DTF Supplies: Essential Upgrades for Print Quality in 2023

DTF supplies are revolutionizing the way custom printing is done, especially in 2023, where quality and eco-friendliness are paramount. Direct to Film (DTF) printing, which involves the use of specialized DTF printers, has surged in popularity due to its capability for producing vibrant, detailed prints on various fabrics. Essential supplies like heat press machines, eco-friendly inks, and adhesive powder are critical to ensure optimal results in your printing projects. Whether you’re a professional in the apparel industry or a DIY enthusiast, having the right DTF supplies will empower you to create stunning designs that stand the test of time. This introductory guide aims to provide you with key insights on what you need to elevate your DTF printing experience this year.

Custom film transfer supplies play a fundamental role in the thriving world of textile printing. As the demand for high-quality prints increases, techniques like Direct Film Transfer (DFT) are gaining traction among creators looking to innovate their printing processes. Essential tools such as printing machines, heat application equipment, and sustainable ink options are now indispensable for anyone passionate about their craft. Access to quality materials enables professionals and hobbyists alike to produce intricate designs with impressive durability and color richness. Embracing these advanced transfer supplies not only enhances print quality but also aligns with the growing trend towards environmentally mindful production.

Importance of DTF Printers in Modern Printing

DTF printers are critical for modern custom printing processes, offering unmatched precision and quality. In 2023, innovations in DTF printers have pushed the boundaries of what’s possible, allowing for high-resolution images that capture intricate details with vibrant colors. The capability to print on various fabrics expands creative horizons for artists and businesses alike. Reliable brands such as Epson and Brother have designed printers that not only deliver exceptional printing quality but also ensure durability and efficiency in operation.

Investing in a high-quality DTF printer means having access to state-of-the-art technology that integrates seamlessly with the printing workflow. A robust printer can significantly streamline the process from design to final product, reducing errors and enhancing overall productivity. As DTF printing continues to gain popularity, the demand for these sophisticated printers is on the rise, making it essential for anyone involved in the printing industry to consider upgrading their equipment.

The Role of Adhesive Powder in DTF Printing

Adhesive powder plays a pivotal role in ensuring successful DTF prints, acting as the glue that binds ink to fabric. In recent years, advancements in adhesive technology have led to the development of high-performance hot melt powders that improve adhesion without compromising flexibility. This durability is essential for prints that experience high levels of wear and washing. Today’s powders can accommodate a diverse range of textiles, ensuring that prints retain their vibrant colors and designs over time.

Moreover, the application of adhesive powder enhances the overall versatility of DTF printing. This allows printers to work with different materials, from cotton to polyester blends, expanding the potential applications of printed items. As manufacturers continually innovate, looking for eco-friendly and effective adhesive solutions will further process sustainability, making it easier for businesses to cater to environmentally conscious consumers.

How Eco-Friendly Inks Are Transforming DTF Printing

The shift towards eco-friendly inks in DTF printing is a significant trend for 2023, reflecting a growing awareness of environmental issues within the industry. Eco-friendly inks not only contribute to a reduced ecological footprint but also maintain high-quality prints that meet consumers’ expectations for vibrancy and durability. These water-based inks minimize toxic emissions during production and offer an improved renewable option for printing businesses.

Incorporating sustainable inks into your DTF printing process can also provide an edge in marketing, as more customers seek out brands that prioritize environmental responsibility. With robust formulations designed for excellent washability and color retention, eco-friendly inks allow printers to produce high-impact visuals while complying with environmental regulations and trends. This commitment to sustainability is becoming a key differentiator in the competitive DTF printing landscape.

The Mechanics of Choosing the Right Heat Press Machine

Choosing the right heat press machine is crucial for ensuring effective and flawless transfers from film to fabric. In 2023, advancements in heat press technology mean there’s a wide array of options on the market, from clamshell to swing-away models, each offering distinct advantages. Key features to consider include temperature control, pressure settings, and platen size, which directly impact the quality and consistency of transfers.

Investing in a heat press machine that allows for adjustable settings can significantly enhance your DTF printing experience. With proper heat application, inks adhere better to fabrics, which not only improves the visibility of the prints but also ensures their longevity. As the DTF printing market grows, selecting a reliable and efficient heat press will play a vital role in maintaining the overall quality of your finished products.

Latest Trends and Innovations in DTF Printing

Staying current with trends and innovations is vital for anyone in the DTF printing community. In 2023, the emphasis is on eco-conscious materials and sustainable practices, following a broader industry move towards environmentally friendly solutions. Manufacturers are innovating to create products that are not only effective but also aligned with green initiatives, which resonate well with today’s eco-aware consumers.

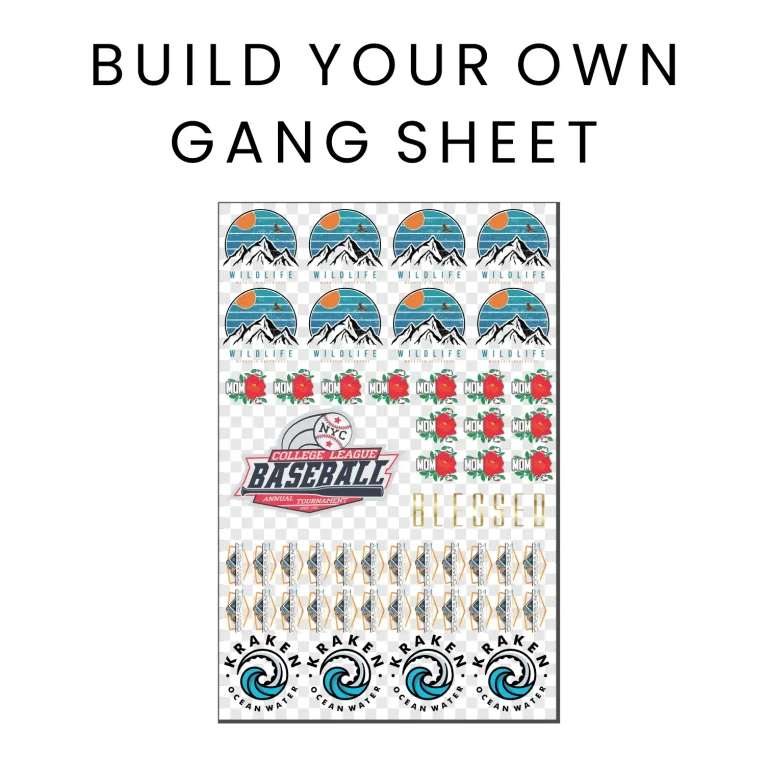

Additionally, customization options are rapidly expanding, allowing for more complex designs and personalization in printing. Techniques like color matching and pre-printed DTF transfer sheets have become commonplace, providing designers with more tools to enhance creativity. As a result, being informed about these trends can greatly impact your ability to attract clients and stay competitive in the evolving marketplace.

Unlocking Creative Potential with DTF Design Software

Efficient design software is the backbone of successful DTF printing projects, enabling creatives to prepare and refine their designs effectively. Programs like Adobe Illustrator and CorelDRAW have evolved to include features specifically tailored for DTF workflows, such as enhanced color management and file compatibility. These advancements allow artists to manipulate their designs precisely for maximum visual impact.

Utilizing specialized software not only streamlines the design process but also enhances the overall quality of the prints produced. With robust tools for layout and design adjustments, printers can explore a wider range of creative possibilities, ensuring customized outputs that meet and exceed client expectations. As software continues to develop, those leveraging these tools will likely gain a competitive edge in the industry.

Frequently Asked Questions

What are the essential DTF supplies needed for successful DTF printing?

To successfully execute DTF printing, essential supplies include a high-quality DTF printer, durable PET film sheets, hot melt adhesive powder, eco-friendly inks, and a reliable heat press machine. Each component plays a vital role in producing vibrant and long-lasting prints.

How does a heat press machine contribute to the DTF printing process?

A heat press machine is crucial in DTF printing as it applies the necessary heat and pressure to transfer the ink from the film onto the fabric. Investing in a high-quality heat press with adjustable settings will ensure optimal transfer results, enhancing print longevity and vividness.

What types of inks are best for DTF printing in 2023?

In 2023, eco-friendly inks have gained popularity for DTF printing due to their vibrant color output and reduced environmental impact. These sustainable inks ensure excellent washability while providing high-quality prints that meet consumer demands for environmentally conscious products.

Can you explain the role of adhesive powder in DTF printing?

Adhesive powder, specifically hot melt powder, is an integral part of DTF printing as it ensures that the ink transfers adhere securely to various fabrics. The latest adhesive technologies provide exceptional bonding capabilities, allowing for flexible and durable prints that withstand washing.

What brands are recommended for DTF printers in the current market?

Leading brands such as Epson and Brother are highly recommended for DTF printers due to their reliability and high-resolution printing capabilities. Additionally, newer models specifically designed for DTF processes are emerging in 2023, providing improved features tailored for seamless printing.

How can design software enhance the DTF printing experience?

Efficient design software, such as Adobe Illustrator and CorelDRAW, is essential for preparing high-quality designs for DTF printing. These programs offer enhanced compatibility and specific features that streamline the DTF workflow, allowing for greater creativity and precision in producing stunning prints.

| Key DTF Supply | Description |

|---|---|

| DTF Printers | Reliable and high-resolution printers from brands like Epson and Brother, essential for quality prints. |

| Film Sheets | High-quality PET film sheets that ensure durability and vibrant colors for transfers. |

| Adhesive Powder | Hot melt powder that provides strong bonding and flexibility for prints. |

| Inks | Eco-friendly inks that offer vibrant colors while being less harmful to the environment. |

| Heat Press Machines | Machines with digital controls and adjustable pressure, crucial for effective transfers. |

| Software Solutions | Design software like Adobe Illustrator and CorelDRAW that enhance layout precision for DTF. |

Summary

DTF supplies are the cornerstone of any successful printing endeavor in 2023. Understanding and procuring the essential tools such as DTF printers, high-quality film sheets, and innovative heat press machines ensures your ability to create stunning prints that stand out in today’s competitive market. As the landscape of custom printing evolves, the importance of eco-friendly materials and effective software solutions cannot be overlooked, further enhancing both the quality and sustainability of your projects. By leveraging the latest DTF supplies, you equip yourself to not only improve your printing capabilities but also to meet the rising consumer demand for responsible production practices.