can enhance the overall quality of your prints. Additionally, investing in an efficient heat press machine and effective design software plays a significant role in achieving stunning results. Moreover, choosing the right fabrics, particularly organic options, adds value and sustainability to your creations. As DTF technology becomes more accessible, those keen on producing unique, personalized garments should fully embrace the essential supplies and techniques that this innovative printing method offers.