DTF Supplies: Essential Info for Your Printing Journey

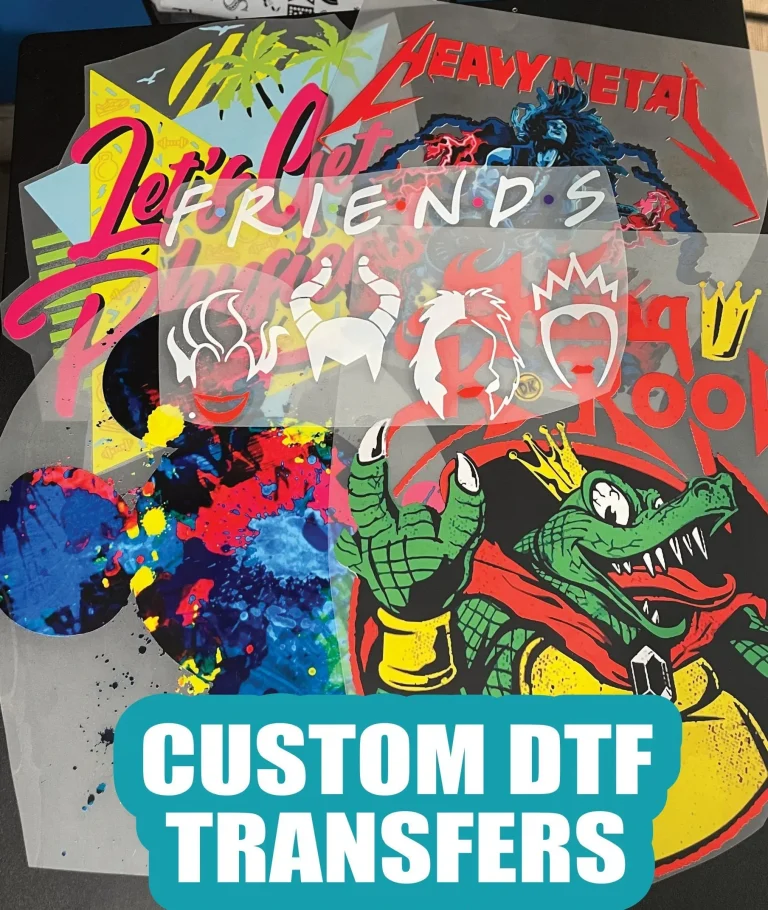

DTF Supplies are essential for anyone looking to dive into the world of custom apparel printing, providing a seamless connection between creativity and efficiency. Whether you’re an experienced professional or just starting your printing journey, understanding the critical components such as DTF printing technology is paramount to achieving vibrant results. A dedicated DTF printer, specialized DTF transfer films, and a reliable heat press for DTF are just a few of the key supplies that determine the quality of your final product. With the right materials, you can create custom designs that resonate with customers, offering both durability and aesthetic appeal. As the demand for unique, high-quality prints grows, so does the importance of equipping yourself with top-notch DTF supplies.

Getting started with Direct-to-Film (DTF) printing supplies opens the door to exciting possibilities in personalized garment creation. This innovative method, which involves transferring detailed images onto various fabrics, promises unparalleled flexibility and high-quality outputs. By utilizing custom transfer films, specially formulated inks, and a precise heat application process through a heat press, anyone can produce stunning apparel designs. Whether you’re planning to print on cotton, polyester, or a blend of materials, understanding the essentials of DTF technology is key to thriving in this growing industry. With the right resources at your disposal, you can elevate your printing capabilities and meet the rising demand for customized clothing.

Understanding DTF Transfer Films

DTF transfer films are an essential component of the Direct-to-Film printing process, acting as a medium on which your designs will be printed before being transferred to fabric. These specialized films are coated in a way that allows the DTF inks to adhere properly, delivering vibrant colors and sharp details. The choice of DTF films can greatly affect the outcome of your prints; thus, selecting options from reputable suppliers is crucial to ensure quality. Top-tier films will offer superior durability and wash resistance, making them a reliable choice for custom apparel.

It’s important to understand that not all DTF films are created equal. Factors such as thickness, coating, and compatibility with diverse fabric types can influence your final results. To achieve optimal adhesion, make sure to conduct tests with your specific DTF printer and inks. Experimenting with different brands and types will help you find the right fit for your printing needs, ultimately enhancing the quality of your custom apparel.

Choosing the Right DTF Printer

Selecting the appropriate DTF printer is pivotal to your printing success. A dedicated DTF printer is engineered to handle pigment-based inks that offer striking color vibrancy while maintaining high image integrity during washes. It’s crucial to choose a printer that features compatibility with DTF transfer films, ensuring seamless integration in your operational workflow. Investing in a high-quality DTF printer not only enhances your printing capabilities but also contributes to the overall longevity and durability of your designs.

When exploring DTF printer options, consider factors like print resolution, speed, and ease of use. Many reputable brands offer models specifically designed for beginners and professional setups alike, so doing thorough research will pay off in your printing journey. Additionally, keep an eye on maintenance requirements and support options from the manufacturer, as these can greatly affect your overall usability and satisfaction.

The Importance of Heat Press Machines in DTF Printing

A heat press machine plays an indispensable role in the DTF printing process by applying the necessary heat and pressure needed for proper transfer of images onto fabric. The right heat press ensures even distribution of heat across the entire design area, which is critical for achieving consistent results. Choosing a high-quality heat press can lead to fewer errors and wastage during the printing process, ultimately enhancing productivity in your custom apparel business.

When selecting a heat press for DTF projects, consider factors like temperature control, pressure settings, and the size of the heating plate. Different materials may require varying temperatures and pressure levels, hence investing in an adjustable heat press will allow you to cater to a diverse portfolio of projects. Regular maintenance and calibration of your heat press will also ensure optimal performance over time, reducing the risk of costly mistakes.

Essential DTF Inks for Brilliant Color Results

Choosing the right DTF inks is essential for achieving brilliant color results in your prints. DTF inks are specially formulated to provide vibrant colors that adhere well to both the transfer films and the fabric. These inks must withstand heat and maintain their quality after multiple washes, making it vital to use only high-quality options that align with the DTF printing process.

Moreover, the right inks can dramatically affect the clarity and vibrancy of your designs. It’s advisable to source inks from reputable suppliers who specialize in DTF technology to ensure that you get the best results for your custom apparel. Conducting tests with different ink brands or formulations can help you gauge compatibility with your chosen films and fabrics, leading to enhanced print quality.

Navigating DTF Printing Challenges

While DTF printing offers many benefits, it also presents several challenges that newcomers must navigate. One of the most significant hurdles is the initial investment required for quality equipment, including printers, heat presses, and essential supplies. The costs can add up quickly, but understanding the long-term value of investing in high-quality DTF materials can help mitigate concerns.

Beyond financial considerations, the steep learning curve associated with DTF technology can be daunting for beginners. Familiarizing oneself with the equipment, understanding the nuances of the printing process, and mastering technique takes time and practice. However, aspiring printers can find great support through online communities, workshops, and tutorials to gain confidence and skills as they navigate the complexities of DTF printing.

Best Practices for DTF Supply Maintenance and Safety

Proper maintenance and safety practices are paramount in ensuring a successful DTF printing experience. Regular equipment upkeep, particularly for your printer and heat press, will help prevent malfunctions and prolong the life of your machinery. Cleaning your printer’s nozzles and heads, as well as ensuring that your heat press plates are spotless, can significantly enhance print quality and reduce the likelihood of errors during transfers.

In addition to maintenance, safety should not be overlooked when working with inks and adhesives. Good ventilation is crucial in your workspace, particularly when handling materials that may emit fumes or dust. Wearing personal protective equipment, such as masks and gloves, can help safeguard against any harmful effects. By adhering to safety guidelines and maintaining your DTF supplies diligently, you create an environment conducive to quality output and personal health.

Frequently Asked Questions

What are the essential supplies needed for DTF printing?

To start your DTF printing journey, you’ll need several essential supplies, including a dedicated DTF printer, specialized DTF transfer films, adhesive powder for bonding, a quality heat press, and high-quality DTF inks. Each of these supplies plays a crucial role in ensuring vibrant and durable prints on various fabrics.

How does a heat press for DTF affect print quality?

A heat press for DTF is critical as it applies the precise heat and pressure required to successfully transfer designs from the DTF transfer films onto fabric. The quality and type of heat press can greatly influence the final print quality, making it vital to choose a reliable model to achieve the best results.

What types of fabrics can be used with DTF supplies?

DTF supplies are versatile and can be used on a wide range of fabrics, including cotton, polyester, and blends. This flexibility makes DTF printing an excellent choice for custom apparel printing that caters to various material types and customer needs.

How do DTF transfer films impact the printing process?

DTF transfer films are specially coated to accept ink and effectively transfer designs onto fabric. The quality of DTF films directly affects the clarity and durability of the print, making it crucial to invest in high-quality transfer films to ensure successful DTF printing results.

What are common challenges faced when starting with DTF printing?

Common challenges when starting with DTF printing include initial setup costs and a steep learning curve. Quality DTF printers and heat presses can be expensive, and getting familiar with the printing process and materials typically requires time and practice.

Why is it important to choose quality DTF inks?

Choosing quality DTF inks is vital as they are formulated specifically for the DTF process, ensuring proper adhesion and vibrant colors. High-quality inks also withstand heat during the transfer process and maintain their integrity through multiple washes, providing long-lasting designs for custom apparel.

| Key Supplies | Description |

|---|---|

| Printer | A dedicated DTF printer designed to use pigment-based inks for vibrant prints. |

| Film | Specialized DTF transfer films that accept inks and enable effective transfer to fabric. |

| Adhesive Powder | A bonding agent that affixes the design to the fabric during heat transfer. |

| Heat Press | Machine to apply heat and pressure for accurate design transfers. |

| Inks | Specially formulated inks that ensure adhesion and vibrant colors suitable for DTF. |

Summary

DTF Supplies play a crucial role in starting your DTF printing journey. With a variety of essential materials such as printers, films, adhesive powders, heat presses, and inks, one can significantly enhance the quality of custom apparel. Mastering DTF printing involves not only gathering the right supplies but also understanding the nuances of the process. As you navigate through this vibrant printing method, leveraging high-quality DTF Supplies will ensure you produce durable and appealing designs that resonate well with customers, positioning you effectively within the competitive custom apparel market.