DTF supplies: How to choose for beginners and pros

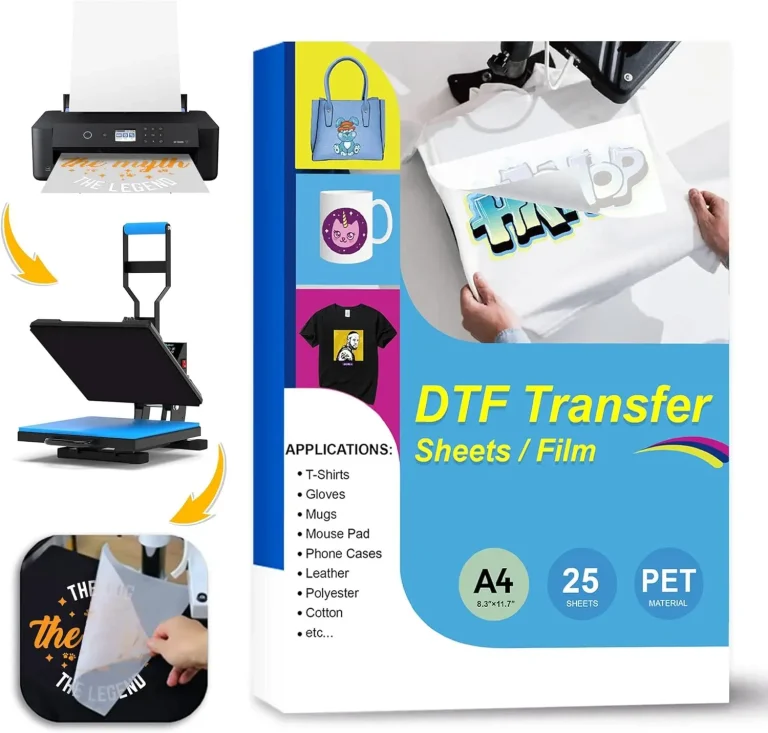

DTF supplies play a critical role in achieving reliable, vibrant transfers for apparel and textiles. Choosing the right DTF printing supplies directly affects color fidelity, durability, and how smoothly your workflow runs. From DTF transfer paper to inks and bonding powder, the compatibility and quality of each component determine final results. Investing in a well-balanced kit that aligns with your DTF printer setup helps reduce waste and avoids costly reprints. By testing your selections and understanding how these materials work together, you can achieve consistent color, wash-fast durability, and a smoother production flow.

In other words, the modern approach to this process relies on cohesive direct-to-film materials that work in harmony. Think of transfer media, inks, and release coatings as a connected chain that shapes color depth, wash durability, and production speed. A well-tuned printer setup, precise heat-press settings, and compatible coatings ensure sharp edges and even transfers across fabrics. Using latent semantic indexing-inspired terms such as direct-to-film consumables, heat-transfer media, and dye- or pigment-based inks helps align this topic with related research and searches. By exploring these related concepts and validating performance with real samples, you can build a flexible, scalable workflow that delivers consistent results.

Choosing the Right DTF Supplies: Balancing DTF Transfer Paper, Inks, and Bonding Powder

Choosing the right DTF supplies means looking for a finely tuned combination rather than chasing the flashiest gadget. The transfer paper should pair well with your inks and bonding powder, while your printer setup needs to stay calibrated for consistent ink laydown. When color fidelity and durability matter, the conversation expands beyond individual items to how they work together. A thoughtful selection anchored by reliable DTF transfer paper, high-quality DTF ink quality, and a dependable bonding powder supports smooth laminations, clean releases, and durable hand-feel on fabrics. In this view, DTF printer setup becomes less about one perfect component and more about a coherent system that reduces misfeeds, misprints, and post-curing issues.

To evaluate, start by testing the transfer paper with a few ink brands you trust, watching for color density, edge sharpness, and bleed control. Keep the ink quality consistent across tests so you can isolate paper behavior. Observe how well the bonding powder adheres at standard heat and time settings, and whether it produces a clean release during lamination. The goal is a harmonious balance where the surface looks vibrant, the image remains sharp after multiple washes, and the workflow remains predictable across runs. Document results and adjust your printer setup, choosing a combination that minimizes reprints and maximizes repeatability.

DTF Supplies That Scale: Optimizing Printer Setup, Ink Quality, and Paper for Home or Small Shop

DTF Supplies That Scale: Optimizing Printer Setup, Ink Quality, and Paper for Home or Small Shop.

DTF supplies a cohesive system: a trusted transfer paper, reliable ink quality, and a bonding powder that holds up under heat pressing. Budgeting here is about long-term value—lower per-transfer costs come from avoiding frequent reprints and choosing paper that behaves consistently across lots, while investing in inks with stable performance. Your DTF printer setup should stay aligned with the chosen media and ink, featuring clean heads, calibrated color profiles, and stable tension to prevent drift. With this foundation, scaling from a few items to a steady workflow becomes practical and repeatable.

(Continuation) crafting a scalable workflow for DTF supplies

Once the core trio is stable, build a validation workflow that mirrors real production. Create a small batch of test designs on a couple of fabrics, log color accuracy, edge definition, and wash resistance, and compare results over several laundering cycles. Ensure your bonding powder settings align with the heat-press schedule you use and tune the printer setup accordingly. By treating DTF supplies as an integrated system and adopting a repeatable testing protocol, you’ll be better prepared to scale from hobby projects to a growing small shop without sacrificing color fidelity or durability.

In practice, this means documenting outcomes, revisiting the balance between transfer paper, inks, and bonding powder, and adjusting along the way. A well-planned starter kit wheels in DTF printing supplies that are compatible with your printer model and allows for predictable results. As you expand, maintain a simple log of settings, fabric types, and wash results so your workflow remains efficient, consistent, and capable of meeting growing demand.

Frequently Asked Questions

What should I look for in DTF printing supplies when choosing DTF transfer paper and inks for a reliable DTF printer setup?

Choose DTF printing supplies that are compatible with your printer and inks. For DTF transfer paper, verify weight (gsm), coating quality, back coatings for ink bleed control, and compatibility with your DTF ink quality and printer model. For ink, check color gamut, dry time, wash-fastness, and consistent nozzle performance. In your DTF printer setup, calibrate color profiles for your specific paper and inks, perform regular maintenance, ensure proper media handling, and maintain stable temperature and humidity. Start with a proven starter kit and test across a couple of fabrics before expanding to larger runs to ensure color fidelity and durability.

How does DTF bonding powder affect adhesion and durability, and how should I evaluate DTF ink quality and DTF transfer paper to ensure reliable transfers?

Bonding powder quality matters: look for uniform particle size, consistent quality, and heat-activation compatibility with your printer setup and inks. Some powders perform better on cotton blends, others on synthetics—choose based on your typical products. When evaluating DTF printing supplies, test bonding powder together with your DTF ink quality and DTF transfer paper by printing, applying powder, curing, and pressing on multiple fabrics, then washing per care guidelines. Adjust heat and time, or powder quantity as needed, to optimize adhesion. Maintain a well-calibrated DTF printer setup and stable environmental conditions to preserve consistency over time.

| Aspect | Key Points |

|---|---|

| Introduction | Choosing the right DTF supplies is about quality and compatibility, which directly affect color fidelity, durability, and workflow. Build a reliable kit that fits your budget and goals to deliver consistent results whether you’re at home or running a small shop. |

| DTF basics | DTF = direct-to-film. A successful setup comes from a well-balanced system—paper, inks, bonding powder, and a calibrated printer—rather than a single miracle product. |

| DTF printing supplies overview | Key categories include transfer paper, inks, bonding powder, and the printer plus maintenance tools. Good supplies are printer-compatible, deliver strong color, and withstand repeated wash cycles; they should match your production pace. |

| Evaluating transfer paper | Consider weight (gsm), coating quality, back coatings controlling ink bleed, and how well paper releases from film during lamination. Test swatches to verify compatibility with your inks and printer. |

| Ink quality and color reliability | Look for color vibrancy and gamut, drying time, wash-fastness, consistency, and nozzle performance. Run tests with the same paper to compare color accuracy and stability across brands. |

| Bonding powder and adhesion | Powder uniformity, heat activation compatibility, and fabric compatibility affect adhesion and transfer cleanliness. Poor bonding powder can cause peels or incomplete transfers. |

| Printer setup | Calibrate color profiles, perform regular maintenance, manage media handling, and control temperature/humidity for consistent results. |

| Budgeting | Focus on long-term value: per‑print cost, durability vs. price, and cross-item compatibility. A single, compatible supplier can simplify purchasing. |

| Testing and validation | Use controlled tests with a standard setup, document color accuracy, edge sharpness, and wash durability, and keep a log of results to compare across runs. |

| Beginner-friendly workflow | Start with a proven starter kit, run small fabric tests, evaluate color/edge/adherence after washing, and expand only after baseline performance is solid. |

| Common mistakes | Avoid non-recommended transfer paper, ignore humidity, and skip calibration. Follow heat/time guidelines and recalibrate when switching major components. |

| Conclusion (summary) | A methodical, testing-driven approach yields the best long-term value in DTF supplies. Build a balanced kit, test and compare, and refine your process to achieve consistent color, sharp detail, and durable transfers. |

Summary

HTML table provided above summarizes the key points about DTF supplies in English.